📌 Key Takeaways

Houston’s grease trap compliance hinges on one measurable threshold: when floating grease plus settled solids reach 25% of your trap’s liquid depth, schedule service immediately—regardless of the calendar.

- Core Sampling Reveals What Visual Checks Miss: Bottom sludge accumulates invisibly beneath a seemingly clean surface, making core sampling through the sample well the only reliable measurement method inspectors accept.

- The 25% Rule Overrides the 90-Day Clock: High-volume kitchens often hit the 25% threshold in six to eight weeks, triggering mandatory service even when the quarterly deadline hasn’t arrived—compliance follows accumulation, not the calendar.

- Manifests Prove Legal Disposal, Not Just Payment: A signed waste manifest creates a chain-of-custody record that protects restaurants from liability if haulers dump illegally, making it the critical compliance document inspectors require.

- Measurement Drives Predictable Scheduling: Taking core samples every two to three weeks reveals each kitchen’s actual accumulation rate, enabling operators to pre-book service before hitting the 25% trigger rather than reacting to odors or backups.

- The Three-Step Compliance Loop Prevents Violations: Measure with core sampling, schedule proactively based on trend data, and maintain organized manifests—this systematic approach keeps Houston restaurant kitchens audit-ready and operations running smoothly.

Measure before you’re mandated, schedule before you’re late, document before you’re inspected.

Houston restaurant owners, general managers, and facilities managers will find this framework here, preparing them for the detailed measurement and scheduling guidance that follows.

The 25% rule defines when Houston restaurants must clean their grease traps: when the combined depth of floating grease and settled solids reaches approximately one-quarter of the trap’s total liquid depth. Think of it like an oil-change indicator—hit the line, you service now.

Picture this scenario. It’s Friday lunch rush, and a city inspector walks into your kitchen. They ask to see your most recent core sample reading. You check your log. The measurement shows 28%.

That simple number tells the inspector everything they need to know—and it determines whether you’re compliant or facing a violation. Schedule your pump-out before reaching 25% or by the quarterly mandate, whichever comes first.

What is Houston’s 25% Rule?

What is the 25% rule for grease traps?

The 25% rule is the operational threshold that triggers mandatory grease trap cleaning in Houston. It measures total accumulation—both the floating grease cap at the top of your trap and the settled solids at the bottom—as a percentage of the trap’s liquid depth.¹

When these two layers combined equal roughly one-quarter of the total depth, the trap has reached its functional limit. At this point, the trap can no longer effectively separate fats, oils, and grease (FOG) from wastewater.

This isn’t an arbitrary number. The 25% threshold represents the point where trap efficiency degrades significantly, increasing the risk of FOG entering the municipal sewer system.¹ City ordinances in Houston recognize this as the functional compliance trigger, meaning you must schedule service when you hit or exceed this accumulation level.

Treat 25% as your “service-now” line. Waiting until you’re well past this threshold—or worse, waiting until you smell problems—puts your business at risk of violations, backups, and costly emergency service calls.

25% vs. 90 Days—Which Comes First?

Houston restaurants face two overlapping requirements: the 25% accumulation threshold and the quarterly (90-day) cleaning mandate. You must clean at whichever trigger comes first.¹

For many operations, especially high-volume kitchens, the 25% threshold arrives well before 90 days have elapsed. A busy restaurant producing significant grease loads might hit 25% in just six to eight weeks. When this happens, the clock doesn’t matter—the accumulation level takes priority.

The quarterly mandate serves as a backstop. Even if your trap measures below 25% at the three-month mark, city regulations for traps within Houston limits still require cleaning.¹ This ensures that lower-volume operations maintain regular service intervals and proper trap function.

Understanding which trigger applies to your specific operation requires measurement and tracking. High-volume kitchens need shorter service intervals; lower-volume operations may run closer to the quarterly schedule. The key is measuring regularly to know where you stand and adjusting your maintenance calendar accordingly.

How Inspectors Measure It (and How You Should Too)

How do inspectors measure the 25% rule—do visual checks count?

Inspectors don’t rely on visual surface checks. They use core sampling through your trap’s sample well to get an accurate cross-section of all three layers: the grease cap, the clear water zone, and the settled solids at the bottom.

