📌 Key Takeaways

First 60 Minutes Determine Success or Catastrophe: When grease trap failure strikes during peak service, your immediate response protocol can mean the difference between a manageable incident and permanent business disruption. Stop food preparation immediately, document everything with photos for insurance and health inspectors, and contact certified emergency services within 15 minutes—don’t wait to see if the situation improves.

Three Warning Signs Prevent Emergency Situations: Monitor for slow drainage throughout multiple kitchen areas, persistent foul odors that intensify during busy periods, and visible grease appearing in floor drains or unexpected locations. These indicators typically appear well before complete system breakdown, giving you time to schedule maintenance during slow periods rather than facing crisis during peak service.

Professional Emergency Services Require Strategic Vetting: Before crisis strikes, establish relationships with certified providers who can guarantee response times, provide proper licensing for commercial grease trap pumping in Texas, and offer comprehensive documentation for regulatory compliance. Companies that handle both trap pumping and contamination cleanup prevent you from managing multiple vendors during emergencies.

Documentation Protects Against Future Regulatory Challenges: Essential compliance records include waste disposal documentation, before-and-after service verification, sanitization confirmation for affected areas, and detailed incident timelines. Health departments may investigate grease trap incidents after they occur, and proper documentation demonstrates environmental compliance and food service safety protocols.

Crisis Management Skills Build Leadership Foundation: Emergency preparedness transforms restaurant managers from reactive crisis fighters into proactive risk managers, with standardized protocols becoming invaluable for regional management roles overseeing multiple locations.

This comprehensive emergency response framework provides immediate crisis control while building operational resilience that prevents most emergencies through proper preventative maintenance and staff training on Houston’s commercial grease trap requirements.

The lunch rush is in full swing when you notice it—that unmistakable smell wafting from the kitchen. Within minutes, greasy water starts pooling near the prep stations. Your grease trap has failed, and sewage is backing up onto the kitchen floor just as your busiest service period hits its peak.

This scenario strikes fear into every restaurant operations manager for good reason. A grease trap failure doesn’t just create a mess—it threatens immediate business closure, lost revenue, and potential health department violations that could take considerable time to resolve.

But here’s what separates prepared managers from those who panic: having a clear, actionable emergency response plan. (Because when crisis hits, you don’t have time to figure things out on the fly.)

The following guide provides you with exactly that—a step-by-step protocol to regain control, minimize losses, and protect your operation’s future.

