📌 Key Takeaways

A clear sample well can hide compliance violations that trigger fines, shutdowns, and emergency pump-outs during your busiest service hours.

- Surface Clarity Hides Bottom Risk: The sample well shows only the top layer while heavy sludge accumulates invisibly at the tank bottom, often pushing total accumulation past the 25% threshold.

- Inspectors Measure, Not Eyeball: Core sampling captures the full vertical column of grease cap plus settled solids, providing the accurate percentage calculation that determines compliance.

- Dual Requirements Drive Service Timing: Houston mandates pump-out at 25% accumulation OR every 90 days, whichever comes first—meaning high-volume kitchens may need service before the calendar triggers it.

- Cleaning Without Manifests Means Incomplete Compliance: Signed waste manifests proving legal disposal must be retained for five years and produced on demand during inspections.

- Measured Compliance Replaces Guesswork: Monthly core sampling with documented results transforms reactive crisis management into predictable, scheduled maintenance that keeps operations running smoothly.

Measured beats guessed. Houston restaurant operators and facilities managers will find a practical compliance framework here, preparing them for the detailed implementation guidance that follows.

Friday night. The dinner rush is building momentum, and everything seems fine. You check the sample well—it looks clear. No visible grease floating on top, no obvious warning signs. But then the drains start backing up. Odors rise from the floor sinks. And when the city inspector arrives for a surprise visit, you discover your trap is well past the 25% threshold.

A clear sample well doesn’t guarantee compliance. It only shows what’s happening at the surface while potentially hiding several inches of settled sludge at the bottom of your tank.

What is a sample well? It’s the access point on top of your grease trap that allows you to visually inspect the contents. Think of it as a small window into a much larger system—you can see the top layer, but everything below remains hidden.

Here’s the reality: Judging trap compliance by looking at the sample well is like checking your fryer oil by examining only the top inch. The surface might look golden and clean, but the burnt solids and breakdown products settle to the bottom where you can’t see them.

Picture this common scenario: It’s Friday evening, your dining room is packed, and everything appears to be running smoothly. The sample well you checked this morning looked perfectly clear. But as the night progresses, your dish pit slows down. Water pools around the three-compartment sink. A faint odor begins to drift from the floor drains. Your staff mentions it, but you’re in the middle of service. Then an inspector walks through the door for a routine check. Within minutes, they’re measuring your trap with a core sampler—and the reading shows 32% accumulation. You’re facing a violation notice and an immediate order to pump out, all while your sample well still looks relatively clear from above.

The practical solution: Adopt the inspector’s standard. Use core sampling to measure the full vertical column of your trap contents, capturing both the floating grease cap and the settled solids layer. Schedule regular grease trap cleaning in Houston based on actual measurements, not guesswork. This shift from visual checks to measured compliance transforms uncertainty into predictable, documented maintenance.

What a Sample Well Really Shows (and Hides)

