📌 Key Takeaways

Standard pumping empties the grease trap, while hydro-jetting scours hardened buildup from pipe walls to restore flow capacity.

- Pumping Maintains, Jetting Restores: Standard pumping removes FOG from the trap but cannot reach hardened deposits stuck inside plumbing lines.

- Symptoms Signal Line Restrictions: Recurring slow drains, persistent odors, or backups shortly after pumping indicate buildup that jetting addresses.

- Validate With Specific Questions: Ask which line needs cleaning, what problem jetting solves, and request itemized scope before approving service.

- Frequency Follows FOG Volume: Heavy-frying kitchens often add periodic jetting as preventive maintenance, while lighter operations jet only when symptoms appear.

- Houston’s 25% Rule Triggers Service: Combined floating grease and settled solids exceeding 25% of liquid depth requires immediate cleaning regardless of schedule.

Pumping maintains compliance; jetting fixes what pumping cannot reach.

Houston restaurant operators navigating recurring drainage issues will gain diagnostic clarity here, preparing them for the validation questions that follow.

The vendor hands you a carbon-copy manifest. The job’s done. Then adds: “We recommend hydro-jetting next time.”

You’re left wondering: is this legitimate maintenance or an upsell? When you’re already paying for grease trap cleaning, how do you know if you actually need the more expensive option?

Here’s the practical difference: Standard pumping removes FOG waste from the grease trap but not hardened line buildup. Hydro-jetting scours grease-coated pipes to restore diameter and flow. One maintains the trap; the other restores the entire system.

Pumping empties the tank. Jetting clears the arteries.

This guide gives you a side-by-side comparison, a quick checklist of symptoms, and validation questions so you can approve the right service with confidence.

What Standard Pumping Does (and What It Doesn’t)

Standard pumping is the evacuation service most Houston restaurants schedule quarterly to stay compliant. A vacuum truck removes the accumulated fats, oils, and grease from inside your grease trap or interceptor, along with settled solids at the bottom.

The trap itself serves a critical function: it intercepts FOG before it enters the sewer system. When it fills beyond capacity, problems announce themselves quickly—often at the worst possible moment. Picture this: 10:30 AM in the prep kitchen, a faint sulfur odor rising from the floor drain just before the lunch rush begins. That smell signals your system is approaching failure.

Professional grease trap cleaning involves inserting hoses into the trap’s access points, pumping out the contents, and disposing of the waste at an approved facility. The service creates the manifest documentation required for FOG compliance in Houston.

What pumping doesn’t do: it doesn’t remove hardened buildup that has already attached to the interior walls of your plumbing lines. Once FOG waste hardens inside the pipes—whether connecting the kitchen to the trap or leading away from it—standard pumping can’t reach it. The trap might be empty, but the lines remain partially obstructed.

Think of it this way: pumping cleans the collection point but doesn’t address what’s already stuck in the plumbing.

What Hydro-Jetting Is and Why Vendors Recommend It

Hydro-jetting uses high-pressure water—typically between 3,000 and 4,000 PSI—to scour the interior surfaces of grease lines. The pressurized stream breaks apart calcified grease deposits and flushes them out of the system, restoring the pipe to closer to its original diameter.

Technicians insert a specialized nozzle into the grease line, usually through a cleanout access point. The nozzle sprays water in multiple directions as it travels through the pipe, scouring buildup from the walls. The dislodged material flows back to the trap, where it’s then pumped out.

Common targets for jetting include the lateral lines connecting kitchen drains to the trap, the inlet piping leading into the trap, and the outlet piping carrying filtered water away from it.

This is a restoration service, not routine maintenance. Vendors recommend it when they observe restricted flow, when you’re experiencing recurring symptoms despite regular pumping, or when a camera inspection reveals significant buildup inside the lines.

Pumping vs. Hydro-Jetting: Side-by-Side Comparison

| Service Aspect | Standard Pumping | Hydro-Jetting |

| Purpose | Evacuate FOG and solids from the trap | Scour hardened buildup from pipe walls |

| Best For | Routine compliance and prevention | Restoring flow when lines are restricted |

| Typical Frequency | At least every 90 days (Houston minimum), or sooner if the 25% rule is reached | As needed based on symptoms; possibly annual for high-FOG kitchens |

| Disruption/Time | 30-60 minutes, minimal kitchen impact | 1-3 hours depending on scope; some drain access needed |

| Relative Cost | Standard service rate | Higher due to equipment, labor, and scope |

| Outcome | Empty trap, compliance documentation | Restored pipe diameter and improved drainage |

The cost difference reflects the additional scope. Jetting typically runs higher than pumping because it involves specialized equipment and more time on task. Cost drivers include the length of line being cleaned, the severity of buildup, access complexity, and whether the work targets one segment or requires multiple runs through different sections.

