📌 Key Takeaways

Organized grease trap documentation transforms Houston city audits from stressful scrambles into quick verifications.

- Manifests Prove Legal Disposal: Invoices show payment, but only signed manifests with disposal facility stamps prove your waste was disposed of legally.

- Five-Year Retention Required: Houston inspectors may request grease trap manifests going back five years during routine or complaint-driven inspections without advance notice.

- Reverse Chronological Filing Wins: Filing newest manifests first lets inspectors verify your 90-day service compliance pattern in seconds, not minutes.

- Digital Backups Prevent Disasters: Scanning manifests within 24 hours using consistent naming conventions ensures one lost binder doesn’t expose you to citations.

- Invalid Manifests Invite Scrutiny: Missing driver signatures, generator signatures, or disposal facility stamps make manifests worthless and trigger deeper investigations.

Complete documentation = operational confidence during unannounced inspections.

Houston restaurant managers and owners responsible for FOG compliance will gain a clear action plan here, preparing them for the detailed binder setup checklist that follows.

The inspector’s clipboard is out. Your manager is stalling. And you realize—nobody knows where the manifests are filed.

This scenario plays out across Houston restaurants more often than it should. In a city with strict environmental regulations, operational negligence is a choice that leads to inevitable disruption. Grease trap documentation is the audit trail—manifests, permits, and inspection records—that proves your fats, oils, and grease (FOG) waste was removed and disposed of legally. Think of it like your tax receipts: if you can’t show them when asked, it doesn’t matter what you actually paid.

Here’s what that looks like in practice. It’s Friday during dinner rush when a health inspector arrives and asks for your last five years of manifests. Your host scrambles to find a manager. The manager searches three different filing cabinets and a desk drawer. Twenty minutes later, you’re still producing random invoices while the inspector waits—and grows increasingly interested in what else might be wrong.

The good news? You can put a simple binder and digital folder system in place today so inspections become a streamlined verification instead of a 45-minute ordeal.

What a Houston City Audit Usually Means (And Why It’s Stressful)