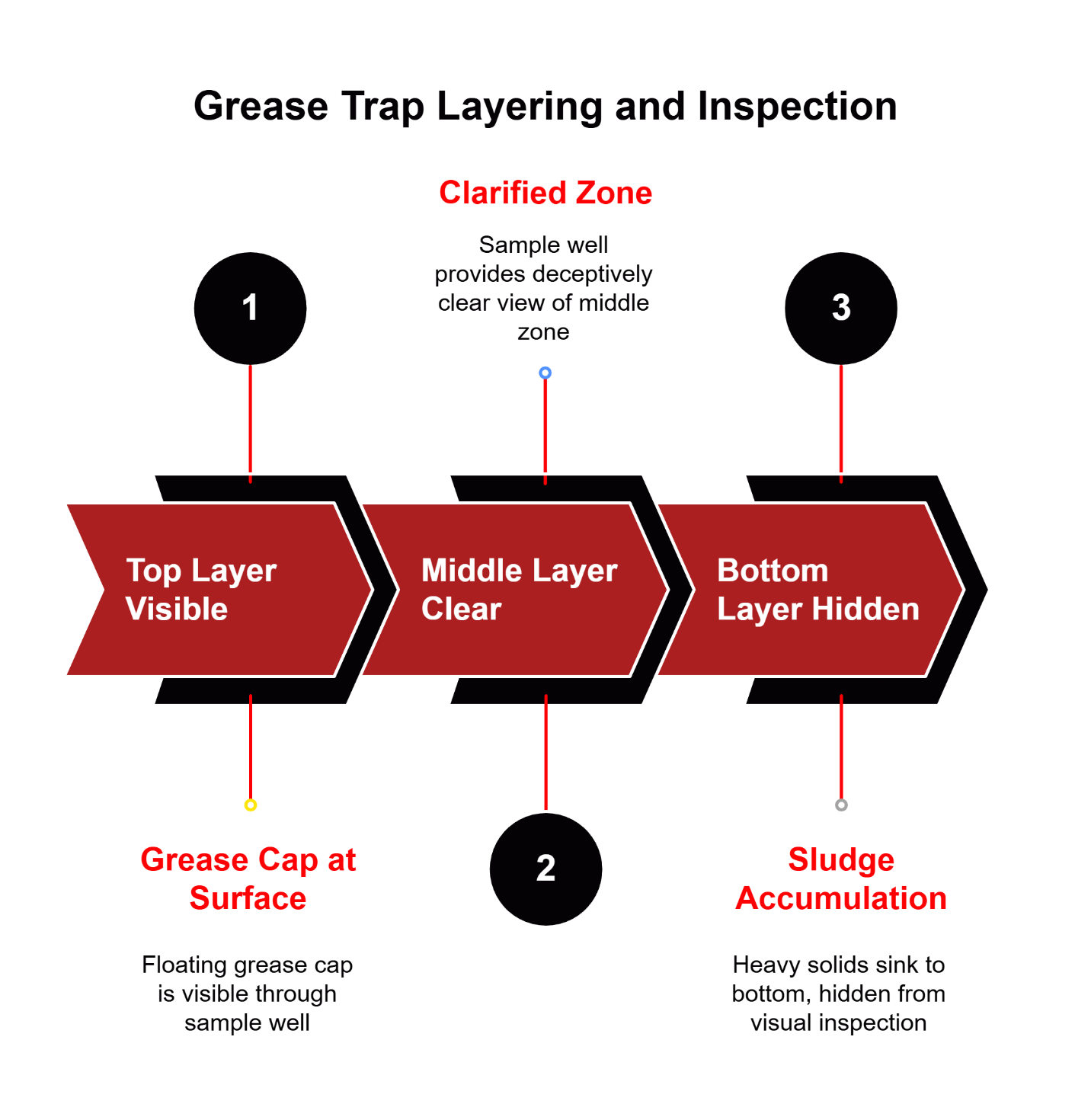

A sample well provides access to the trap’s surface layer. When you lift the lid and look down, you’re seeing the top 2-4 inches of a tank that might be 18-24 inches deep. This limited view reveals the floating grease cap—if one has formed—but tells you nothing about the sludge accumulating below.

The physics of grease trap operation work against visual inspection. Lighter materials—fats, oils, and grease—float to the top, where they’re visible through the sample well. Heavier solids, including food particles, sediment, and degraded organic matter, sink to the bottom and remain completely hidden from view. Between these two layers sits the clarified middle zone where your sample well provides its deceptively clear view.

This layered separation is exactly what the trap is designed to create. But it also creates a dangerous illusion. The visible surface layer might represent only 5-10% greasy appearance, while the bottom sludge layer has accumulated to the point where the combined total exceeds 25% of the wetted depth. The trap can be approaching or exceeding the compliance threshold while the sample well looks perfectly acceptable. Restaurant managers who rely on visual checks alone often discover they’re out of compliance only when an inspector arrives with proper measuring equipment.

Visual Checks vs. Core Sampling (Inspector’s Standard)

Visual checks are incomplete. They capture a single snapshot of the surface without revealing the total accumulation that determines compliance. Core sampling, by contrast, extracts a vertical column of the trap’s contents from top to bottom, providing an accurate percentage of total FOG (fats, oils, grease) and settled solids.