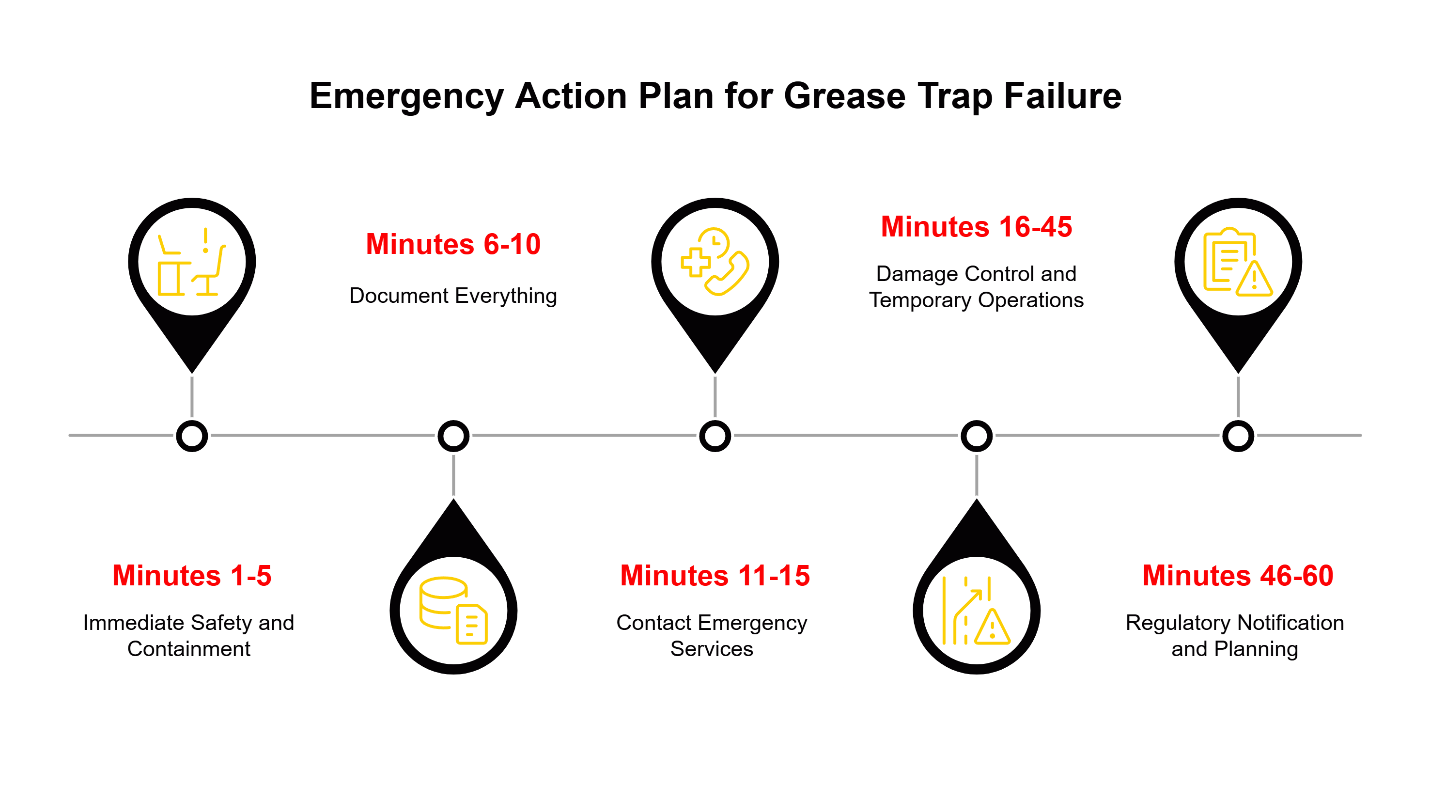

The First 60 Minutes: Your Emergency Action Plan

When grease trap failure strikes, the first hour determines whether you’re looking at a manageable incident or a catastrophic business disruption. Every minute counts, and every action must be deliberate.

Step 1: Immediate Safety and Containment (Minutes 1-5)

Stop all food preparation in the affected areas immediately. Your first priority isn’t the lost revenue—it’s preventing contamination that could shut you down permanently. Block access to contaminated zones using whatever barriers you have available: chairs, wet floor signs, or rope. Alert all staff to avoid the area while you assess the situation.

Step 2: Document Everything (Minutes 6-10)

Take photos of the backup from multiple angles before touching anything. These images become crucial for insurance claims and proving the timeline to health inspectors. Note the time, extent of contamination, and any food that may have been compromised. This documentation protects you legally and financially—don’t skip it even when pressure mounts.

Step 3: Contact Emergency Services (Minutes 11-15)

Call a certified commercial grease trap cleaning service immediately. Don’t wait to see if the situation improves on its own—it won’t. When you call, specify that you need emergency response, not routine maintenance. Request their estimated arrival time and any specific information they need about your situation.

Step 4: Damage Control and Temporary Operations (Minutes 16-45)

Assess which parts of your kitchen remain functional. Can you operate with limited menu options? Set up temporary workflows that bypass the contaminated areas entirely. Contact your manager or owner to discuss whether to close temporarily or operate with restrictions. This decision impacts both immediate revenue and long-term reputation.

Step 5: Regulatory Notification and Planning (Minutes 46-60)

Determine whether you must notify the health department based on the extent of contamination. Research your local requirements, as any sewage backup that affects food preparation areas may require immediate reporting. Plan your communication strategy—both for regulators and customers. Transparency now prevents bigger problems later.

Business Impact

A properly executed emergency response can significantly reduce downtime compared to unmanaged crisis situations. The difference between quick, organized action and chaotic response often determines whether an incident becomes a manageable expense or a major operational disruption. Quick action also demonstrates regulatory compliance awareness, potentially helping your case if inspectors investigate.

