📌 Key Takeaways

Houston’s quarterly grease trap cleaning requirement is a compliance system combining scheduled service with inspection-ready documentation that prevents both operational shutdowns and regulatory fines.

- 90-Day Baseline Plus Measurement Trigger: Houston mandates full trap evacuation every 90 days minimum, but high-volume kitchens must service immediately when floating grease plus settled solids reach 25% of total liquid depth—often within 60 days.

- Documentation Prevents Citations: Inspectors may arrive unannounced requesting permits and five years of waste manifests; missing paperwork triggers fines even when your physical trap is clean.

- Complete Service Goes Beyond Pumping: Proper maintenance removes all FOG and sludge, cleans the sample well, inspects baffles, verifies flow, and provides manifests with hauler license numbers and disposal facility documentation.

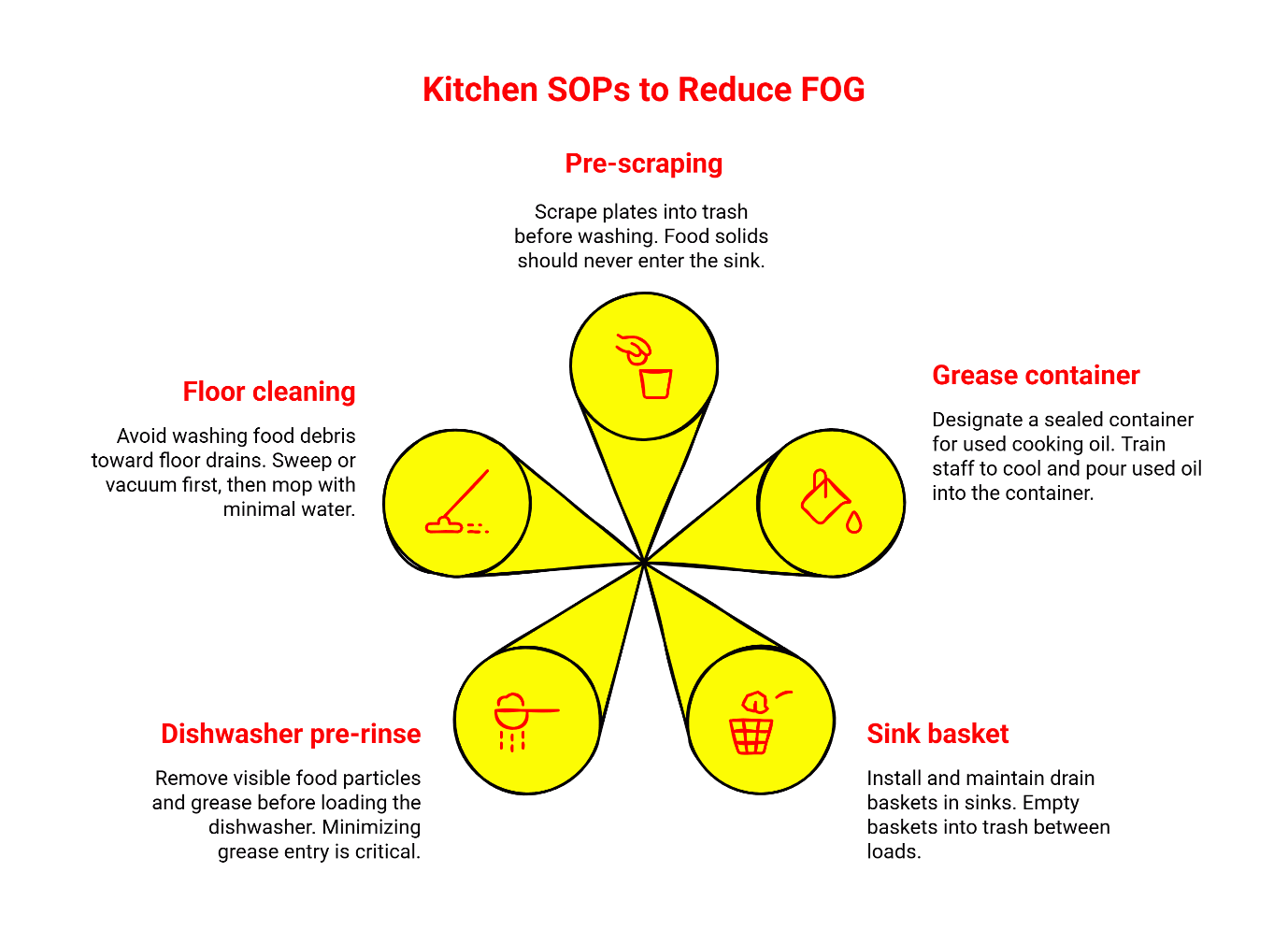

- Kitchen SOPs Extend Service Intervals: Pre-scraping plates, using sealed grease containers, maintaining drain baskets, and proper dishwasher loading reduce FOG accumulation between scheduled cleanings.

- Emergency Thresholds Require Immediate Action: Call your provider immediately when you observe standing water in multiple drains, persistent strong odors, visible backups, or simultaneous slow drainage across different kitchen areas.

Scheduled maintenance plus organized documentation equals operational predictability without emergency shutdowns.

Houston restaurant owners and managers will gain a complete compliance framework here, preparing them for the implementation tools that follow.

Friday night, 7:30 PM. The dining room is full. Then you smell it—that unmistakable sour odor drifting from the kitchen. The dishwasher reports slow drainage. You realize the grease trap is overloaded, and you have no idea when it was last serviced. Worse, you remember seeing a notice about city inspections requiring documentation you’re not sure you have.

Commercial grease trap maintenance in Houston is a compliance system, not a one-time pump-out. It combines regular physical cleaning with inspection-ready documentation that protects your business from both operational disruptions and regulatory penalties. Think of it as an oil change for your restaurant’s plumbing engine—a routine service that prevents catastrophic failures and keeps everything running smoothly. The practical application is straightforward: schedule routine service based on the city’s quarterly baseline, and keep manifests accessible in a compliance binder that any manager can present on demand.

Houston’s Reality: Grease Trap Maintenance Is a Compliance System, Not a One-Time Pump-Out