Inspectors don’t guess. They use a core sampler—sometimes called a “sludge judge”—to measure compliance. This simple tool consists of a clear tube with a check valve at the bottom. When inserted through the sample well and pushed to the tank floor, it captures a representative sample of everything: the floating grease, the middle liquid layer, and the bottom sludge. The inspector then calculates what percentage of the trap is occupied by waste versus liquid capacity. FOG inspection programs rely on these core samplers as standard equipment for determining compliance.

Step-by-Step: How to Take a Core Sample

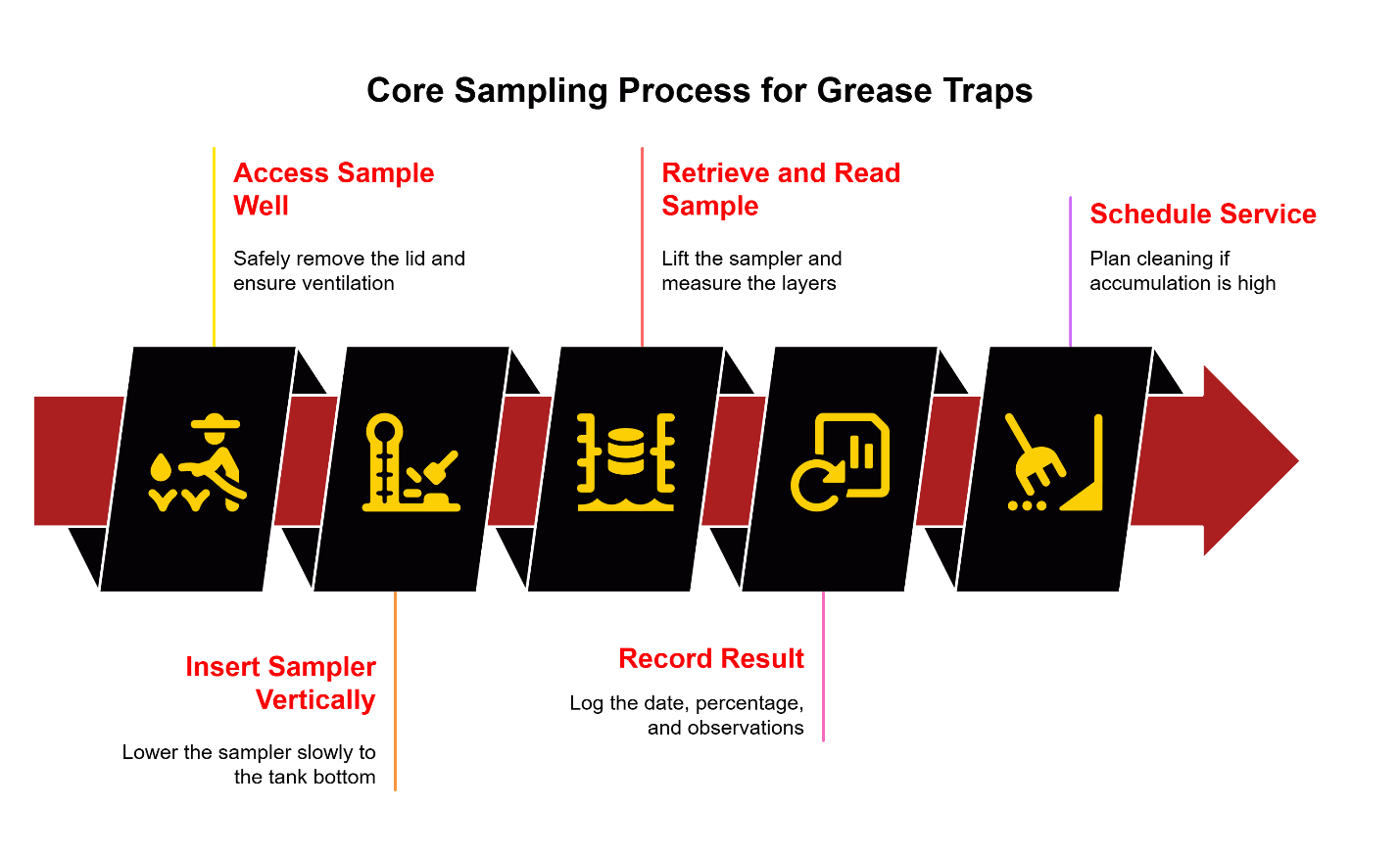

Training your management team to measure like an inspector transforms compliance from reactive to proactive. The process is straightforward:

- Access the sample well safely. Remove the lid and ensure proper ventilation. Never lean directly over an open trap.