A visual check from the top only shows you the grease cap—and even that measurement is unreliable without proper tools. The real problem lies beneath the surface. Settled solids accumulate at the trap bottom, invisible to anyone just lifting the lid for a quick look. These solids count toward your 25% total, and inspectors know that surface appearances miss this critical layer. Visual checks alone cannot prevent the sewer blockages and overflows that FOG regulations are designed to stop.

Core sampling provides a complete vertical profile. The sampler—commonly called a sludge judge—captures material from top to bottom in a single pull. This allows for precise measurement of both the floating grease thickness and the depth of bottom sludge.

Your measurement protocol should match the inspector’s method. Use a core sampler designed for grease traps, accessed through your trap’s sample well. Record the top grease layer thickness, the clear water zone depth, and the bottom solids depth. Calculate these measurements against your trap’s total liquid depth to determine your accumulation percentage.

Visual checks fail inspections. Core sampling passes them. Make the investment in the right tool and the right technique.

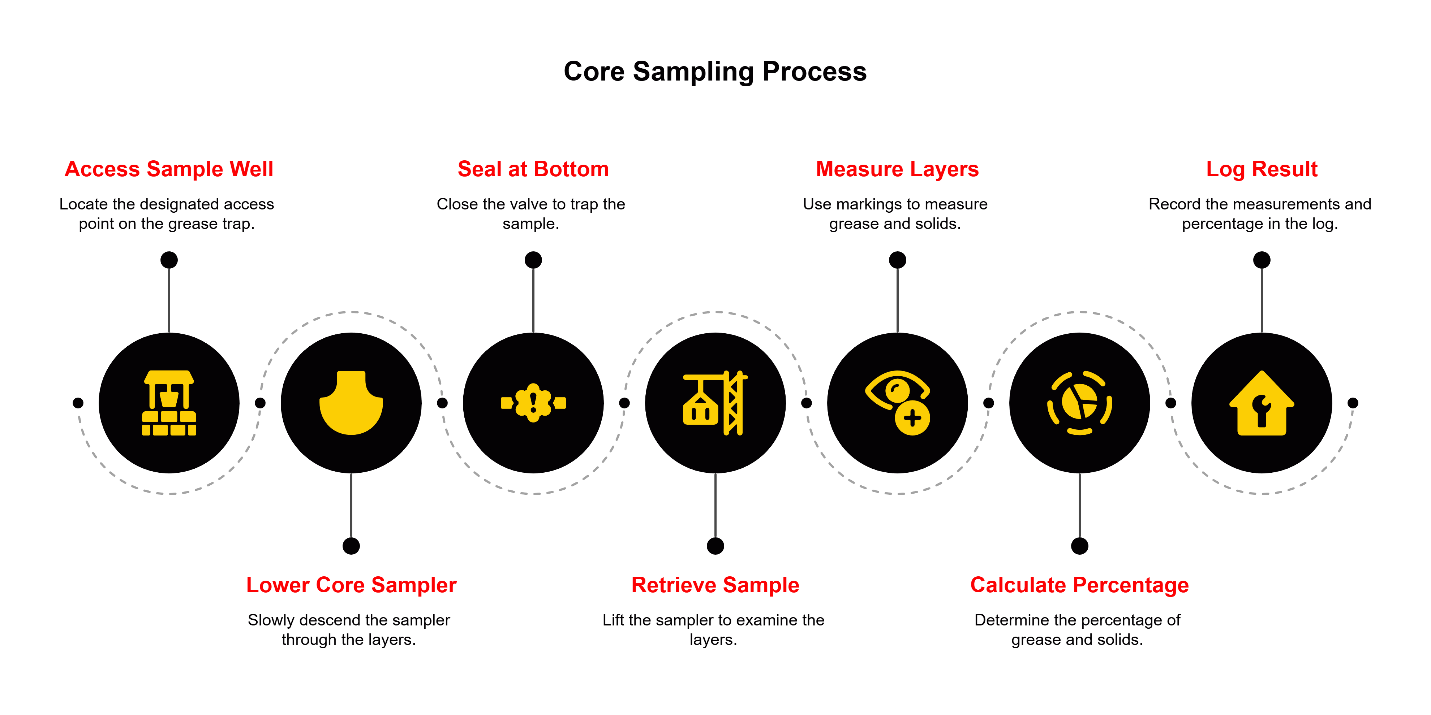

Step-by-Step: Take a Core Sample in 5 Minutes

Does floating grease count toward the 25% rule?

