📌 Key Takeaways

Missing a scheduled pump-out turns a $400 maintenance task into a $20,000 drain field replacement.

- The Two-Layer System Explained: Your septic tank relies on floating scum, settling sludge, and a clear middle zone—when sludge exceeds one-third of tank depth, solids escape to your drain field and cause irreversible damage.

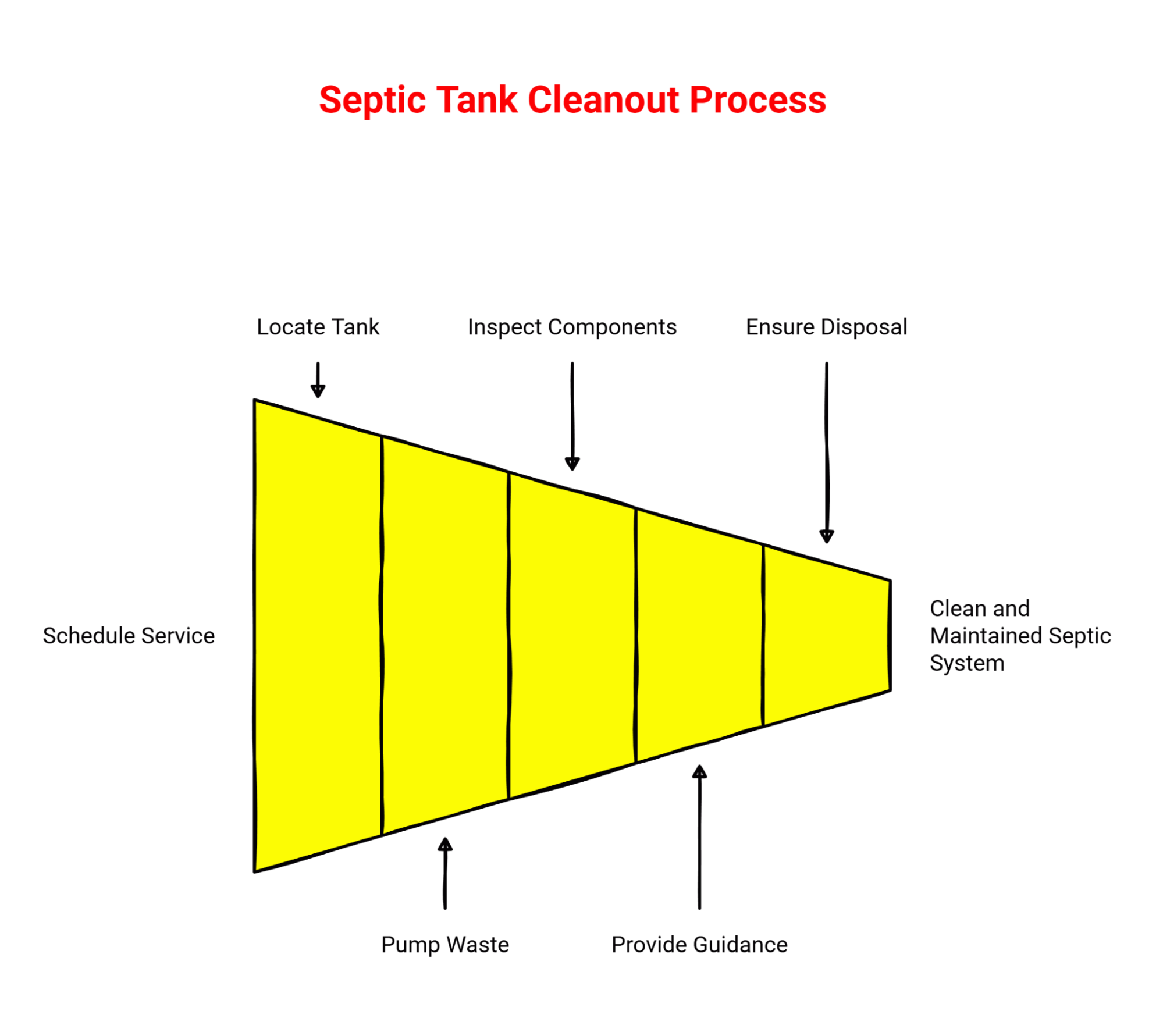

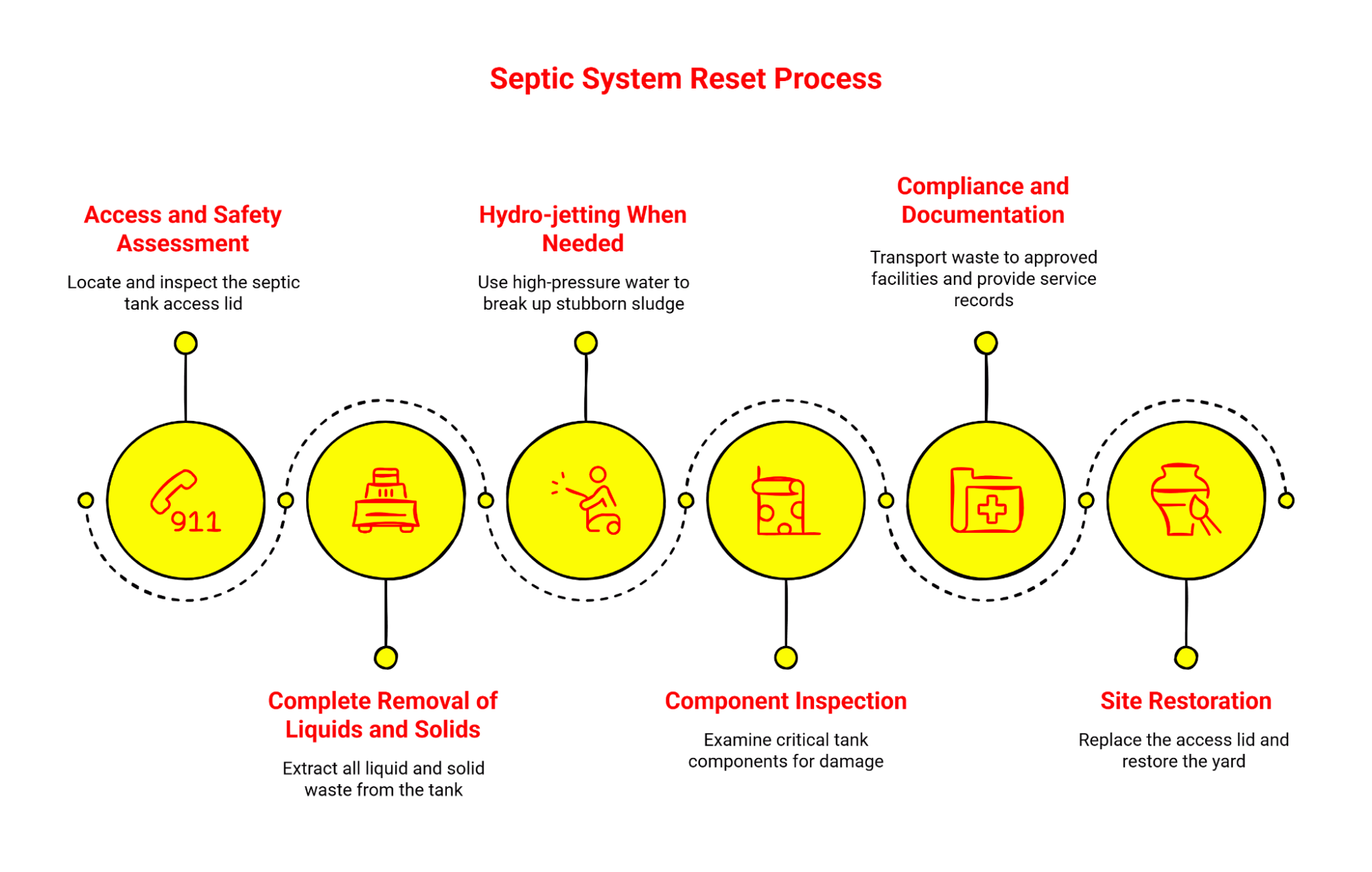

- The Seven-Step Reset Process: Professional service includes arrival prep, lid removal and inspection, complete vacuum extraction, hydro-jetting to remove compacted buildup, component checks for cracks or clogs, compliant waste disposal, and a documented maintenance plan for your next cycle.