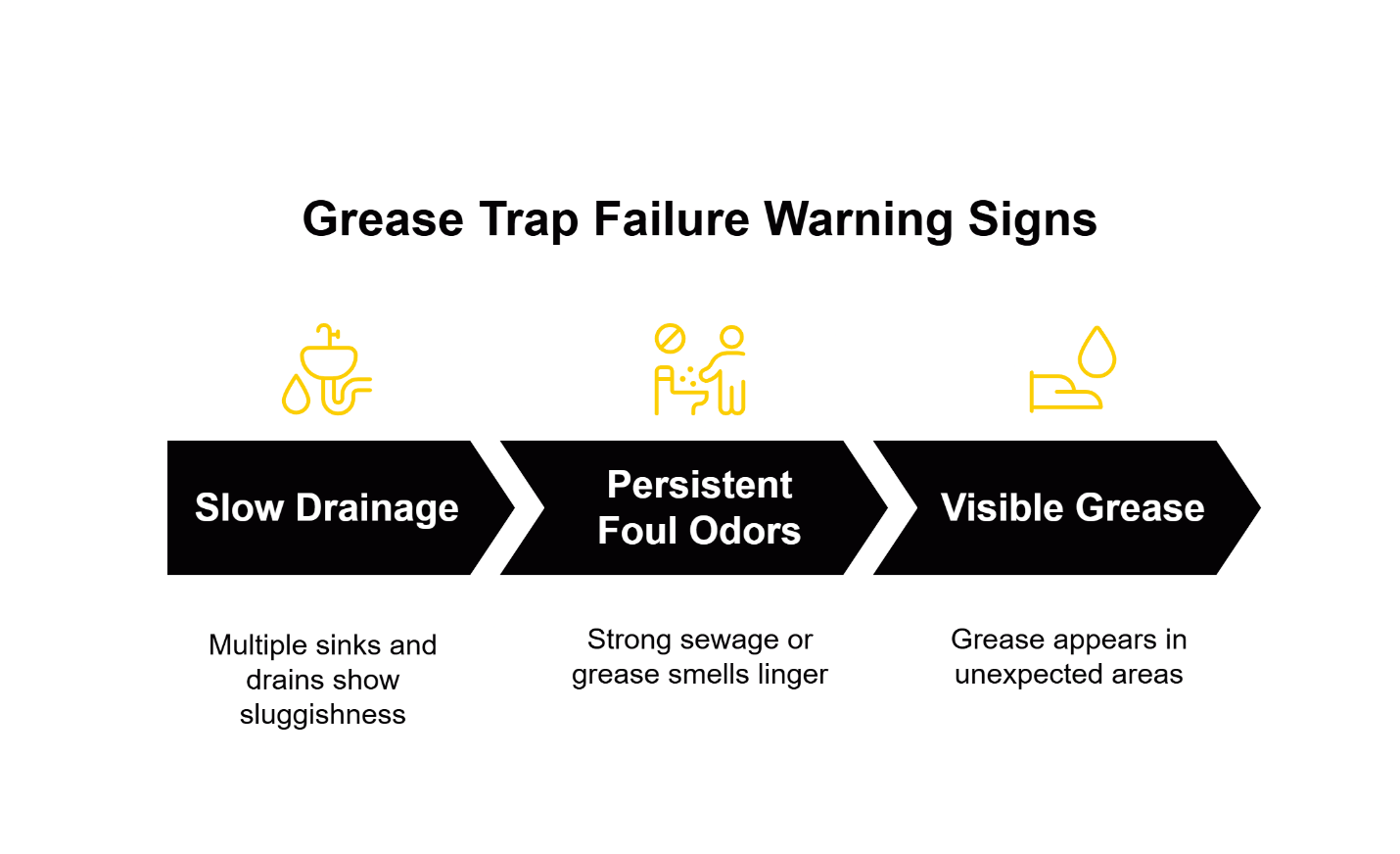

Are You at Risk? 3 Telltale Signs of Imminent Grease Trap Failure

Prevention beats emergency response every time. Smart operations managers watch for early warning signs rather than waiting for catastrophic failure. These indicators typically appear well before complete system breakdown—giving you time to schedule maintenance during slow periods rather than facing emergency situations during peak service.