Yes. Both floating grease and settled solids count toward your 25% total.¹ Here’s how to measure both layers accurately:

Access your sample well. Most grease traps have a dedicated sample well or measurement port. Locate this access point—it’s typically marked and provides a clear vertical path to the trap bottom.

Lower your core sampler slowly. A sludge judge or similar core sampling tool should descend through all three layers without disturbing them. Keep the bottom valve closed during descent to prevent water from entering the tube prematurely.

Reach the trap bottom, then seal. When you feel the sampler touch bottom, close the bottom valve to trap the vertical sample inside the tube. This captures a complete cross-section from top to bottom.

Retrieve and read the layers. Lift the sampler straight up and examine the captured sample. You’ll see three distinct zones: grease at the top (often yellowish or tan), clear water in the middle, and dark settled solids at the bottom.

Measure and calculate. Use the graduated markings on your sampler to measure:

- Top grease layer depth

- Bottom solids layer depth

- Total liquid depth (grease + clear water + solids)

Add the grease and solids measurements, then divide by total depth and multiply by 100 for your percentage. If grease is 2 inches, solids are 3 inches, and total depth is 20 inches: (2 + 3) ÷ 20 = 0.25, or 25%.

Log the result immediately. Record the date, time, all three measurements, and the calculated percentage in your maintenance log. This documentation proves you’re monitoring compliance between service visits.

Assign this task to a designated kitchen manager or facilities lead. Taking a reading once every two to three weeks gives you advance warning before you hit the 25% threshold.

Scheduling Logic: Turn Readings into a Maintenance Calendar

Raw measurements mean nothing without a maintenance plan. Use your readings to establish a service cadence that prevents you from ever reaching the 25% trigger unexpectedly.

Start with a 90-day baseline if you’re new to systematic tracking. Schedule your first professional cleaning, then begin taking core samples every two weeks. Track the accumulation rate over the first three months. This data reveals how quickly your specific operation approaches the 25% threshold.

High-volume kitchens often discover they need service every six to eight weeks. Lower-volume operations might find they run comfortably at 75 or 85 days. The measurement trend tells you what your kitchen actually needs—not what a generic schedule suggests.

Once you know your accumulation rate, schedule the next service appointment before you project hitting 25%. Build in a safety margin. If your readings suggest you’ll reach 25% at week 10, book service for week 8 or 9. This buffer accounts for unexpected volume spikes during busy seasons or special events.

Pre-booking service creates schedule certainty. This quiet protection—operating like an invisible shield between your kitchen and expensive sewer problems—means you avoid last-minute emergency calls, and your service provider can plan routes more efficiently. Many operators find that turning measurements into a reliable schedule reduces both stress and cost over time.

Compliance Paperwork: The Manifest Is Your Proof

Cleaning your grease trap removes the waste. The manifest proves you disposed of it legally.

A waste manifest is a legal tracking document that follows your grease trap waste from your property to its final disposal site. It identifies the waste generator—your restaurant—along with the hauler, the transport vehicle, and the receiving facility.¹ All parties sign the manifest, creating a chain-of-custody record.

For Houston restaurant operators, this document serves two critical functions. First, it demonstrates compliance with city FOG (fats, oils, and grease) ordinances that require proper waste disposal. Second, it protects you if there’s ever a question about where your waste ended up. If a hauler dumps illegally, the signed manifest proves you fulfilled your legal responsibility by hiring a registered service provider.

After every pump-out, file the signed manifest in a dedicated Compliance Binder. Organize manifests chronologically with the most recent on top. Keep this binder readily accessible for inspector visits. Regulatory guidance recommends retaining manifests for at least five years to cover typical audit windows.¹

Missing manifests raise red flags during inspections. An inspector sees a clean trap but no paperwork trail and must assume non-compliance. That gap can trigger fines even if you’ve been cleaning on schedule. The cleaning proves operational maintenance; the manifest proves legal compliance.

“Organized, professional and on time… suggested time of cleaning again,” one Houston-area operator noted after establishing a consistent manifesting routine with a reliable service provider. That level of systematic documentation turns a potential compliance vulnerability into a strength.