- Frequency Follows Household Math: A four-person home with a 1,000-gallon tank needs pumping every 2–3 years, but adding two more people or heavy garbage disposal use cuts that timeline in half.

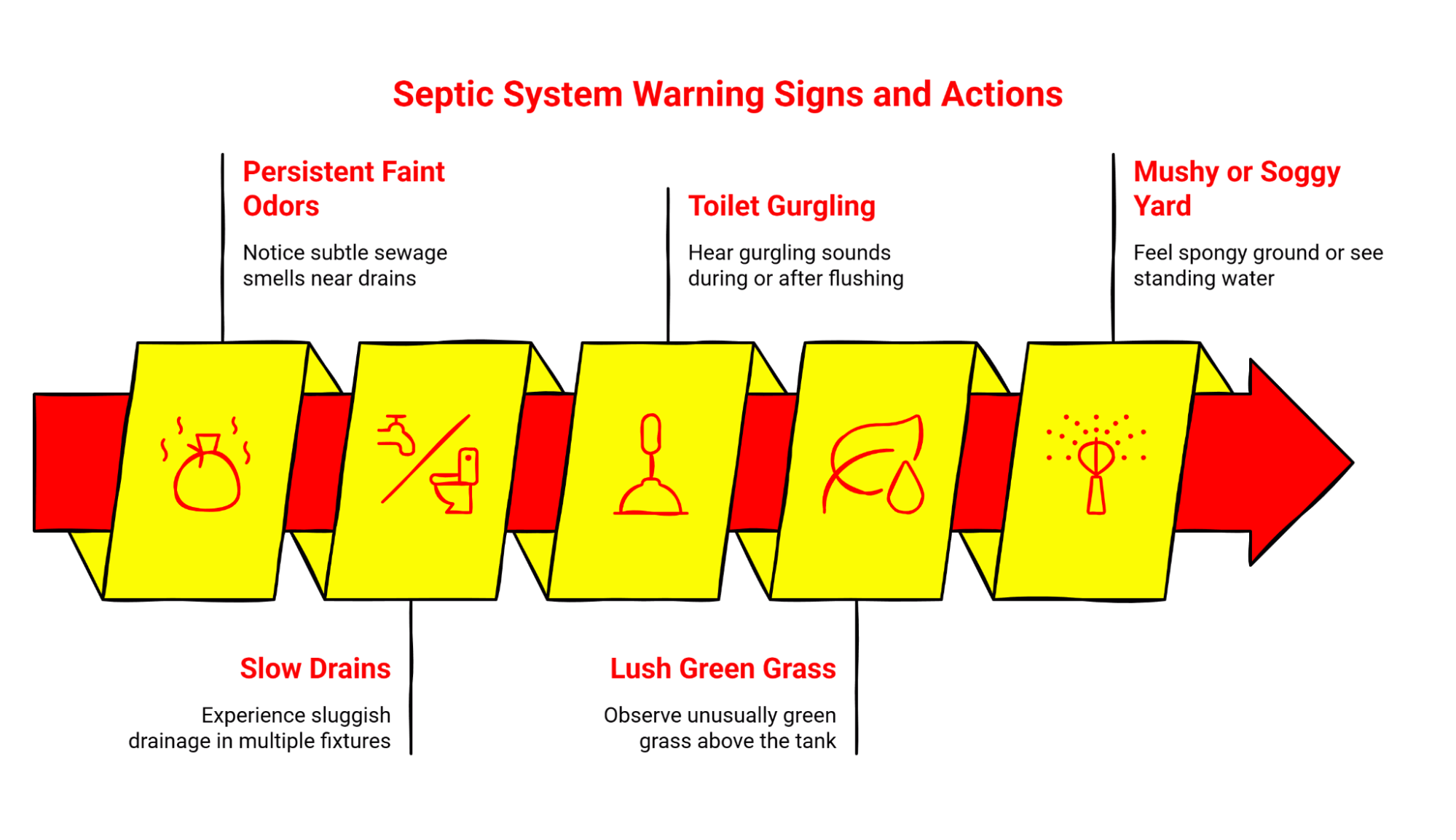

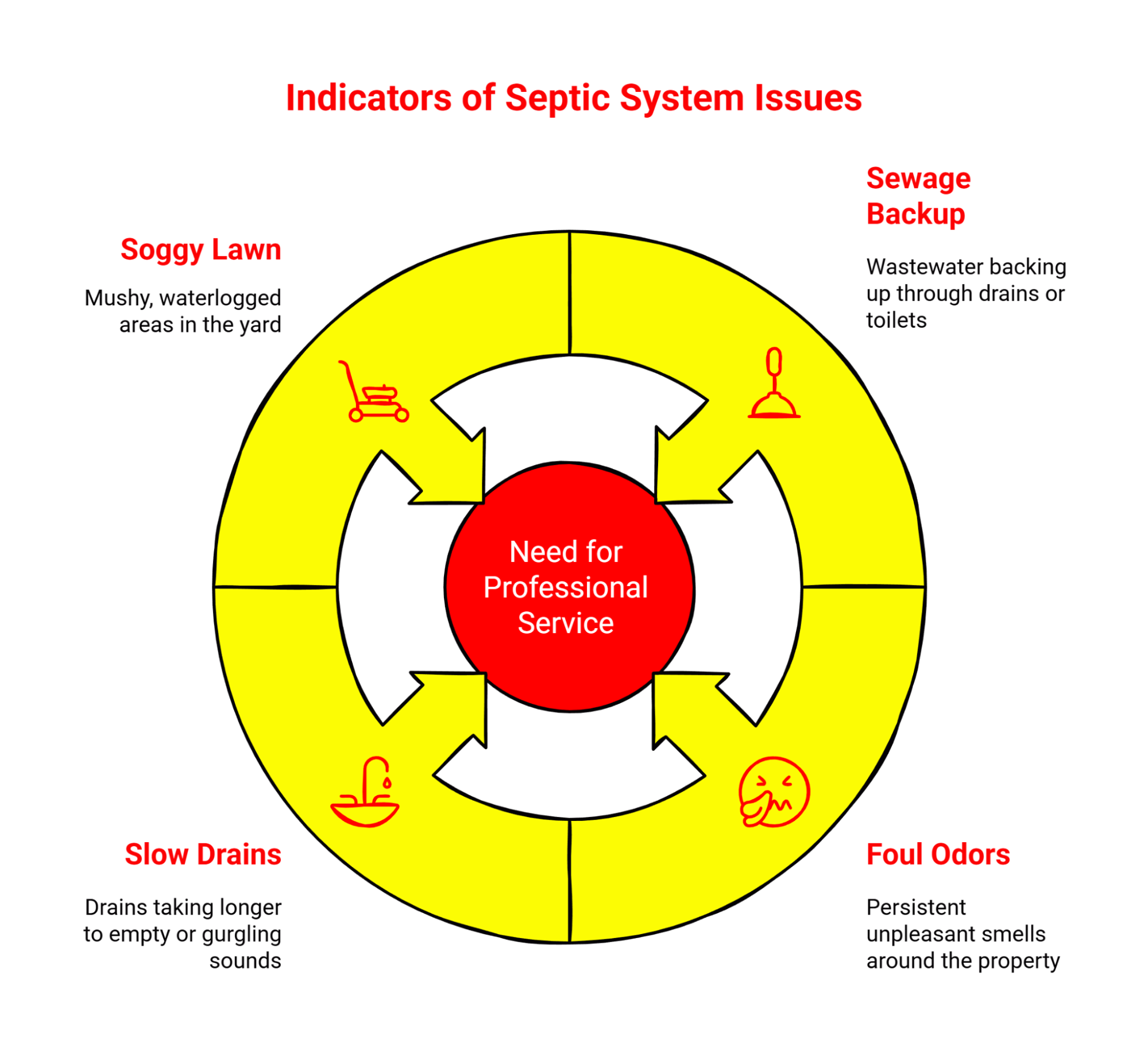

- Early Warning Signs Override Schedules: Sewage odors outside, slow drains, gurgling toilets, or standing water near your tank location signal an urgent need for service—waiting turns fixable problems into emergency repairs.