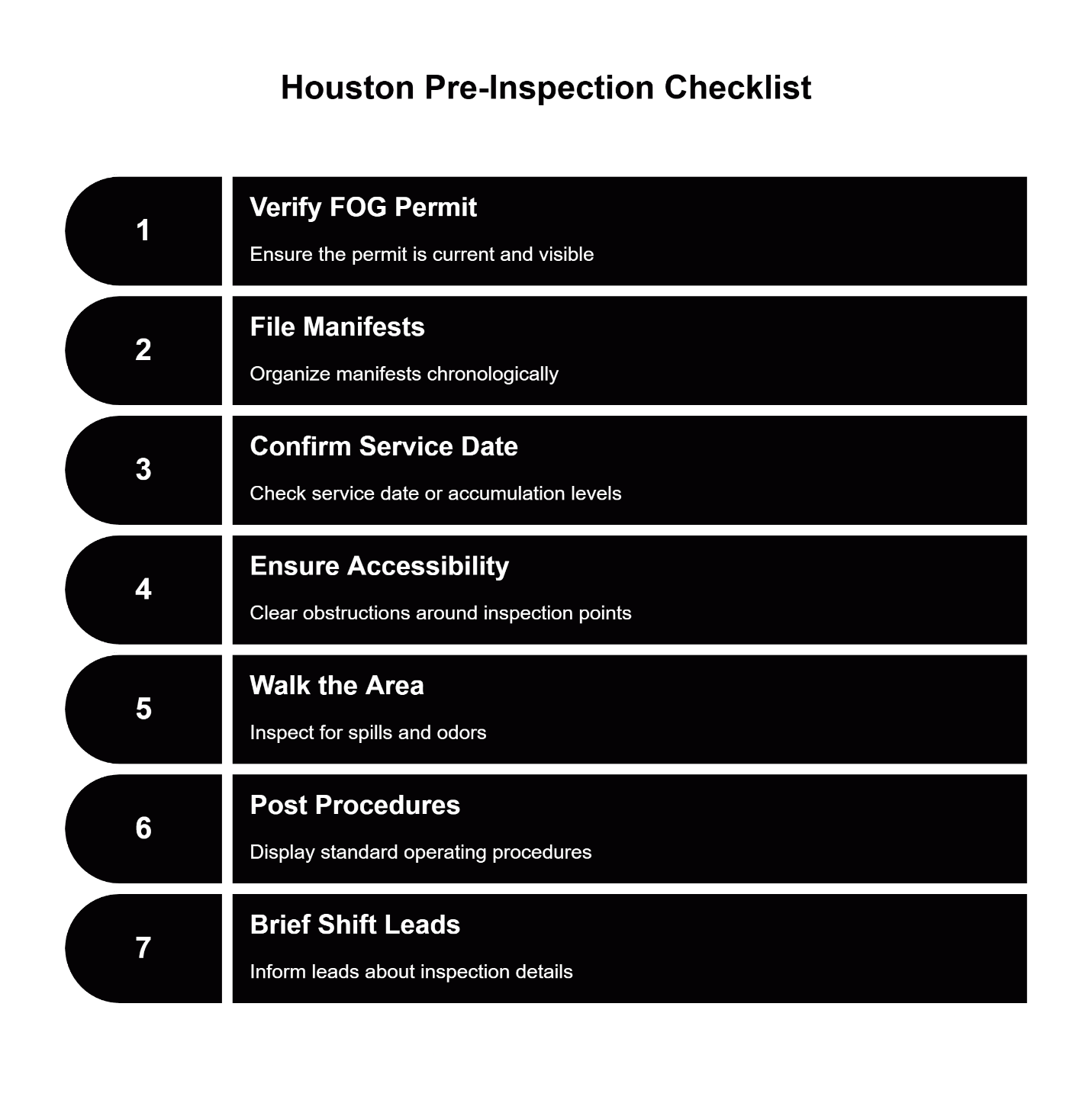

You may be inspected without warning, and the stress comes from two places: not knowing when an inspection will happen, and not being certain you can find everything when it does.

In Houston, you may be inspected routinely or after a complaint, and you can be expected to produce your FOG permit and historical manifests on request—often without prior notice.[^1] Inspections can happen any day your business is open, and the inspector has the authority to request specific documents immediately.

If your manager can’t produce those documents quickly and completely, the inspector has reason to look deeper. What started as a routine compliance check becomes a more thorough investigation of your entire grease trap management system.

Your binder is your first line of defense. A well-organized compliance binder demonstrates operational competence before the inspector asks a single question. It shows you take your environmental responsibilities seriously, and it transforms a potentially adversarial encounter into a quick verification.

Most audit failures aren’t cleaning failures—they’re documentation failures. Your trap might be pumped on schedule, but if you can’t prove it with proper manifests, you’re exposed to citations and follow-up inspections.

The Exact Documents to Keep in Your Binder (Houston Checklist)

Houston inspectors typically request these specific documents during an inspection:[^1]

- Current FOG permit (both the copy posted in your facility and a binder copy with renewal date noted)

- Waste manifests for the past 5 years (both the initial generator copy and the final return copy received from your hauler)

- Notice of Waiver (if you’ve been granted any exceptions to standard requirements)

- Copies of previous inspections (including any follow-up documentation)

- Authorization letter for any biological additives (Note: Use of enzymes or bacteria requires specific City approval per Sec. 47-748; do not file invoices for unpermitted additives)

File every copy you receive from your grease trap service provider. Don’t assume the office copy or the email confirmation is sufficient. The inspector wants to see the physical manifest with the required signatures and stamps, which we’ll cover in detail below.

Keep these documents organized by type and date. When an inspector asks to see “manifests from 2022,” you should be able to hand them a complete set within seconds, not start searching through mixed piles of papers.