In Houston, maintenance represents a routine compliance obligation tied to inspections, permits, and documentation—not just a service you call when problems appear. Restaurants with grease traps operate as special waste generators under city regulations, which means your trap falls under specific evacuation and record-keeping requirements that inspectors will verify.[1]

The baseline requirement is clear: grease interceptors within city limits must be fully evacuated at least every 90 days unless you hold an approved waiver.[1] This quarterly standard exists because fats, oils, and grease accumulate predictably in commercial kitchen wastewater, and the city’s sewer infrastructure depends on businesses preventing FOG from entering the municipal system. Your permit is valid for one year and must be renewed annually to maintain compliance.[1]

Treat this like a recurring operating procedure. Put service dates on your calendar the same way you schedule health inspections or equipment maintenance. Create a compliance binder—physical or digital with printed copies—that contains your current permit, waste manifests, and service invoices. Train at least two managers to know where this binder lives and what it contains, because inspections can occur without advance notice.

The city’s enforcement framework includes a measurement threshold often referenced as the “25 percent standard.”[2] When the combined depth of floating grease plus settled solids reaches 25 percent of the trap’s total liquid depth(), service is required regardless of when your last cleaning occurred. This measurement-based trigger means high-volume operations may need service more frequently than the quarterly minimum.

The Two Failures That Get Houston Restaurants Hurt: Backups/Odors and Paperwork Gaps

Physical overfill causes immediate operational disruption, while missing documentation creates compliance exposure that can trigger fines even when your trap is clean. Understanding both failure modes helps you build a defense system that addresses the full risk spectrum.

Operational Failure Mode

When grease accumulates beyond your trap’s capacity, you’ll see the warning signs in your daily operations. Slow drains appear first—the three-compartment sink takes longer to empty, or standing water persists near floor drains. Odors follow, starting as a faint sour smell that intensifies during peak service hours. Eventually, you face backups that force you to stop operations, cancel reservations, and potentially close the kitchen until the problem is resolved. Each hour of downtime represents lost covers and revenue you cannot recover.