- Government Standards Protect Community Health: The EPA, Texas Commission on Environmental Quality, and CDC all emphasize that proper septic maintenance prevents groundwater contamination and protects public health beyond your property line.

Regular maintenance preserves system lifespan and prevents catastrophic failure.

Greater Houston homeowners managing septic systems will find clear guidance here, preparing them for the detailed step-by-step walkthrough that follows.

Your septic system works quietly beneath your property, handling waste day after day without complaint. But like any hardworking system, it needs regular maintenance to keep functioning properly. If you’ve never scheduled a pump-out before, the process might seem mysterious or even intimidating.

A septic pump-out starts by exposing and inspecting the tank, then vacuuming all liquids and sludge with a professional vacuum truck. Technicians break up compacted solids, clean interior surfaces (often with hydro-jetting), check baffles and tees, reseal the lids, and dispose of waste responsibly—leaving the system reset and ready.

Residential Septic Tank Cleaning is the professional removal of solid waste and wastewater to restore system capacity. Think of it like an oil change for your home’s plumbing—skip it and the engine seizes. Imagine flushing with total confidence and zero yard surprises. The solution is straightforward: schedule service every 2–3 years to prevent system failure.

Here’s what actually happens when a professional crew arrives at your home, from the moment the truck pulls up to the final inspection and recommendations. Understanding the process helps you know what to expect, why each step matters, and how to choose a provider you can trust.

Why Septic Pump-Outs Matter

Your septic tank separates solid waste from liquids through a natural settling process. Heavier solids sink to form a sludge layer at the bottom, while lighter materials like oils and fats float to create a scum layer on top. The relatively clear liquid in between flows out to your drain field for final treatment.