- Insert the sampler vertically. Lower the core sampler tube slowly through the sample well opening until it reaches the tank bottom. Keep it as vertical as possible to capture an accurate column.

- Retrieve and read the total percentage. Lift the sampler out carefully. You’ll see distinct layers: grease cap on top, clear zone in the middle, and dark sludge at the bottom. Measure the combined height of the grease cap plus the sludge layer, then divide by the total sample height to get your accumulation percentage.

- Record the result. Log the date, percentage, and any observations (odors, drain performance issues) in your maintenance binder.

- Schedule service before you hit 25%. If your reading shows 20% or higher, it’s time to schedule a commercial grease trap cleaning. Don’t wait until you’re already in violation.

The 25% Rule: The Real Compliance Trigger

Houston’s grease trap regulations operate on a dual-requirement system that protects both your business and the city’s infrastructure. Texas model standards require complete evacuation at 25% of wetted height, measured as the vertical distance from the outlet pipe to the trap bottom. This 25% accumulation threshold represents the mandatory maximum—your trap must be pumped when the combined grease cap and settled solids reach this level, regardless of how much time has passed.

The second requirement establishes the mandatory minimum frequency: grease interceptors must be fully evacuated at least every 90 days, even if measurements show accumulation below 25%. This means whichever limit is reached first triggers the need for service. A high-volume kitchen might hit 25% accumulation in 60 days and need early service, while a slower operation still cannot exceed the 90-day maximum interval regardless of measured percentage.

Understanding what counts toward the 25% calculation is critical. Many restaurant operators mistakenly believe only the floating grease layer matters. In reality, the measurement captures both the grease cap floating on top and the solids layer settled at the bottom. The middle liquid layer does not count toward accumulation, but its depth shrinks as grease and solids increase from both directions. An operator might look at a thin grease layer and assume compliance, while several inches of hidden sludge push the total well past the threshold.

The 25% trigger exists for operational and environmental reasons. Once a trap exceeds this level, its efficiency drops dramatically. FOG begins passing through to the sewer system, increasing the risk of blockages both in your building’s private lines and in the city’s public infrastructure. This is why violations carry serious consequences: fines, mandatory immediate pump-out, and potential closure orders for repeat offenders.

Think of accumulation in three operational zones:

0-20% accumulation: System operating within normal range. Continue monitoring with regular core sampling.

20-25% accumulation: Time to schedule cleaning. This buffer prevents violations if business volume spikes unexpectedly before your next check.

25%+ accumulation: The trap is overdue. Risk of enforcement action increases, and efficiency has already declined.

For most food service operations with typical volume in Houston, these dual requirements converge naturally. The standard quarterly service schedule aligns with both the 90-day mandatory minimum and the typical accumulation pattern that reaches 20-25% within that timeframe. However, schedule alone isn’t enough—you need to verify with actual measurements. A high-volume location might need service every 60 days when hitting 25% accumulation early, while a slower operation must still service at 90 days even if measurements show lower percentages.

Why “Clear Today” Can Be a Fine Tomorrow

Grease trap accumulation isn’t linear or predictable based solely on calendar intervals. Flow patterns, menu changes, staff turnover, and seasonal business fluctuations all affect how quickly your trap fills. What looked acceptable during a slow Tuesday lunch shift can reach violation levels by Friday dinner service.

The “clear sample well” illusion becomes particularly dangerous during busy periods. As your kitchen output increases, both grease and solids accumulate faster. The floating grease layer might not appear dramatically different from day to day, but the bottom sludge layer—invisible from your sample well vantage point—builds steadily. By the time you notice operational symptoms like slow drains or odors, you’re often already past the compliance threshold.