The operational costs extend beyond immediate lost business. You may need emergency service at premium rates. Staff morale suffers when they’re working in unsanitary conditions. Customer reviews mention the odor, damaging your reputation in ways that persist long after the trap is cleaned.

Compliance Failure Mode

The documentation side creates a different kind of vulnerability. Inspectors may arrive unannounced and request to see your permit, waste manifests for the past five years, and related documentation that proves proper waste handling.[1] If you cannot produce these records immediately, you face citations regardless of how clean your physical trap appears at that moment.

Poor retention discipline—failing to collect manifests from your hauler, losing invoices, or simply not knowing where documents are stored—creates gaps that inspectors will identify. The trap itself might be spotless, but without the paper trail proving compliant disposal, you have no defense. This documentation must demonstrate that waste was transported by a licensed hauler and disposed of at an approved facility.

Build a two-lane system that addresses both dimensions. Your cleaning schedule ensures physical capacity (Lane 1: service cadence), while your documentation routine ensures audit readiness (Lane 2: documentation discipline). Clean isn’t compliant until it’s documented.

How Often Should You Service a Commercial Grease Trap in Houston?

Start with the 90-day evacuation baseline as your strict minimum frequency, then adjust based on your specific volume, menu composition, and measurement triggers. The law establishes 90 days—not a calendar quarter—as the default maximum interval, but your operational reality may require more frequent service.

Several practical factors influence your actual service needs. Fryer-heavy menus generate substantially more FOG than operations focused on grilling or steaming. High-volume dishwashing with inadequate pre-scraping sends excess grease into your drainage system. The number of seats you serve and your typical service turns per shift directly affect waste generation rates. Seasonal spikes—holiday catering, summer patio service, special events—temporarily increase FOG loads beyond your baseline.

Use the maintenance schedule template below as your starting framework. After the first three service cycles, review the measurements your hauler reports. If your trap consistently reaches 20 percent accumulation within 60 days, move to a bimonthly schedule. Conversely, if measurements show minimal accumulation at 90 days, you may qualify for a waiver that extends your interval—though this requires formal approval and documentation.[1]

Pay attention to operational signals between services. If you notice any slow drainage or faint odors before your scheduled service date, that’s your trap telling you it needs attention sooner. Don’t wait for the calendar; call your provider and adjust your future schedule accordingly.

What “Good Maintenance” Actually Includes (Beyond Pumping)

True maintenance removes all FOG and settled solids, restores full hydraulic function, and leaves your system inspection-ready—including clear access to the sample well for measurement verification. Simply pumping liquid from the trap without addressing the sludge layer or confirming proper flow accomplishes only part of the job.

A complete service should include several key steps. The technician pumps out all liquid waste and sludge from every chamber of your trap. They inspect and clean the sample well, which inspectors may check during audits. They verify that inlet and outlet baffles are intact and functioning properly, since damaged baffles allow FOG to escape into the sewer system. They confirm proper flow by running water through your drain system and observing that the trap fills and discharges correctly.

Before the service truck leaves your property, use this post-service checklist to verify completion:

- The technician provided you with a trip ticket or manifest that includes the date, volume removed, disposal facility information, and hauler license number

- The sample well is clean and accessible

- Water flows freely through your drain system with no backup

- The technician noted any mechanical issues or damage that requires repair

- You received guidance on when the next service should occur based on what they observed

The Sample Well Myth

Many operators believe that checking the sample well provides a complete picture of trap condition. A clear-looking sample well can be misleading—grease floats on top and sludge settles at the bottom, potentially creating a deceptively clean-looking middle layer that the sample well reveals. Inspectors may use core sampling techniques that measure the full vertical column of your trap’s contents to determine actual FOG accumulation. This distinction matters because a visual check might suggest you’re compliant when measurement would reveal you’ve exceeded the 25 percent threshold.

Inspection Readiness: What Houston Investigators May Ask to See

Inspections may occur without advance notification, and you must be prepared to present your permit plus supporting documentation immediately. The city’s enforcement approach assumes that proper documentation should be readily available at your facility, not stored offsite or requiring time to locate.