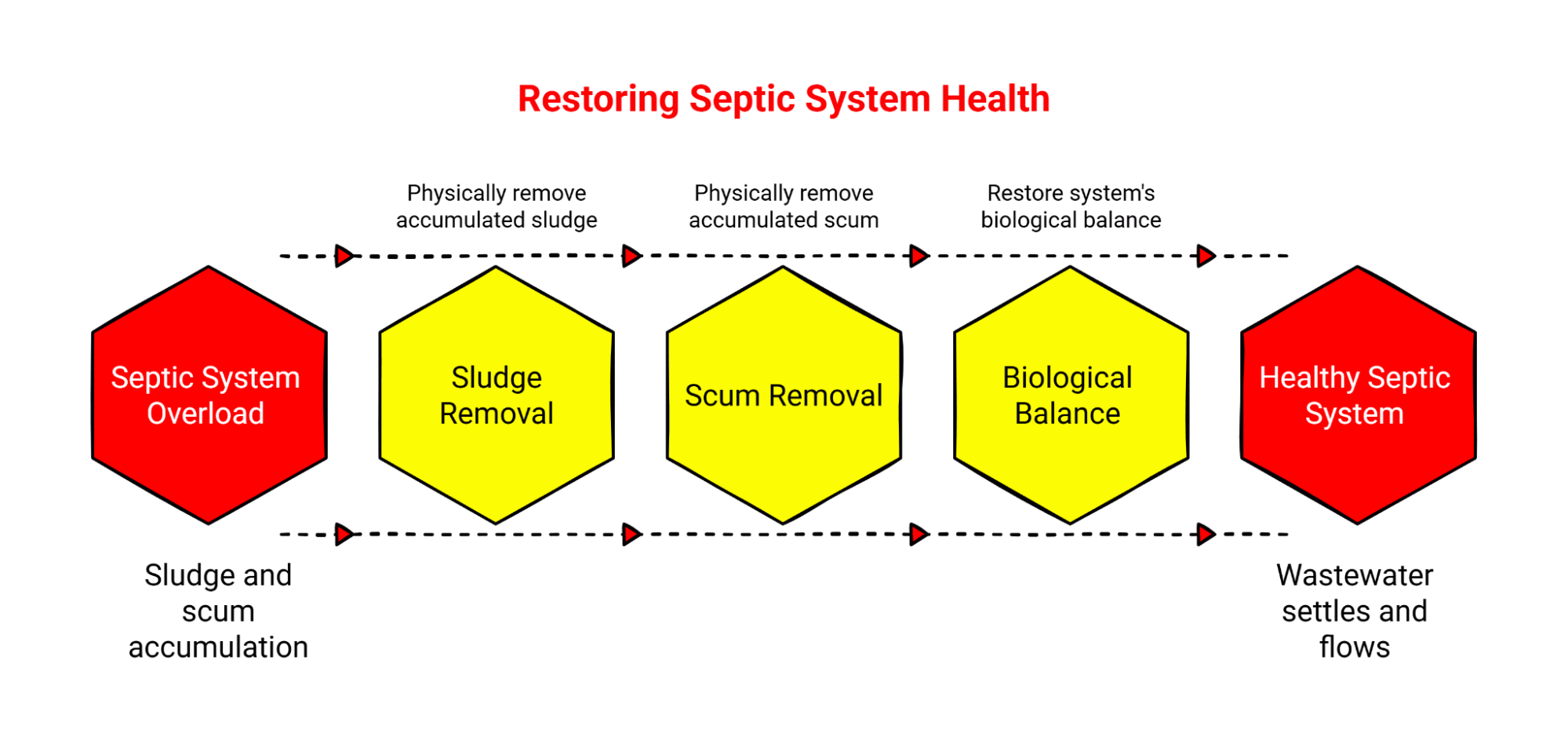

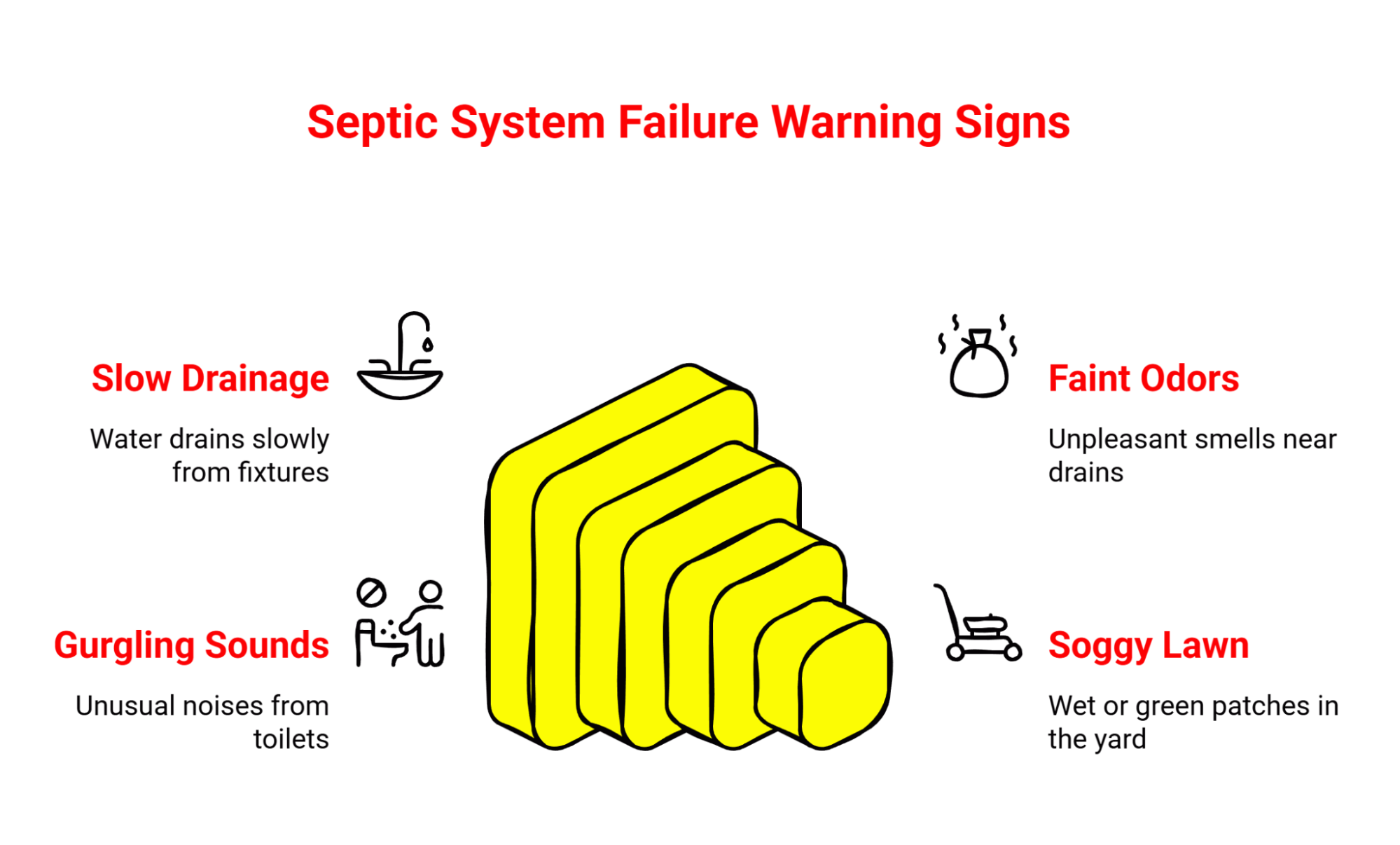

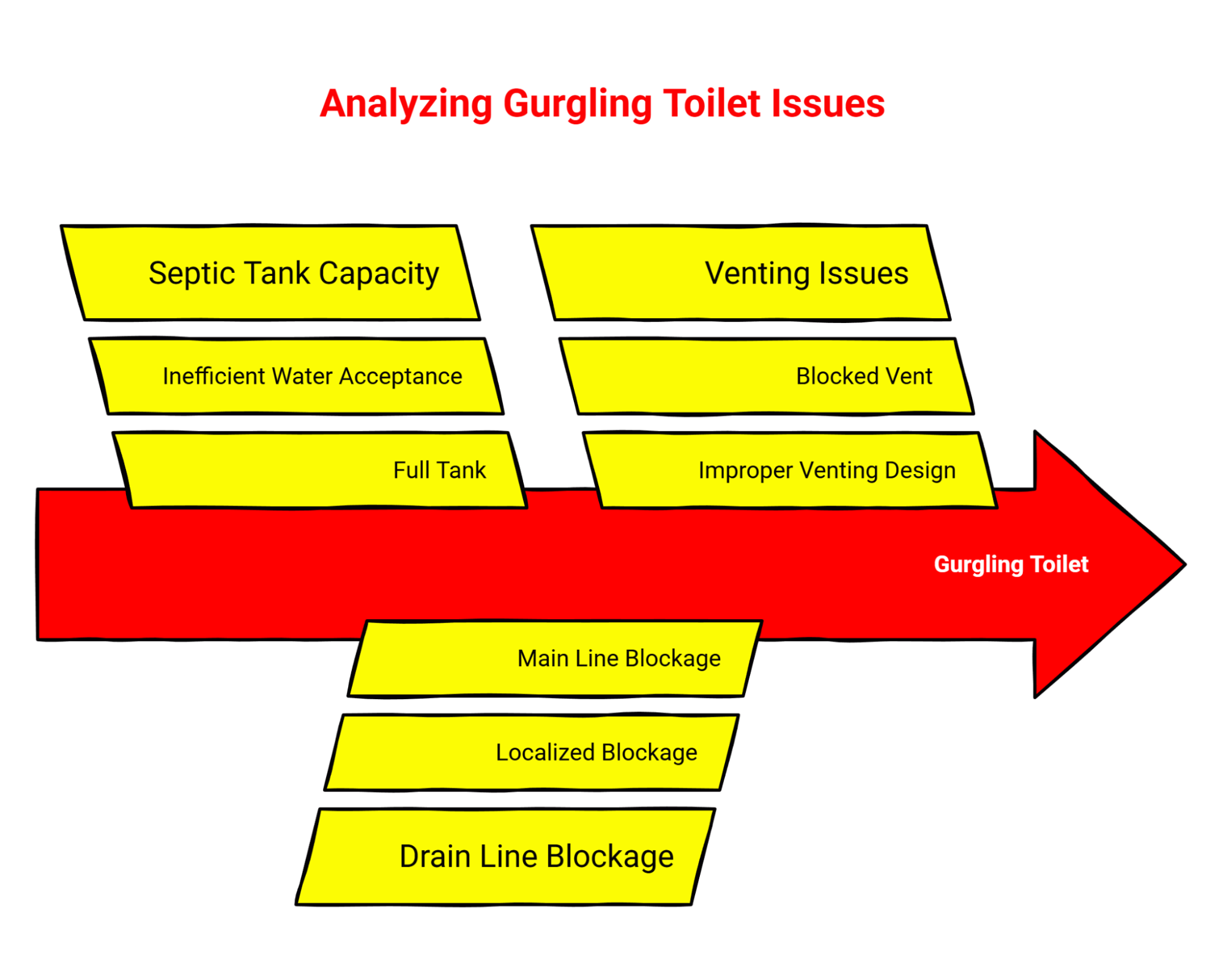

Over time, those sludge and scum layers grow thicker. When they take up too much space, several problems emerge. The tank loses its capacity to separate waste effectively, which means solids can escape into your drain field and cause expensive damage. You might notice slow drains throughout your house, unpleasant odors near the tank or in your yard, or gurgling sounds when you flush toilets or run water.

Pumping removes the accumulated solids and liquids, restoring the tank’s working capacity. Professional Houston septic tank cleaning goes further by including interior cleaning—sometimes with high-pressure hydro-jetting—to break up stubborn, compacted material and truly reset your system.