Note that Houston regulations (Chapter 47, Article XI, Section 47-741) require grease trap cleaning whenever the combined depth of floating grease and settled solids exceeds 25% of the total liquid depth in the trap, even if this occurs before the 90-day interval. High-volume kitchens may reach this threshold sooner and need more frequent service.

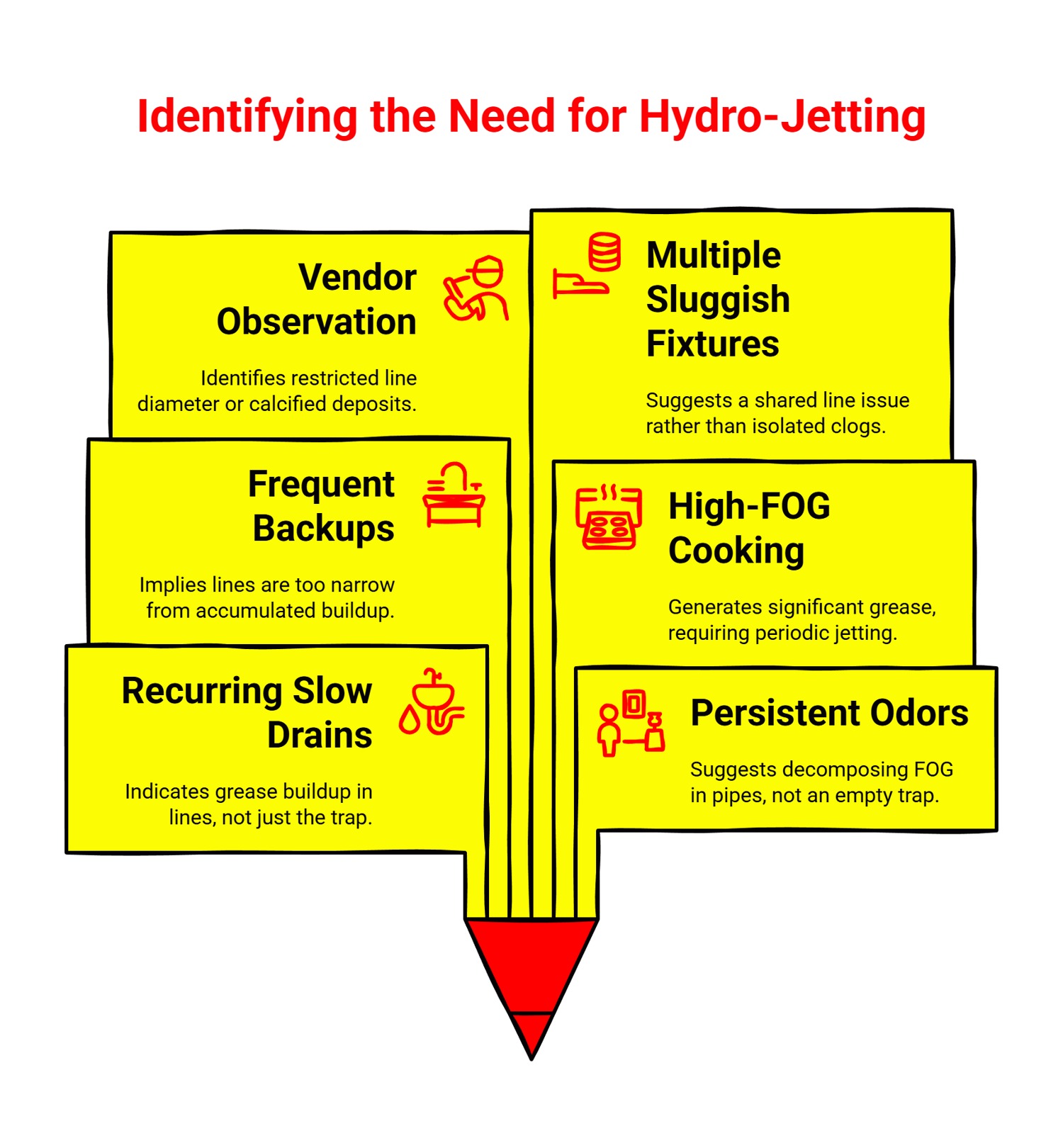

Signs You Likely Need Hydro-Jetting

Not every restaurant needs jetting, but recurring slow drains and odors indicate buildup in grease lines that pumping alone may not fix. Watch for these specific symptoms:

- Recurring slow drains even after recent pumping. If sinks are draining sluggishly within days or weeks of a pump-out, the obstruction is likely in the lines, not in the trap itself.

- Persistent odors returning quickly. When foul smells reappear shortly after cleaning, grease buildup in the lines is often the culprit. The trap is empty, but decomposing FOG remains stuck in the pipes.

- Backups between scheduled cleanings. If you’re experiencing overflows or backups before the 90-day mark, your system can’t handle your current FOG load. This often means the lines are too narrow from accumulated buildup.

- High-FOG cooking profile and heavy volume. Operations running fryers, cooking burgers, or serving fried chicken generate significant grease. High-FOG, high-volume kitchens benefit from periodic jetting to prevent backups between cleanings.

- Vendor observation of hardened or calcified grease. If your service technician reports seeing restricted line diameter or calcified deposits during inspection, they’re identifying a problem pumping can’t solve.

- Multiple fixtures draining sluggishly. When several sinks or drains show slow flow simultaneously, it suggests a shared line issue rather than isolated clogs.

These aren’t guarantees you need jetting, but they’re legitimate triggers for the conversation. For additional diagnostic perspective, see five signs your grease trap service isn’t doing the job right. Compare the symptom severity to your service history before approving the work.

When Standard Pumping Is Usually Enough

Many Houston restaurants operate successfully with pumping alone. If you’re not experiencing symptoms and your schedule is consistent, you’re likely in good shape.

Standard pumping is usually sufficient when FOG volumes are moderate, the trap is staying within acceptable thresholds, and you’re primarily focused on maintaining compliance and preventing emergencies rather than addressing active problems.

Restaurants with lower grease output—those without heavy frying operations—often maintain clear lines with quarterly pumping and good kitchen practices like scraping plates and using drain screens.

Houston vs. Suburban MUDs, and Indoor vs. Outdoor Traps: Two Pivots That Change the Decision

Two decision variables affect how you evaluate service recommendations.

Pivot 1: City of Houston vs. Suburban MUD Jurisdictions

Houston enforcement tends to be stricter than some suburban Municipal Utility District contexts, with particular emphasis on manifest documentation rather than invoice-only recordkeeping. For official city information, reference the City of Houston official site.

The practical implication: when operating within stricter jurisdictions, documentation becomes risk control—more like insurance than admin. That tactile crinkle of the carbon-copy manifest paper being handed over by the driver isn’t just proof of service; it’s a chain-of-custody artifact that can reduce audit anxiety.

Pivot 2: Indoor Hydro-Mechanical vs. Outdoor Gravity Interceptors

Trap type affects frequency and disruption patterns. Indoor hydro-mechanical traps are typically smaller and can reach problematic conditions faster under heavy grease load. Outdoor gravity interceptors are typically larger and may tolerate volume differently, but when line restrictions occur, the disruption can still be significant.

Practical takeaway: smaller indoor units and heavy-volume kitchens often experience earlier symptom-based escalation. That doesn’t automatically mean “jet every visit.” It means symptom tracking matters more, and restoration work should be tied to evidence of restricted flow.

How to Validate a Jetting Recommendation (and Avoid Unnecessary Upsells)

When a vendor recommends jetting, you have every right to ask clarifying questions. Legitimate service providers expect this and will give you specific answers.

Ask what problem jetting is solving. Request the specific symptom (slow drains, odors, backups) and the location (which line is restricted). Vague recommendations like “it’s due” or “it’s good preventive maintenance” aren’t sufficient justification for the added expense.

Ask for a before-and-after description. A professional technician should be able to explain what they expect to find and what the result should look like. Some companies use camera inspections to show the buildup before jetting and verify the results after. If camera evidence is available, request to see it.