Slow Drainage Throughout the Kitchen

When multiple sinks and floor drains start backing up simultaneously, your grease trap likely approaches capacity. This isn’t about a single clogged drain—it’s systemic sluggishness that affects the entire kitchen’s wastewater flow. The problem compounds quickly: what starts as slightly slow drainage can become complete backup without intervention.

Persistent Foul Odors Near Trap Locations

Strong sewage or grease odors that don’t dissipate after normal cleaning indicate trapped waste reaching concerning levels. These smells often intensify during busy periods when more wastewater flows through the system. Don’t mask odors with air fresheners—they signal an underlying problem requiring attention.

Visible Grease in Floor Drains or Unexpected Areas

Grease appearing in floor drains, around prep sinks, or backing up through unexpected drainage points means your trap can no longer contain what it’s designed to process. This visible overflow represents a warning sign that system failure may be approaching.

Technical Note

Houston requires regular grease trap maintenance for commercial establishments, but high-volume restaurants often need more frequent service than minimum requirements. Monitor these warning signs regularly rather than relying solely on scheduled maintenance—early intervention typically costs less than emergency response.

Choosing Your Lifeline: How to Vet a 24/7 Emergency Service in Houston

During a crisis, desperation makes poor decision-making easy. Calling the first number found online often leads to problems with service quality, pricing transparency, or inadequate cleanup. Instead, ask these five critical questions before committing to any emergency service:

What’s your typical response time for emergency calls?

Professional emergency services should provide realistic timeframes for Houston-area response. Ask about their current availability and any factors that might affect arrival times. Companies that can’t provide any estimate may lack the capacity for true emergency response.

Are you licensed for commercial grease trap pumping in Texas?

This isn’t just bureaucratic checking—proper licensing indicates companies follow appropriate disposal methods and understand regulatory requirements. Request license information and ask about their compliance procedures.

What documentation will you provide for regulatory compliance?

Professional services should provide appropriate documentation of their work, including waste disposal records and service verification. These documents may be important if health inspectors investigate. Companies that can’t explain their documentation process may not understand compliance requirements.

Do you handle contaminated area cleanup, or just the trap pumping?

Some services only address the trap itself, leaving you responsible for sanitizing affected areas. Clarify exactly what services are included in emergency response. Full-service providers typically handle both trap pumping and contamination cleanup.

What’s your cost structure for emergency response?

Emergency service typically costs more than routine maintenance, but professional companies should provide clear pricing information upfront. Be cautious of services that won’t discuss costs until they arrive on-site.

Day-to-Day Application

Create a contact list of pre-vetted emergency services before crisis strikes. Research and interview potential providers during calm periods when you can make rational decisions. Having established relationships with certified grease trap service providers means better response when emergency situations arise.

Common Pitfalls to Avoid When Responding to a Grease Trap Emergency

Even well-intentioned managers make costly mistakes during high-stress situations. These common errors can transform manageable incidents into major problems—often with consequences that extend well beyond the initial situation.

Waiting Too Long to Call Professional Help

The “let’s see if it gets better” approach rarely works with grease trap failures. What seems like a minor backup in the morning can become a major flooding situation during busy service periods. Early professional intervention usually prevents situations from escalating to the point where health departments become involved.

Attempting DIY Fixes with Inappropriate Tools

Restaurant staff shouldn’t attempt to snake, plunge, or chemically treat backed-up grease traps. These approaches often push contamination deeper into the system, making professional cleanup more difficult. Additionally, inappropriate chemicals can damage trap components, potentially requiring replacement rather than cleaning.

Continuing Food Service in Compromised Areas

The temptation to “work around” contaminated areas during busy periods creates serious health code risks. Cross-contamination between clean and contaminated zones happens easily in commercial kitchens. Temporary closure typically creates fewer problems than extended health department investigations.

Inadequate Documentation of the Incident

Taking insufficient photos or failing to document the timeline creates problems when dealing with insurance claims or regulatory questions. Thorough documentation of contamination extent, affected areas, and response timeline protects you legally and financially.