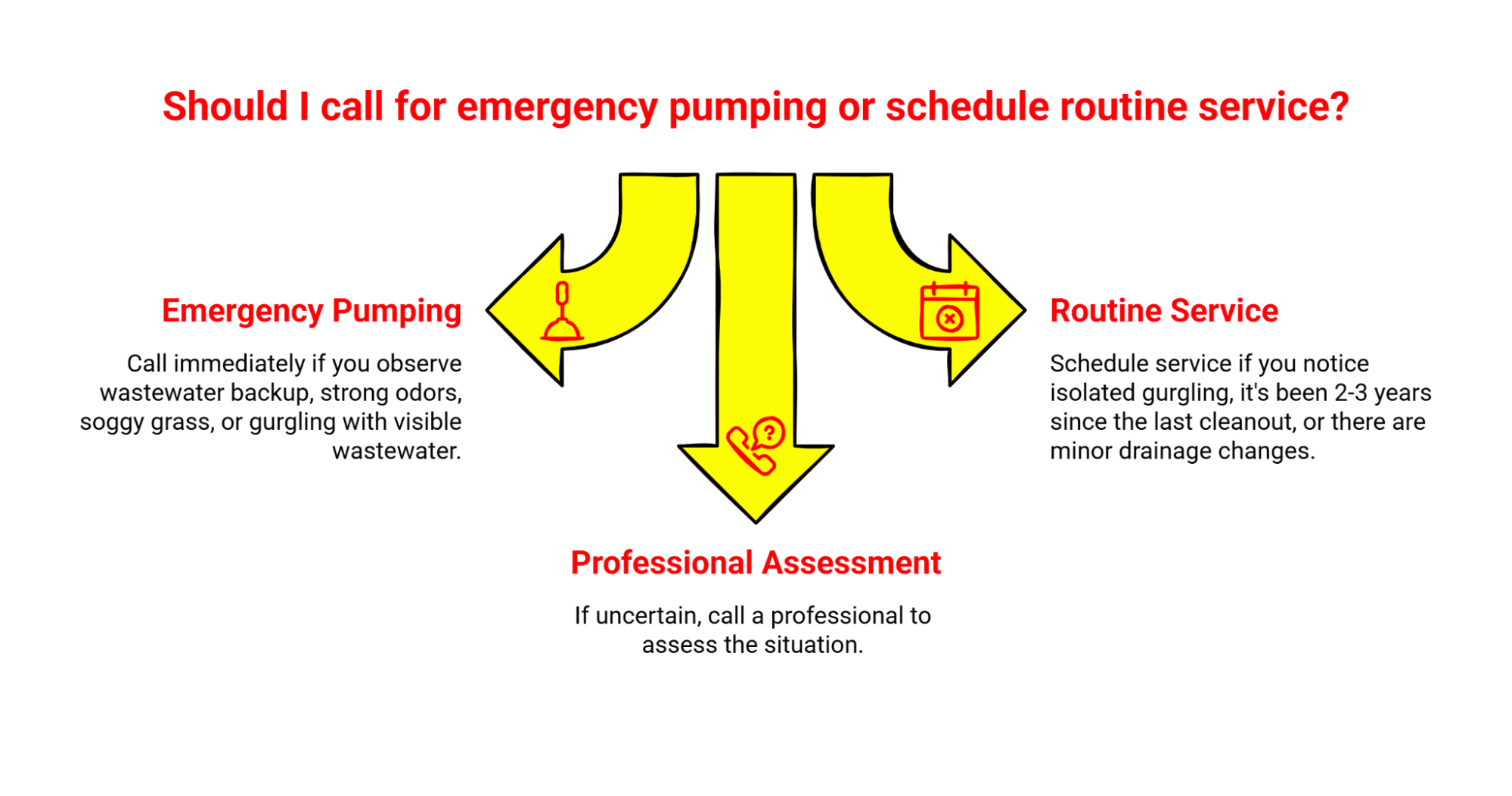

Most households need service every 2–3 years. That baseline shifts based on your household size, tank capacity, water usage patterns, and whether you use a garbage disposal frequently. If you notice any warning signs—sewage odors, slow drains, standing water near the tank, or actual backups—don’t wait for your regular schedule. Call immediately.

Maintaining this routine protects your investment. Septic tank services prevent the kind of catastrophic failures that lead to thousands of dollars in emergency repairs, environmental contamination, and potential health hazards for your family.

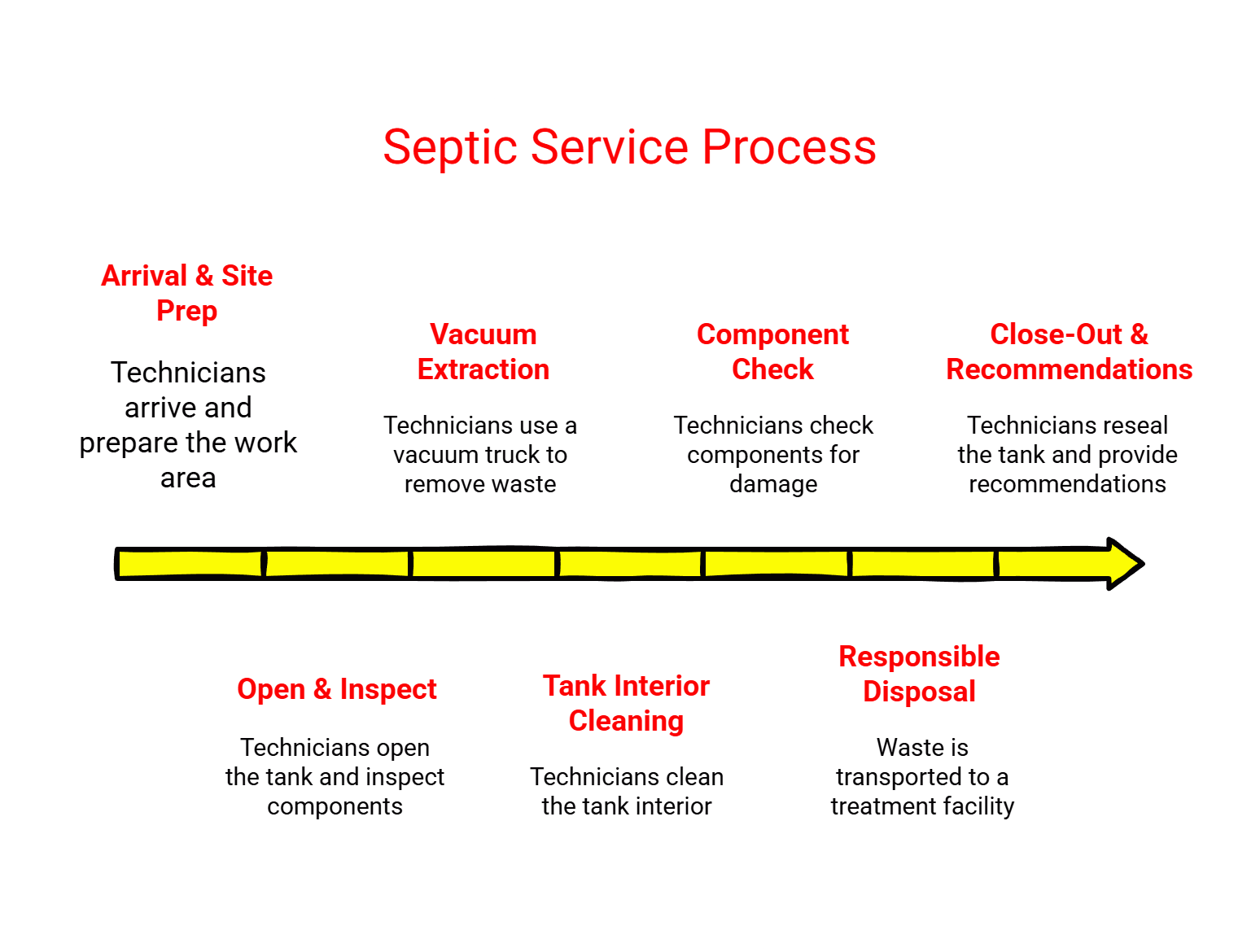

The Pump-Out, Step by Step

Professional septic service follows a systematic process designed to be thorough, safe, and compliant with local regulations. Here’s what happens during a typical service call in Alvin, Pearland, Sugar Land, Friendswood, and across Greater Houston.

Arrival & Site Prep

The service truck arrives at your scheduled time. Technicians confirm the exact location of your tank—sometimes using property records, sometimes following obvious access points like concrete lids or risers. If your tank is buried and the location isn’t immediately clear, they may need your help locating it.

Before opening anything, the crew prepares the work area. They lay down protective covering if needed, move any lawn furniture or decorations, and ensure they have clear access to the lids. This is also when they’ll ask about pets (which should be secured indoors) and verify that there’s adequate space for the vacuum truck’s hose to reach the tank.

Open & Inspect

Technicians carefully remove the tank lids, exposing the interior. This is the first opportunity to assess what’s happening inside. They check the current liquid level and measure the thickness of both the scum layer on top and the sludge layer at the bottom.

A properly functioning tank should have relatively clear liquid in the middle zone, with scum and sludge layers taking up no more than about one-third of the total depth. If the sludge has built up past that point, it’s confirmation that the pump-out is needed.

The crew also inspects the inlet and outlet tees—the T-shaped pipes that direct wastewater into the tank and allow treated liquid to flow out. These components can deteriorate or become clogged with debris, and identifying problems early prevents more serious issues down the line. They examine visible baffles, which help direct flow and keep floating solids away from the outlet.

Vacuum Extraction

This is the core of the service. The technician connects a large-diameter hose from the vacuum truck to the tank opening. The truck’s powerful pump creates suction that pulls liquids and solids out of the tank and into a sealed holding compartment on the vehicle.

For tanks with heavily compacted sludge at the bottom, technicians use the hose to agitate and break up the material, ensuring it can be removed effectively. This step is critical—simply removing the liquid without addressing compacted solids leaves your tank only partially cleaned and shortens the time until your next service.

The extraction continues until the tank is essentially empty, with only a small amount of liquid remaining. This complete removal is what differentiates a thorough pump-out from a partial one.

Tank Interior Cleaning

Once the bulk of the material is out, the real cleaning begins. Technicians rinse the interior walls and floor of the tank, using water pressure to dislodge any stuck-on waste and ensure all surfaces are as clean as possible.