Keep these documents organized and accessible in what many operators call a “Compliance Binder”:

- Your current grease trap permit showing it’s active and not expired (permits are valid for one year and must be renewed annually[1])

- Waste manifests covering at least the past five years, organized chronologically so you can quickly find any requested date range[1]

- Any approved waiver documentation if you operate on an extended service interval

- Copies of prior inspection reports with any corrective actions noted and resolved

- Service invoices that correspond to the manifests, proving you paid for legitimate disposal[1]

A practical binder setup that works in real restaurant environments uses this structure: place your current permit and renewal date in the front sleeve where it’s immediately visible. Use tabs to organize manifests by year (Manifests Year 1 through Year 5). Create a separate tab for waivers and any regulatory correspondence. Add another tab for inspection forms and follow-up documentation. Keep a pocket in the back with your current vendor contact card and emergency service number.

Store this binder in a consistent location that multiple managers know about—typically in the manager’s office or a designated document area in the kitchen. When an inspector arrives, any manager on duty should be able to retrieve and present these documents within a few minutes. The inspection may also include physical checks of the trap itself and surrounding waste handling areas, so maintaining both documentation and physical cleanliness protects you from all angles.[1]

Some operators maintain dual systems: a physical binder for immediate access and a digital backup stored in cloud storage. This redundancy ensures you never lose critical compliance records to fire, flood, or simple misplacement.

Vendor Selection in Houston: How to Avoid the “Cheap Hauler” Trap Without Overpaying

Choose vendors who can consistently service on schedule and provide defensible documentation that protects you during inspections. Price matters, but the lowest bid often excludes the compliance protections that prevent far more expensive problems.

Here’s why the cheapest option can create liability. If your hauler doesn’t dispose of waste at approved facilities or fails to provide proper manifests, you remain responsible when inspectors find gaps in your documentation. The money you saved on service costs becomes meaningless when you’re facing fines or forced to reconstruct records you never received. Your vendor’s reliability directly affects your compliance status.

The “call when it smells” approach sounds simpler than scheduling regular service, but smell represents a late-stage warning signal. By the time odors are noticeable, you’re likely already approaching or exceeding the measurement threshold. You’ve also lost the predictability that scheduled maintenance provides—instead of planning for known service dates, you’re reacting to problems that always seem to appear during your busiest periods. Scheduled maintenance prevents these emergencies rather than merely responding to them.

Use this vendor scorecard to evaluate your options:

Licensing and Credentials: Can they show you their waste hauler license and disposal facility certifications? Are they registered with the city as an approved grease trap service provider?

Manifesting Process: Do they provide detailed manifests after every service that include all required information? Can they explain their documentation process clearly?

Disposal Transparency: Will they tell you exactly which facility receives your waste? Can they provide proof of proper disposal if an inspector questions your records?

Scheduling Reliability: Do they offer recurring service contracts with guaranteed windows? What’s their policy if they miss a scheduled appointment?

Emergency Response: If you call with an urgent issue, how quickly can they respond? What are their after-hours or weekend service options?

Communication Standards: Will they notify you in advance of scheduled service? Do they provide measurement data showing accumulation levels?

Training and Certification: Are their technicians trained in proper trap servicing techniques? Do they understand Houston’s specific requirements?

Equipment Quality: Do they maintain modern vacuum trucks capable of complete evacuation? Can they handle the size and type of trap you operate?

Insurance Coverage: Do they carry adequate liability insurance that protects your property during service?

Reference Check: Can they provide references from similar operations in Houston? How long have they been serving the area?

A mid-range provider who consistently delivers clean service with complete documentation represents better value than a discount operation that creates compliance gaps you’ll spend time and money resolving later.

Daily Kitchen Habits That Reduce FOG Load (Commercial SOPs, Not DIY)

Staff behaviors significantly influence how much FOG enters your drainage system, which directly affects how quickly your trap fills and how often you need service. Implementing standard operating procedures around waste handling stabilizes your service intervals and reduces the likelihood of operational problems between cleanings.