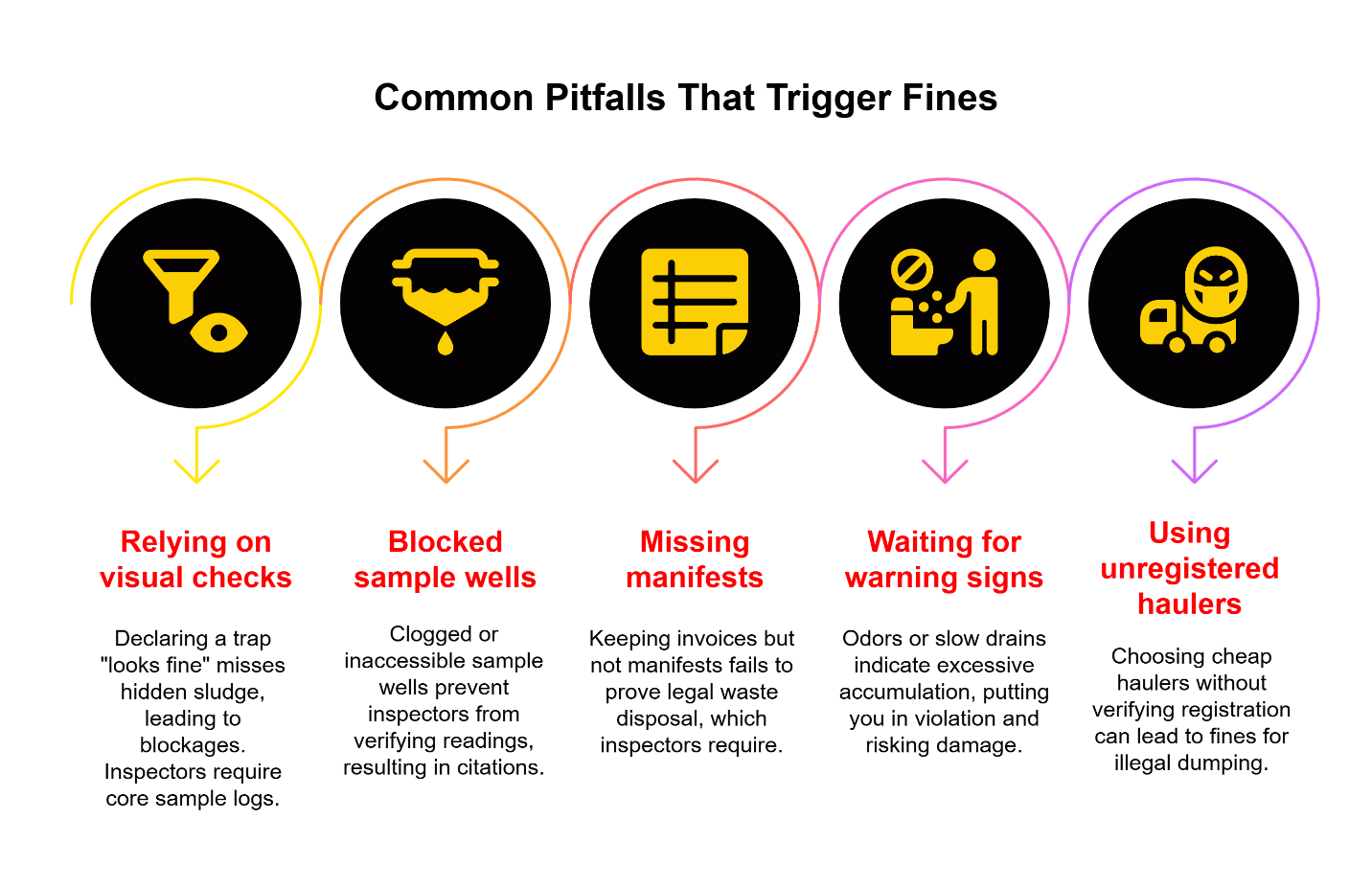

Common Pitfalls That Trigger Fines

Relying on visual checks only. Walking past the trap, lifting the lid, and declaring it “looks fine” misses the bottom sludge layer completely. This hidden accumulation contributes directly to the sewer blockages and sanitary sewer overflows (SSOs) that FOG regulations aim to prevent. Inspectors know this. They’ll ask for your core sample log, and if you don’t have one, the visual assessment means nothing.