For tanks that haven’t been serviced regularly or show significant buildup, crews may use hydro-jetting—high-pressure water jets that scour the interior surfaces and break apart any remaining compacted material. This process essentially resets the tank to a like-new condition, maximizing efficiency and extending the time until your next service.

The rinse water and dislodged material are vacuumed out as well, leaving the tank clean and ready to resume normal operation.

Component Check

With the tank empty and clean, technicians have a clear view of all the interior components. They re-inspect the inlet and outlet tees, baffles, and the tank walls themselves, looking for cracks, deterioration, or damage that could compromise system function.

This is when problems often come to light. A cracked baffle, a deteriorating tee, or a damaged tank wall might explain issues you’ve been experiencing—slow drains, persistent odors, or gurgling sounds in your plumbing. Identifying these problems now allows for repairs before they cause a complete system failure.

The crew also checks the tank’s structural integrity. Concrete tanks can develop cracks over time, and older tanks may show signs of corrosion or settling. Catching these issues early means you can address them proactively rather than waiting for a costly emergency.

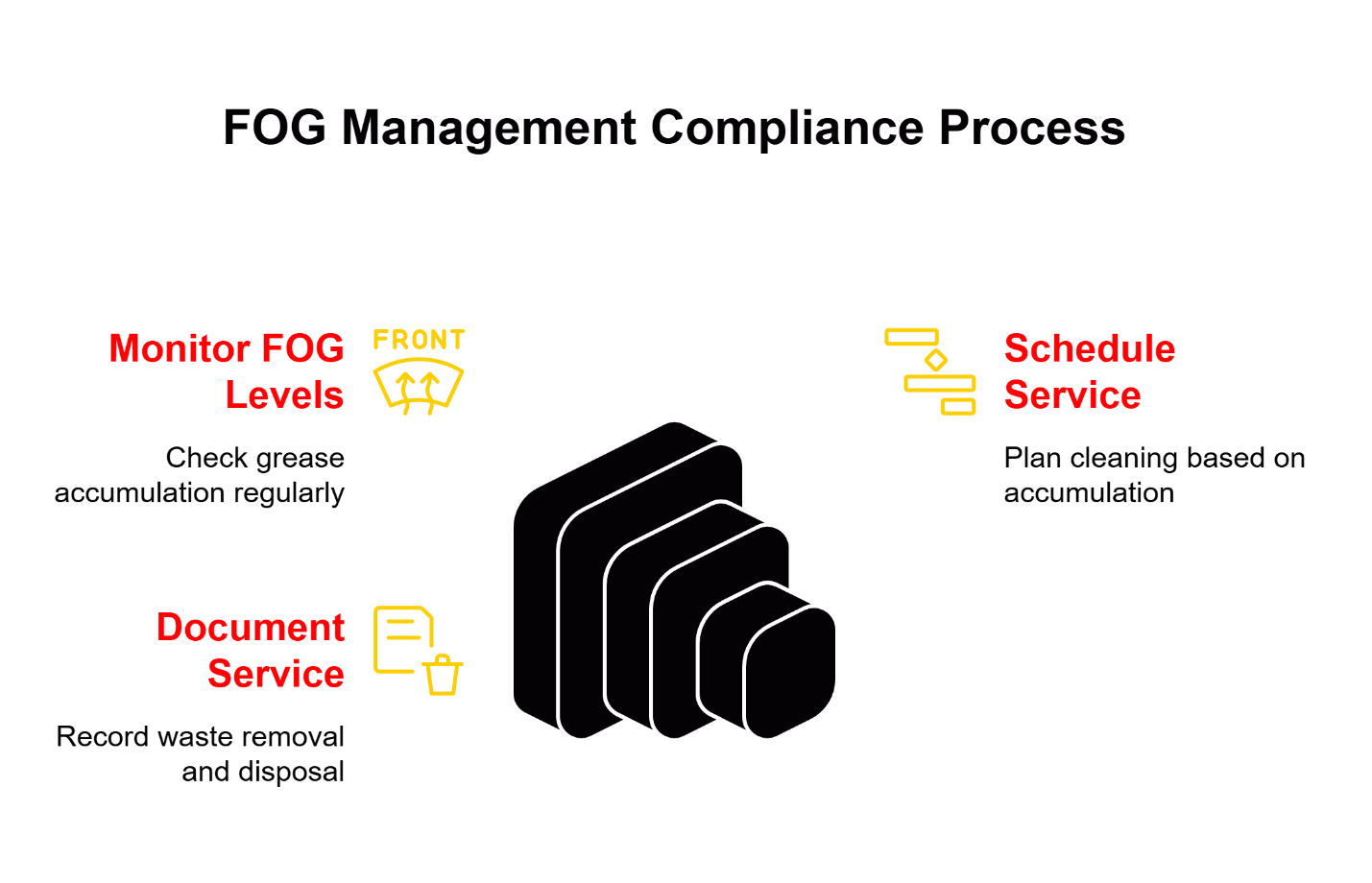

Responsible Disposal

The waste removed from your tank isn’t just dumped anywhere. Professional septic service companies transport it to approved treatment facilities where it’s processed according to environmental regulations. This protects local water sources, prevents contamination, and ensures compliance with all local and state requirements.

Drane Ranger uses vacuum truck services specifically designed for safe, compliant waste handling. The sealed systems on modern vacuum trucks prevent spills and odors during transport, and all disposal follows strict environmental guidelines.

Close-Out & Recommendations

After cleaning and inspection, technicians reseal the tank lids, ensuring they’re secure and properly positioned. They clean up the work area, removing any equipment or protective covering and restoring your property to its original condition.

Before leaving, they provide you with a service record documenting what was done, any issues found, and their recommendations. This typically includes confirmation of your next recommended service date—usually 2–3 years out, though the timeline may be shorter if you have a larger household, a smaller tank, or if they identified any concerns during inspection.

This is also when you can ask questions about anything you noticed—unusual sounds, slow drains, or odors—and get expert advice on whether additional maintenance or repairs might be needed.

How long does a pump-out take?

Most standard residential pump-outs take 60–120 minutes. Time varies with tank size, lid accessibility, sludge thickness, and whether additional cleaning like hydro-jetting is needed. Proper service can’t be rushed—thoroughness matters more than speed.

What We’ll Need From You

To help the service run smoothly:

- Clear access to your septic tank location (or your best guess if lids aren’t visible)

- Pets secured indoors and gates unlocked

- Adequate space in the driveway or along the curb for the vacuum truck

- Any past service records, if available (helpful but not required)