What If…? Planning for a Catastrophic Backup During Peak Business Hours

Your worst-case scenario probably involves a complete grease trap failure during your busiest service periods—when closure means losing significant revenue and potentially disappointing customers who’ve made advance reservations.

This scenario represents a major operational challenge because it combines substantial financial impact with complex logistical decisions. But having a specific plan for peak-hour failures reduces both the chaos and the potential losses.

First, acknowledge the reality: A significant backup during peak service may require immediate closure of affected areas, and possibly the entire operation. Attempting to continue service around major contamination usually creates bigger problems.

Second, establish clear decision protocols: Determine in advance who has authority to make closure decisions during peak hours. Waiting for ownership approval while contamination spreads typically escalates both cleanup complexity and regulatory response.

Third, prepare stakeholder communication templates: Draft messages for customers, delivery platforms, and staff that explain temporary closure due to “urgent maintenance requirements.” Having professional language ready prevents crisis-driven communication that could damage your reputation.

The Aftermath: Documentation and Moving Forward

Once the immediate crisis passes and professional cleanup concludes, your focus shifts to compliance documentation and preventing recurrence. This phase often determines whether you face ongoing regulatory attention or return to normal operations smoothly.

The Unasked Question:

What Documentation Do I Need from the Emergency Service to Prove Compliance After the Fact?

Most managers focus entirely on getting their operation running again, overlooking the paperwork that protects them from future regulatory challenges. This documentation becomes important if health inspectors investigate or if insurance questions arise about the incident.

Why This Question Matters

Health departments may investigate grease trap incidents after they occur, especially if there are complaints or if the incident appears in municipal service records. Without proper documentation, you’re left trying to reconstruct events from memory while facing potential regulatory questions.

The Expert Answer

According to the DraneRanger.com framework, essential documentation should include: waste disposal records showing proper handling, before-and-after documentation from the service provider, sanitization verification for affected areas, and a timeline of the incident and response. These documents demonstrate both environmental compliance and that contaminated areas have been properly addressed for food service resumption.

Store these documents with your other compliance files—you may need them if questions arise during future inspections.

Myth & Fact

Myth: Grease trap maintenance is just a suggestion, not a strict legal requirement.

Fact: Houston requires regular grease trap cleaning for commercial food service establishments. Violations can result in significant fines and potential operating complications. Regular maintenance represents required compliance that protects both public health and your business operations.

Expert Q&A

Question: What’s the first thing I should do if my grease trap overflows?

Answer: Stop all food preparation immediately and secure the contaminated area. Your priority isn’t minimizing lost sales—it’s preventing cross-contamination that could result in health department complications. Document the situation with photos, then call certified emergency cleanup services. Attempting to continue service around contaminated areas typically escalates both health concerns and cleanup requirements. — DraneRanger.com Insights Team

Conclusion: From Crisis to Control: Building a Resilient Operation

Emergency preparedness transforms restaurant managers from reactive crisis fighters into proactive risk managers. The five-step protocol outlined above gives you the framework to maintain control when systems fail—but the real value lies in building operational resilience that prevents most emergencies from occurring.

Smart managers recognize that grease trap failures represent just one component of comprehensive liquid waste management. While emergency response plans handle crisis situations, preventative maintenance through regular commercial grease trap cleaning helps eliminate most emergency situations entirely. Regular maintenance typically proves more cost-effective than emergency response over time.

Moving forward, use this emergency framework as your baseline for crisis response, but focus your primary energy on prevention. Regular inspections, adherence to Houston’s maintenance requirements, and staff training on proper grease disposal practices create the foundation for reliable operations.

As you advance in your career toward regional management roles overseeing multiple locations, this crisis management experience becomes invaluable. The ability to implement standardized emergency protocols across multiple restaurants—and train location managers to execute them confidently—represents exactly the kind of operational expertise that franchise owners value most. Today’s crisis management knowledge becomes tomorrow’s regional leadership foundation.

Ready to protect your operation with professional emergency response services? Start Your Service Today – Call 281-489-1765

Our Editorial Process

This guide was drafted with AI assistance and has been reviewed, fact-checked, and edited by the humans experts on our Insights Team to ensure accuracy and clarity.