Blocked or inaccessible sample wells. Sample wells can become clogged with grease or covered by equipment over time. If an inspector can’t access your sample well to verify your readings, they may cite you for non-compliance regardless of when you last cleaned the trap.

Missing or incomplete manifests. Some operators keep invoices but not manifests, not realizing these are different documents. An invoice shows you paid for a service; a manifest proves legal waste disposal.¹ Inspectors require manifests.

Waiting for warning signs. Bad odors, slow drains, or visible backups mean you’re well past 25%—possibly at 40% or 50% accumulation. By the time you smell a problem, you’re already in violation and facing potential backup damage.

Using unregistered or non-compliant haulers. Some operators choose the cheapest service without verifying the hauler is properly registered and insured. When these haulers skip manifesting or dump illegally, you can still be on the hook as the generator—the legal term for the restaurant that produced the waste.¹ As one satisfied customer shared: “Drain Ranger is very professional and reliable. Basically they can take care of all your grease drain needs.” That reliability includes proper manifesting and disposal—protections worth far more than the small premium over cut-rate alternatives.

These pitfalls share a common thread: reactive rather than proactive management. Houston’s 25% rule exists to prevent problems, not document them after they occur. Everything else is noise.

Frequently Asked Questions

What exactly counts toward the 25%?

Both floating grease and settled solids count toward total accumulation. The clear water zone in the middle does not count—only the material at the top and bottom of the trap.¹

Do I pump at 25% or every 90 days?

You must clean at whichever trigger comes first. If you reach 25% accumulation at week 7, you clean at week 7. If you’re still below 25% at day 90, the quarterly mandate requires service anyway.¹

How do I measure it?

Use a core sampler (sludge judge) accessed through your trap’s sample well. The sampler captures a vertical cross-section showing all three layers. Measure the grease cap depth, the bottom solids depth, and the total liquid depth, then calculate the percentage.

Is a clean-looking surface OK?

No. Surface appearance reveals nothing about bottom sludge accumulation. Inspectors require core sampling data, not visual assessments, because visual checks consistently underestimate total accumulation and cannot prevent sewer blockages.

What paperwork do I keep?

Keep signed waste manifests from every pump-out. Organize them chronologically in a dedicated compliance binder. Maintain these records for at least five years for audit readiness.

Measure, Don’t Guess: Book Before You Hit 25%

The 25% rule transforms grease trap maintenance from guesswork into a measurable process. Floating grease plus settled solids equal your total accumulation. When that total reaches one-quarter of your trap’s liquid depth, schedule service immediately.¹

Core sampling through your sample well provides the accurate measurement inspectors require. Visual checks miss the bottom layer where significant solids accumulate. Take readings every two to three weeks, log the results, and track your accumulation trend over time.

This measurement-based approach reveals your kitchen’s actual service interval—whether that’s every six weeks for high-volume operations or closer to the 90-day maximum for lower-volume establishments. Use this data to pre-book maintenance appointments before you hit the threshold, not after.

The documentation loop completes the compliance picture. Measurement identifies when to clean. Professional service removes the waste. A signed manifest proves legal disposal.¹ Together, these three elements—measure, schedule, manifest—create an audit-ready compliance system that protects your business.

“He has done all my septic work and is the best!” one long-term customer shared. That expertise extends to helping Houston restaurant operators establish systematic maintenance programs built on measurement data, not reactive crisis management.

Understanding what to expect from a professional grease trap cleaning helps operators recognize quality service. Avoiding common FOG violation myths prevents costly mistakes that trigger fines despite good intentions.

The math is simple: measure regularly, schedule proactively, and maintain complete documentation. That systematic approach keeps Houston restaurant kitchens compliant, inspectors satisfied, and operations running smoothly.

Call Drane Ranger to set your maintenance schedule and establish a measurement-based compliance program tailored to your kitchen’s actual service needs, or contact us to request a 25% reading and service quote.

References

- Texas Commission on Environmental Quality (TCEQ). FOG control and interceptor maintenance guidance. Sample ordinance provisions covering 25% accumulation standards, quarterly cleaning requirements, and recordkeeping expectations for waste generators.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.