The Environmental Protection Agency identifies FOG as a leading contributor to sanitary sewer overflows and supports prevention programs at the source.[3] The Texas Commission on Environmental Quality provides model ordinance guidance that establishes best practices for commercial FOG management, emphasizing the importance of kitchen procedures that complement proper trap maintenance.[4]

Establish these SOP rules and assign specific staff members to own training and enforcement:

Pre-scraping requirement: All plates, pots, and pans must be thoroughly scraped into trash or compost bins before washing. Food solids and visible grease should never enter the sink or dishwasher.

Grease container protocol: Designate a sealed container for used cooking oil near fryers and cooking stations. Train staff to cool and pour used oil into this container rather than down any drain. Arrange regular pickup for full containers through your cooking oil recycling vendor.

Sink basket discipline: Install and maintain drain baskets in all three-compartment sinks. Staff must empty these baskets into trash between each load rather than letting solids accumulate and eventually pass through.

Dishwasher pre-rinse standards: Before loading the commercial dishwasher, staff should remove all visible food particles and grease. High-temperature dishwashers can temporarily emulsify FOG, preventing it from separating effectively within the trap and allowing it to pass through to the city sewer. Minimizing grease entry at this stage is critical for both trap efficiency and compliance.

Floor cleaning procedures: When cleaning kitchen floors, avoid washing large amounts of food debris toward floor drains. Sweep or vacuum first, then mop with minimal water. Never pour mop bucket water containing grease or food particles down drains.

Make these expectations part of new employee orientation and include them in regular training refreshers. When managers observe non-compliance, correct it immediately and document the coaching. Staff members who understand why these rules exist—protecting their workplace from shutdowns and maintaining a sanitary environment—become active participants in compliance rather than seeing SOPs as arbitrary restrictions.

The Printable Maintenance Schedule Template

A simple schedule prevents missed service dates and supports audit readiness by creating a single document that tracks your compliance history. Print this template, post it in your manager area, and update it after each service.

Grease Trap Maintenance Schedule

Facility Information

- Restaurant name: ________________________

- Trap location/ID: ________________________

- Trap capacity (gallons): ________________________

Service Schedule

- Target frequency: ☐ Monthly ☐ Every 60 days ☐ Quarterly ☐ Other: _______

- Last service date: ________________________

- Next service due: ________________________

Service Provider

- Vendor company name: ________________________

- Primary contact: ________________________

- Phone number: ________________________

- License number: ________________________

Post-Service Checklist (Complete after each service)

- Date service performed: ________________________

- Volume removed (gallons): ________________________

- Manifest received: ☐ Yes ☐ No (Manifest number: _______)

- Disposal facility documented: ☐ Yes ☐ No

- Binder updated with new records: ☐ Yes ☐ No

- Sample well cleaned and accessible: ☐ Yes ☐ No

- Technician noted any issues: ☐ Yes ☐ No (Details: _______________)

Operational Notes

- Drain speed between services: ☐ Normal ☐ Slower than usual ☐ Problematic

- Odors detected: ☐ None ☐ Occasional ☐ Persistent

- Any backups or overflow: ☐ No ☐ Yes (Date/location: _______________)

- Schedule adjustment needed: ☐ No ☐ Yes (More frequent / Less frequent)

Manager Signature: ________________________ Date: __________

Keep completed schedules in your compliance binder for at least five years to match the city’s record retention requirement.[1] This simple tool transforms abstract compliance obligations into a concrete workflow that any manager can follow.

When to Call for Help Immediately (Emergency Thresholds)

Certain symptoms indicate imminent disruption risk that requires fast action rather than waiting for your next scheduled service. Recognizing these thresholds helps you prevent downtime and protect your operation from forced closures.

Call your service provider immediately if you observe:

- Standing water in multiple drains that won’t clear even after you stop running water. This suggests your trap has reached capacity and backflow is beginning.

- Persistent strong odors that intensify throughout the day and don’t dissipate when you improve ventilation. Odor indicates FOG is decomposing in your trap or lines, which means accumulation is significant.

- Visible grease or sewage backing up into sinks, floor drains, or equipment areas. Once backup begins, you’re hours away from potential health code violations or customer-visible problems.