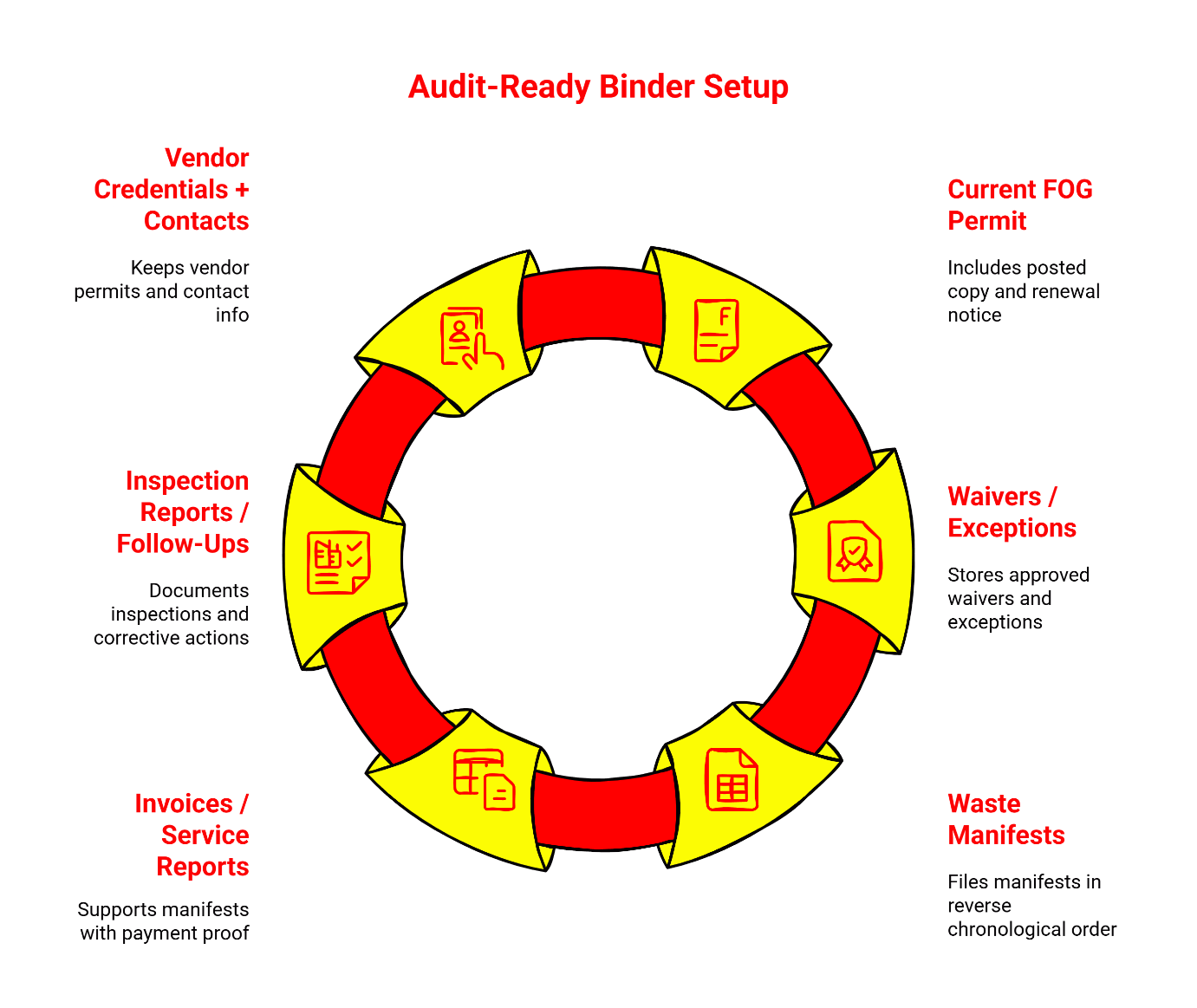

The Audit-Ready Binder Setup (10 Minutes, No Fancy Tools)