Consider the operational costs of waiting too long. Emergency pump-outs during business hours disrupt service. Violations trigger fines that far exceed the cost of preventive maintenance. Sewage backups can force temporary closure while you address both the trap and any damage to your building’s plumbing system.

“Drain Ranger is very professional and reliable. Basically they can take care of all your grease drain needs.” — Shelley M.

Proof Matters: Cleaning + Manifesting = Total Compliance

Pumping out your grease trap removes the waste, but documentation proves legal disposal. Inspectors don’t just want to see that your trap is clean—they need evidence that the waste was handled according to environmental regulations.

This is where manifesting becomes essential. A waste manifest is a multi-part form that tracks your grease trap waste from pickup through final disposal. The hauler provides a signed copy showing the date of service, the amount of waste removed, and confirmation of disposal at an approved facility. Keep these manifests in an accessible binder at your location.

Houston restaurant operators should retain manifests for at least five years, reflecting the city’s commitment to comprehensive FOG compliance documentation. During inspections, being able to immediately produce service records demonstrates professional management and often influences how inspectors approach borderline situations.

Pairing measurement with documentation creates a complete compliance system. You measure to know when service is needed, you schedule before violations occur, and you retain manifests to prove every load was disposed of legally. This three-part approach—measure, service, document—transforms compliance from a reactive scramble into a predictable operational routine.

“My experience with Drane Ranger was a very organized, professional and on time experience. I was kept informed of what was happening and a suggested time of cleaning again. I will use them again and will definitely recommend them to anyone I speak with.” — Harold R.

What Houston Restaurants Should Do Now

Move from visual guessing to measured compliance with this four-point checklist:

Train managers on core sampling. Designate at least two people on your team who know how to take a proper core sample. Schedule monthly measurements and record every result in your compliance binder.

Establish your trigger point. Once your measurements consistently show 20% accumulation, schedule service. This buffer prevents violations if business volume spikes unexpectedly before your next scheduled cleaning.

Set up recurring service with dual-requirement awareness. For most locations within Houston city limits, quarterly service satisfies both the 90-day mandatory minimum and typical accumulation patterns. Work with a registered hauler who provides detailed manifests for every pump-out and understands that service timing must respond to whichever requirement is reached first.

Keep your compliance binder current and accessible. Store manifests, measurement logs, and service invoices together in one location. Remember that Houston requires five-year manifest retention. When an inspector arrives, you should be able to produce complete documentation within minutes.

Ready to move beyond guesswork? Schedule inspector-grade sampling and cleaning with a registered Houston hauler or call 281-489-1765 (Mon-Fri, 9am-6pm) to set up quarterly service with full manifesting.

Frequently Asked Questions

Is a clear sample well proof my trap is compliant?

No. Visual checks miss the bottom sludge layer. Only core sampling reveals total accumulation including both the grease cap and settled solids.

What exactly counts toward the 25% rule?

Both the floating grease cap and the settled solids layer at the tank bottom. Together, these cannot exceed 25% of the trap’s wetted height—the vertical distance from the outlet pipe to the trap bottom.

How often should I pump my grease trap?

Houston requires service based on whichever limit is reached first: 25% accumulation or 90 days, whichever comes sooner. Most food service operations with typical volume hit both thresholds around the same quarterly timeframe, but high-volume locations may need more frequent service based on measured accumulation.

Do I need paperwork after cleaning?

Yes. Keep signed waste manifests that prove legal disposal. Store these in an accessible compliance binder for inspections and retain them for at least five years—Houston’s requirement that exceeds the three-year federal standard.

Disclaimer: This article provides general educational information about grease trap compliance practices in Houston. Requirements may vary based on your specific location, trap size, and operation type. Always consult current municipal codes and work with registered waste haulers to ensure full compliance with local regulations.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team synthesizes complex compliance topics into clear, actionable guidance for Houston-area food service operators. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace consultation with qualified professionals. Drane Ranger serves all zip codes within a 100-mile radius of Houston with grease trap cleaning, maintenance services, and full compliance documentation.