Confirm the scope of work. Get clarity on which lines will be jetted, how far the technician will run the equipment, expected duration, and the cleanup plan. An itemized quote should specify these details.

Compare the recommendation to your symptom severity and service history. If you’ve had no drainage issues and your last three cleanings went smoothly, aggressive jetting recommendations deserve scrutiny. Conversely, if you’ve had two backups in six months, jetting is likely warranted.

For complex situations or if you’re uncertain, consider getting a second opinion from another qualified service provider in the Houston area. A legitimate company focused on commercial grease trap maintenance will base recommendations on observable conditions, not sales targets.

Hydro-Jetting vs. a Drain Snake: What’s the Difference?

A common comparison question involves the difference between hydro-jetting and using a drain snake or auger.

A snake or auger is designed to mechanically pierce or retrieve a localized blockage—essentially punching a hole to restore immediate drainage. Hydro-jetting uses scouring pressure to emulsify and flush buildup from the pipe walls, addressing widespread grease coating that narrows the entire line diameter.

Practical takeaway: if symptoms are recurring and “cleared” only temporarily with snaking, jetting may be proposed because it targets the underlying buildup rather than only breaking through a single point of resistance.

How Often Do Restaurants Need Jetting?

There’s no universal answer because it depends entirely on your FOG volume and symptom history. Heavy-volume kitchens with significant frying operations often add jetting to their annual maintenance plan as preventive care, while lighter-volume operations may go years between jetting services.

The tipping point is symptom-driven. When slow drains, persistent odors, or backups appear despite regular pumping, you’ve moved from “compliance minimum” to “failure prevention” territory. At that stage, jetting becomes necessary to restore system capacity.

Some operations implement annual or semi-annual jetting as standard practice once they understand their usage patterns. Others jet only when symptoms appear. Both approaches can be valid depending on your kitchen’s specific profile and risk tolerance.

Visualizing the Difference: Before and After Jetting

Understanding what jetting accomplishes is easier when you visualize the pipe interior.

Before jetting: Water flows through a narrowed “ring” where grease buildup has coated the pipe walls, leaving only a small center channel for drainage. The trap may be freshly pumped, but flow remains restricted.

After jetting: Water flows through a wider, cleaner interior diameter. The high-pressure water has scoured away the coating, restoring the line closer to its original capacity.

The exact appearance varies by pipe material, grease load, and how long buildup has been accumulating, but the principle remains: jetting restores the space that hardened grease has stolen from the system.

Frequently Asked Questions

What is hydro-jetting?

Hydro-jetting is a cleaning method that uses high-pressure water (typically 3,000-4,000 PSI) to scour grease and buildup from inside pipes, restoring flow.

Does pumping clean the pipes?

Pumping removes waste from the trap, but it typically does not remove hardened buildup inside plumbing lines. When symptoms persist after pumping, line restoration may be needed.

How do I know if I’m being upsold on jetting?

Ask what symptom jetting solves, what line will be cleaned, and request an itemized scope with a clear before/after explanation. Legitimate recommendations tie the service to observable problems.

How often should a restaurant hydro-jet?

It depends on grease volume and symptoms. Heavy-FOG kitchens often add periodic jetting as preventive maintenance; lighter kitchens may need it less frequently. Let symptoms guide the decision.

Next Steps: Choose the Right Service Level and Keep Compliance Invisible

The decision comes down to current symptoms and operational priorities. Use this simple flow:

- No symptoms, regular schedule working well → Continue with standard quarterly pumping

- Occasional slow drains or mild odors → Monitor closely; consider scheduling jetting if symptoms worsen

- Recurring problems after pump-outs → Schedule jetting to restore line capacity

- High-FOG kitchen with frequent issues → Implement periodic jetting as preventive maintenance

The goal is invisible compliance—systems that work so reliably you never think about them during service. Whether that requires pumping alone or periodic jetting depends on your specific operation, but you now have the criteria to make an informed decision.

For service in the Houston area, explore our grease trap cleaning services or contact us to schedule service. If you’re experiencing urgent symptoms like backups or persistent drainage issues, our emergency services team can respond quickly to restore your system.

For additional trust and credibility verification, review our Better Business Bureau profile.

Disclaimer: This article is for informational purposes and should not replace professional advice. Grease trap maintenance requirements can vary based on local regulations, facility type, and operational factors. Always consult with qualified service professionals for recommendations specific to your situation.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.