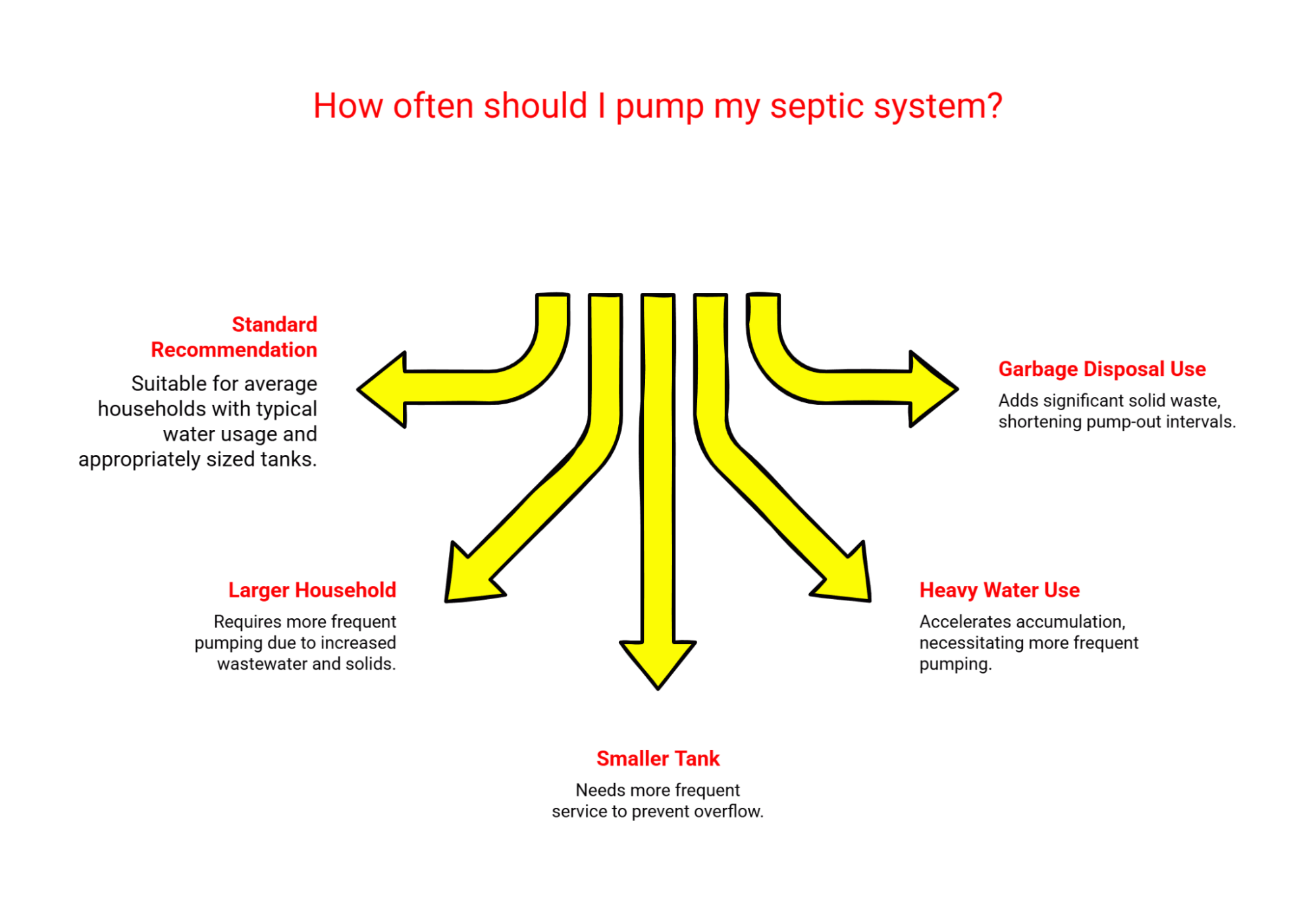

How Often Should You Pump?

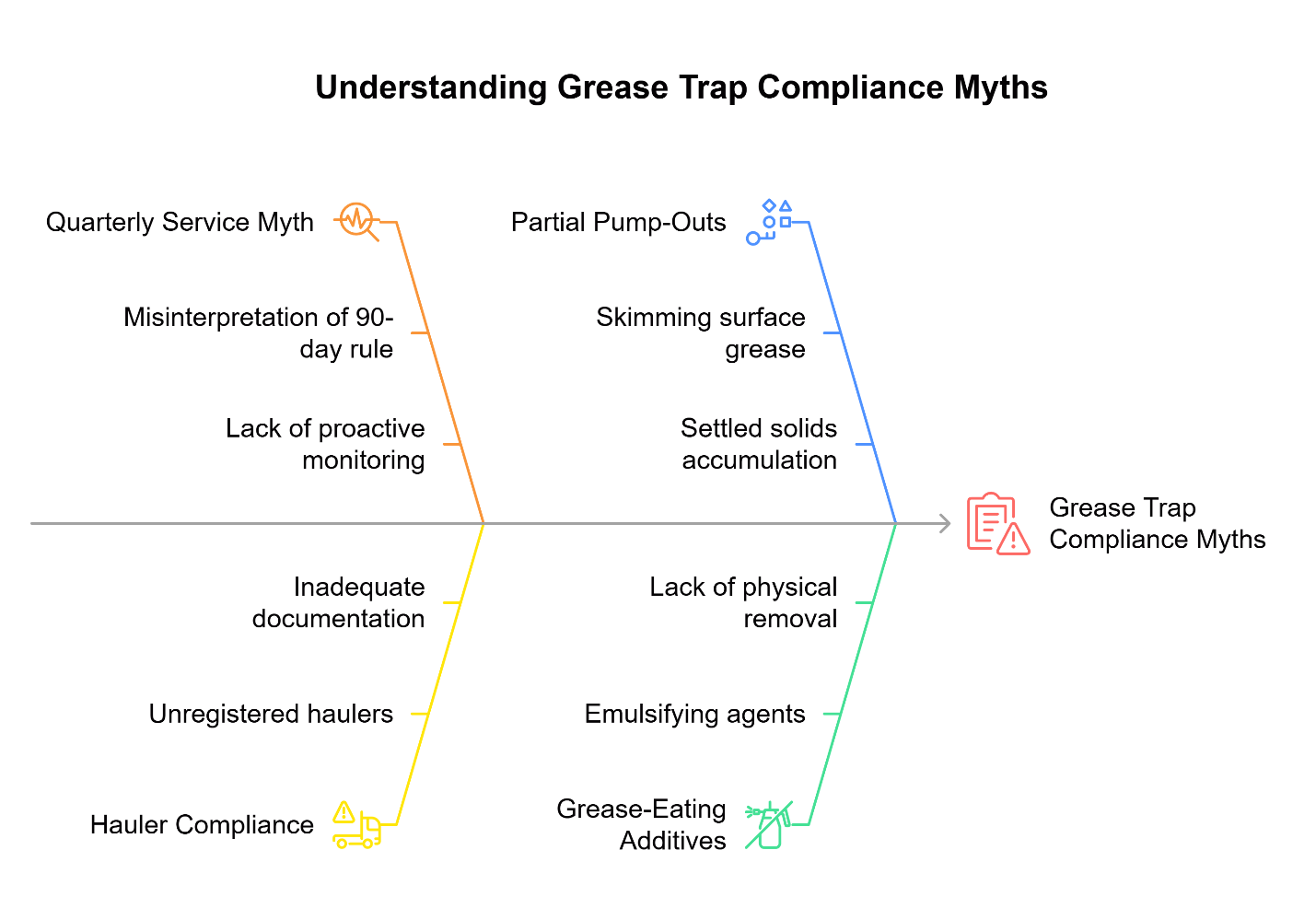

The standard recommendation for most residential septic systems is service every 2–3 years. That baseline assumes average household size, typical water usage, and a tank sized appropriately for the home.

Several factors influence your specific schedule. Larger households generate more wastewater and solids, which means the tank fills faster. If you have a smaller tank relative to your home size, you’ll need more frequent service. Heavy water use—multiple loads of laundry daily, frequent dishwasher cycles—accelerates the accumulation of material in your tank.

Using a garbage disposal regularly adds a significant amount of solid waste to your septic system, which can shorten the interval between pump-outs. Some experts suggest pumping annually if you rely heavily on your disposal.

Septic Health Interval Calculator

Use this as a quick-glance guide. Real-world usage patterns—particularly garbage disposal use and high water consumption—may shorten these intervals. Act sooner if you notice warning signs like odors, slow drains, or standing water.

| Household Size | Tank Size (Gallons) | Recommended Interval |

| 1-2 people | 750-1,000 | Every 3-4 years* |

| 3-4 people | 1,000-1,250 | Every 2-3 years* |

| 5-6 people | 1,250-1,500 | Every 1-2 years* |

| 7+ people | 1,500+ | Annually* |

*Act sooner if you notice warning signs. Usage patterns may require shorter intervals.

Warning signs override any schedule. If you smell sewage odors outside your home, notice slow drains or gurgling sounds, see standing water or unusually lush grass near your tank location, or experience any sewage backup, contact a professional immediately. These symptoms suggest your tank is full or your system is experiencing a failure that requires urgent attention.