- Multiple slow drains simultaneously across different areas of your kitchen. If only one drain is slow, you may have a localized clog, but multiple affected drains suggest your trap is the bottleneck.

While waiting for emergency service, take these protective steps:

- Protect floor surfaces from potential overflow by placing absorbent materials nearby

- Stop sending water down affected drains where possible (pause dish station output briefly)

- Notify your front-of-house manager so they can plan service adjustments if the kitchen’s capacity is reduced

- Pull your compliance binder and service history to have ready when the technician arrives

Document what you observe with photos and notes—this information helps your provider respond appropriately and may also serve as evidence of your good-faith efforts if any compliance questions arise.

Emergency situations should be rare if you’re maintaining your scheduled service cadence and watching for early warning signs. If you find yourself calling for emergency pump-outs frequently, that’s a clear signal to increase your service frequency.

Building Your Path to Operational Peace of Mind

The transition from reactive “call when it smells” management to proactive compliance delivers three concrete outcomes that directly improve how your restaurant operates day-to-day.

Predictable operations mean you control when service occurs rather than having emergencies dictate your schedule. You can arrange maintenance during slow periods when kitchen disruption matters least. Your staff works in a sanitary environment without odors or drainage problems that make their jobs harder. You avoid the revenue loss and reputation damage that comes from being forced to reduce capacity or close temporarily because of backup issues.

Audit readiness transforms inspections from stressful events into routine interactions. When an inspector arrives, your managers can immediately present organized documentation that proves compliant service and proper disposal. You demonstrate that you take your responsibilities as a special waste generator seriously, which builds credibility with regulators. The time you might have spent scrambling to reconstruct records or explain gaps is instead time you spend running your business.

Reduced backup risk provides the confidence that comes from knowing your drainage system can handle your operational demands. You avoid the 2 AM phone call about sewage in the kitchen. You don’t face the nightmare scenario of having a packed dining room while your kitchen is dealing with an overflow. You protect your investment in equipment, flooring, and facilities from the damage that backups cause.

This isn’t theoretical peace of mind—it’s the practical difference between operating with constant background anxiety about your grease trap and knowing that your system is maintained, documented, and reliable. As one restaurant manager shared after implementing a scheduled maintenance program (operations signal), “My experience with Drane Ranger was a very organized, professional and on time experience. I was kept informed of what was happening and a suggested time of cleaning again. I will use them again and will definitely recommend them to anyone I speak with.”

The path forward is straightforward. Print the maintenance schedule template this week. Contact a qualified service provider who can demonstrate proper licensing and manifesting procedures. Schedule your first service or confirm when your next scheduled service will occur. Create your compliance binder with current documents. Train your team on the kitchen SOPs that reduce FOG load between services.

Houston’s compliance system isn’t designed to trap you—it’s designed to protect the city’s infrastructure while ensuring that businesses maintain sanitary operations. When you work with that system rather than against it, maintenance becomes routine rather than overwhelming.

Start Your Service Today

Drane Ranger has served Houston restaurants and commercial facilities since 1985, providing grease trap cleaning services that keep operations compliant and running smoothly. Our team handles the maintenance while you focus on your business.

Call 281-489-1765 to schedule your service or request a quote. We serve the Greater Houston area and provide the documentation you need to stay audit-ready.

Visit our grease trap cleaning services page to learn more, or contact us with questions about your specific needs. For emergency situations, view our emergency services information.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.

References

[1] City of Houston, Permitting Center. “Grease Interceptor Generator Responsibilities.” Houston Permitting Center. https://www.houstonhealth.org/media/271/download

[2] City of Houston, Code of Ordinances. “Chapter 47 – Utilities, Article VI – Wastewater.” Municode Library. https://library.municode.com/tx/houston/ordinances/code_of_ordinances

[3] U.S. Environmental Protection Agency. “Fats, Oils, and Grease (FOG).” Environmental Protection Agency. https://www.epa.gov/system/files/documents/2023-10/fog-slides.pdf

[4] Texas Commission on Environmental Quality. “Model Standards for Grease Interceptors.” TCEQ. https://www.tceq.texas.gov/assistance/water/wastewater/fog/modelstandards.html