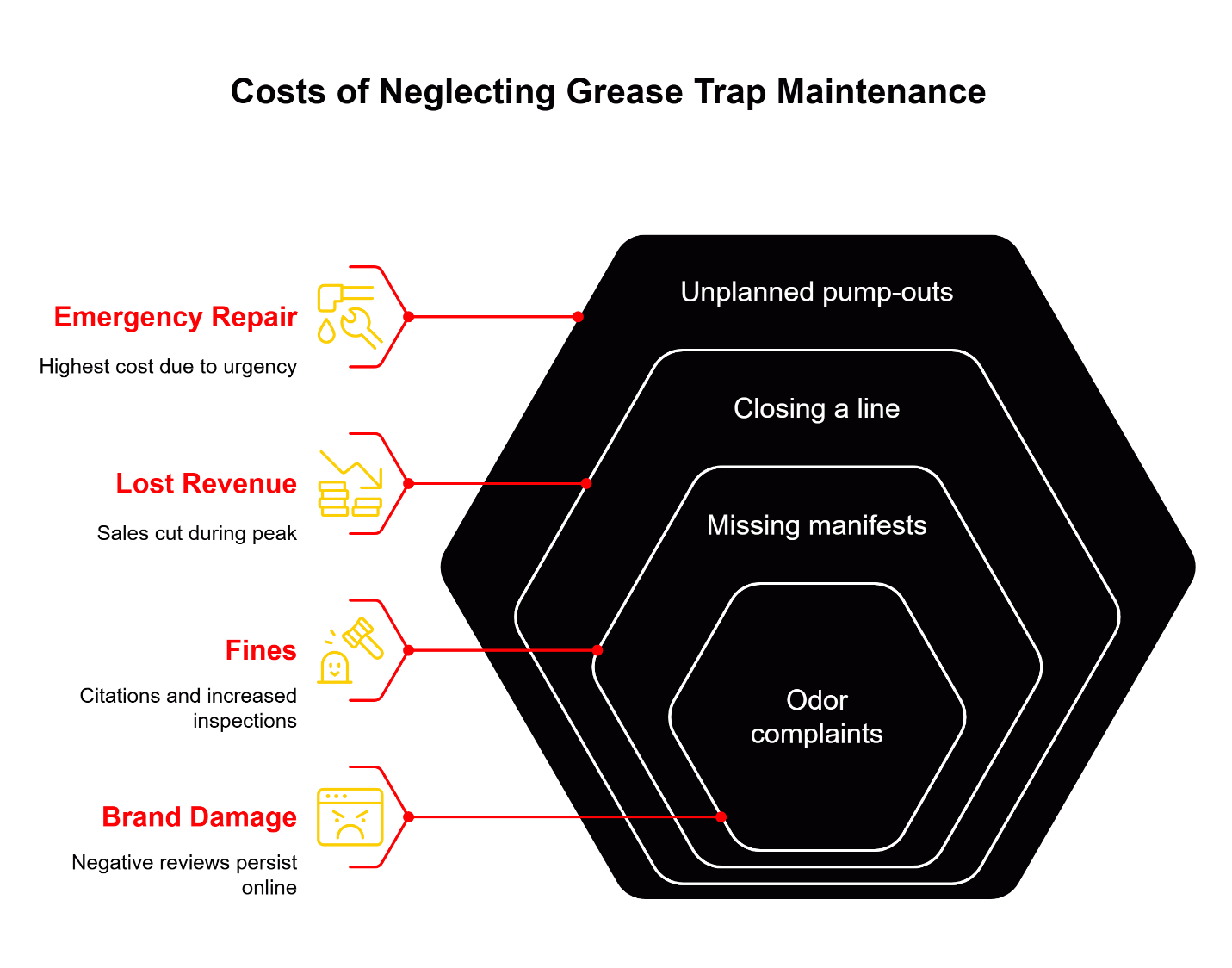

What It Costs to Wait (and Why It’s Risky)

Delaying septic maintenance seems like a way to save money, but the opposite is true. A neglected septic system leads to increasingly serious problems that become exponentially more expensive to fix.

When your tank overfills, solids begin escaping into your drain field. The drain field is designed to handle clear liquid, not solid waste. Solids clog the soil pores, preventing proper drainage and causing sewage to back up onto your property. Drain field replacement typically costs $5,000 to $20,000 or more—a devastating expense compared to routine $300-500 pump-outs.

Sewage backups create immediate health hazards. Raw sewage contains bacteria, viruses, and parasites that pose serious risks to your family and pets. The Environmental Protection Agency’s guidance on septic systems emphasizes that proper maintenance protects both household health and community water quality. Cleanup after a backup often requires professional remediation services, and contaminated areas of your home may need extensive restoration.

Environmental damage is another consequence. Failed septic systems contaminate groundwater and surface water with harmful pathogens and nutrients. The Texas Commission on Environmental Quality provides detailed regulations for on-site sewage facilities, and homeowners are legally responsible for maintaining compliant systems. Violations can result in substantial fines and mandatory costly repairs.

Property damage extends beyond the drain field. As the CDC notes in its wastewater and health guidance, sewage pooling in your yard kills vegetation, creates foul odors, and may even compromise your home’s foundation if backups occur into the basement. The longer the problem persists, the more extensive—and expensive—the damage becomes.

Regular maintenance prevents all of this. A routine pump-out every 2-3 years protects your system’s lifespan, prevents emergencies, and maintains your property value. It’s not an expense; it’s an investment in avoiding catastrophic failure.

Why Choose Drane Ranger in Greater Houston

Since 1985, Drane Ranger has been the trusted name for septic service throughout the Greater Houston area. Our team combines decades of experience with ongoing training to ensure every service call meets the highest standards for quality and customer care.

Our technicians are trained, certified professionals who understand both the technical requirements of septic systems and the importance of treating your property with respect. We arrive on time, complete the work efficiently, and leave your property clean—commitments we’ve upheld for nearly 40 years.

We serve a comprehensive area within a 100-mile radius of Houston, including Alvin, Pearland, Sugar Land, Friendswood, League City, Manvel, Rosharon, Angleton, and Texas City. Whether you’re in Harris County, Fort Bend County, Montgomery County, Brazoria County, or Galveston County, our team is ready to help.

Our fleet of modern vacuum trucks represents significant investment in equipment that makes the job faster, cleaner, and more thorough. High-capacity systems mean we can handle any residential tank size, and our trucks are maintained to the highest standards for reliability and environmental compliance.

One customer captured the experience well: “My experience with Drane Ranger was a very organized, professional and on time experience. I was kept informed of what was happening and a suggested time of cleaning again. I will use them again and will definitely recommend them to anyone I speak with.” — Harold R.

When you choose Drane Ranger, you’re choosing a company that stands behind its work and genuinely cares about protecting your investment. We don’t just pump tanks—we build long-term relationships with homeowners who trust us to keep their systems running properly year after year.

Frequently Asked Questions

Is pumping the same as cleaning?

Pumping removes liquids and sludge from your tank, but cleaning goes further. Professional cleaning may include hydro-jetting and thorough scrubbing of interior surfaces to fully reset your tank and remove compacted material that pumping alone might miss.

How often do I need it?

Every 2–3 years for most homes, though your specific schedule depends on household size, tank capacity, and water usage. Act sooner if you notice odors, slow drains, or backups—these are warning signs that shouldn’t be ignored.

What if I smell sewage outside?

Call now. Sewage odors outside your home could indicate an overfilled tank, a crack in the tank or pipes, or a drain field issue. All of these require professional assessment and prompt attention to prevent more serious problems.

Do you cover my area?

Yes—we serve Greater Houston within a 100-mile radius. Our service area includes Houston, Alvin, Pearland, Sugar Land, Friendswood, League City, Manvel, Rosharon, Angleton, Texas City, and surrounding communities in Harris, Fort Bend, Montgomery, Brazoria, and Galveston counties.

How do you dispose of waste?

All waste is handled and disposed of responsibly in full compliance with local environmental regulations. We transport waste to approved treatment facilities where it’s processed safely, protecting local water sources and the environment.

Ready to schedule your service? Call us at 281-489-1765 (Mon–Fri, 9am–6pm) or contact us today to request your quote.

For homeowners who want to prepare thoroughly, download our free Pump-Out Day Checklist—a one-page guide covering everything you need to have ready before the crew arrives.

Disclaimer: This guide is intended as a comprehensive starting point. For decisions specific to your unique situation, we always recommend consulting a qualified professional.

Our Editorial Process

All content undergoes multi-stage review including technical accuracy verification against TCEQ model standards, local regulation compliance checking, and practical application testing. We distinguish between verified regulatory requirements and generally accepted industry practices to help operators understand certainty levels.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.