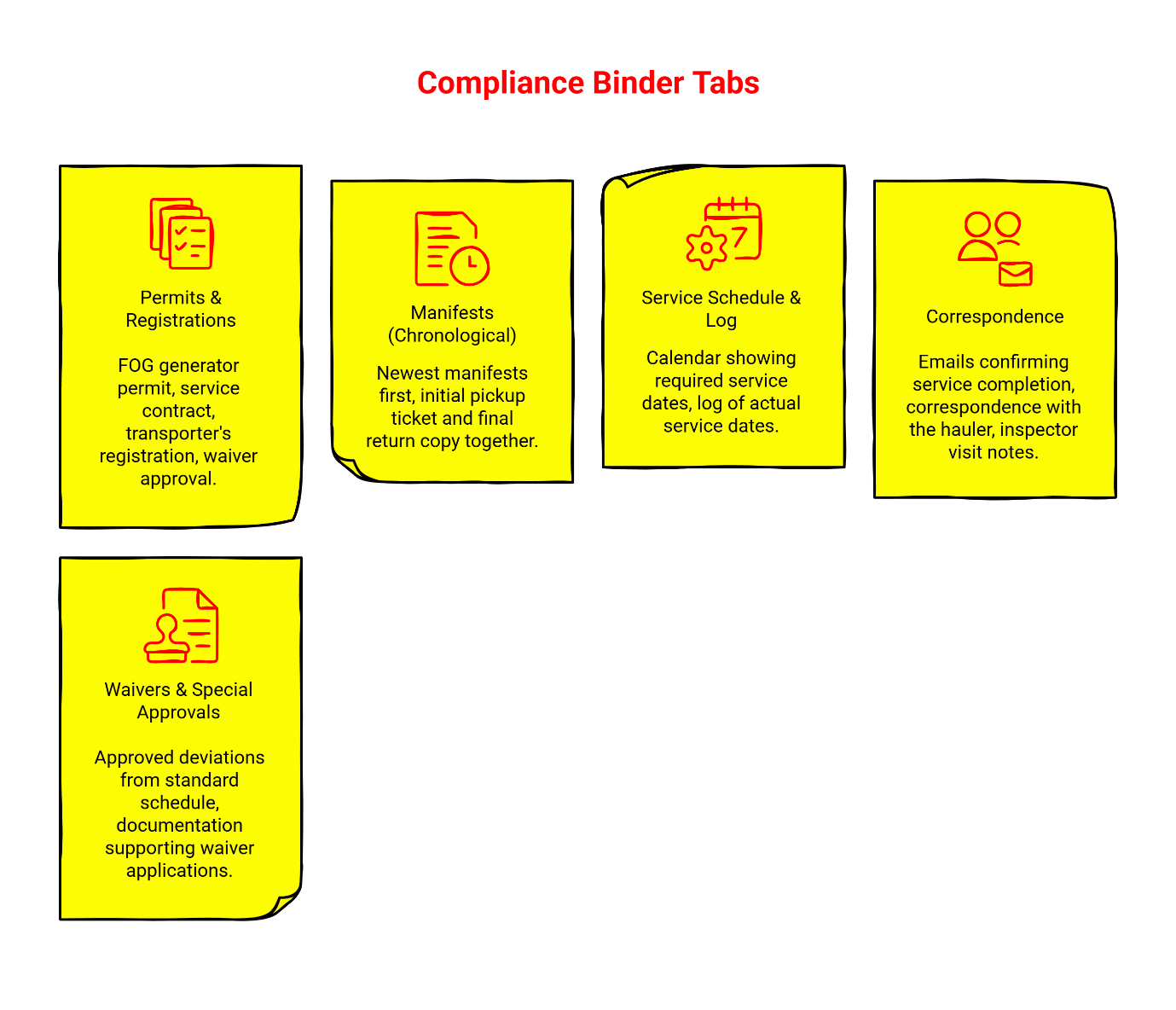

Use a single three-ring binder with clear tab dividers. Label the spine clearly: FOG / Grease Trap Compliance Binder (Houston). This becomes your single source of truth for all compliance documentation.

Set up six tabs in this exact order:

Tab 1: Current FOG Permit

File both the posted copy and your renewal notice here. Note the expiration date prominently on the tab itself so you never miss a renewal deadline.

Tab 2: Waivers / Exceptions

If you’ve been granted any waivers or exceptions to standard requirements, file them here with clear dates showing when they were approved and when they expire.

Tab 3: Waste Manifests (5 years, reverse chronological)

This is your most important section. File the newest manifest first—this reverse chronological order lets you answer “When was your last pump-out?” in five seconds. When you receive a new manifest, punch holes and place it at the front of this section. Staple any related invoice or service report behind each manifest (invoice supports, manifest protects).

Tab 4: Invoices / Service Reports

Supporting documentation goes here, but remember: this tab supplements Tab 3, it doesn’t replace it. Manifests are legal proof of disposal; invoices are merely proof of payment.

Tab 5: Inspection Reports / Follow-Ups

Every time you’re inspected, file the report here along with any corrective action documentation or follow-up correspondence.

Tab 6: Vendor Credentials + Contacts

Keep a copy of your service provider’s current permits, registration documents, and emergency contact information. If something goes wrong at 2 AM, you need this information immediately accessible.

A messy file cabinet is a red flag to an inspector. A clean, organized binder sends the opposite message: this operation takes compliance seriously.

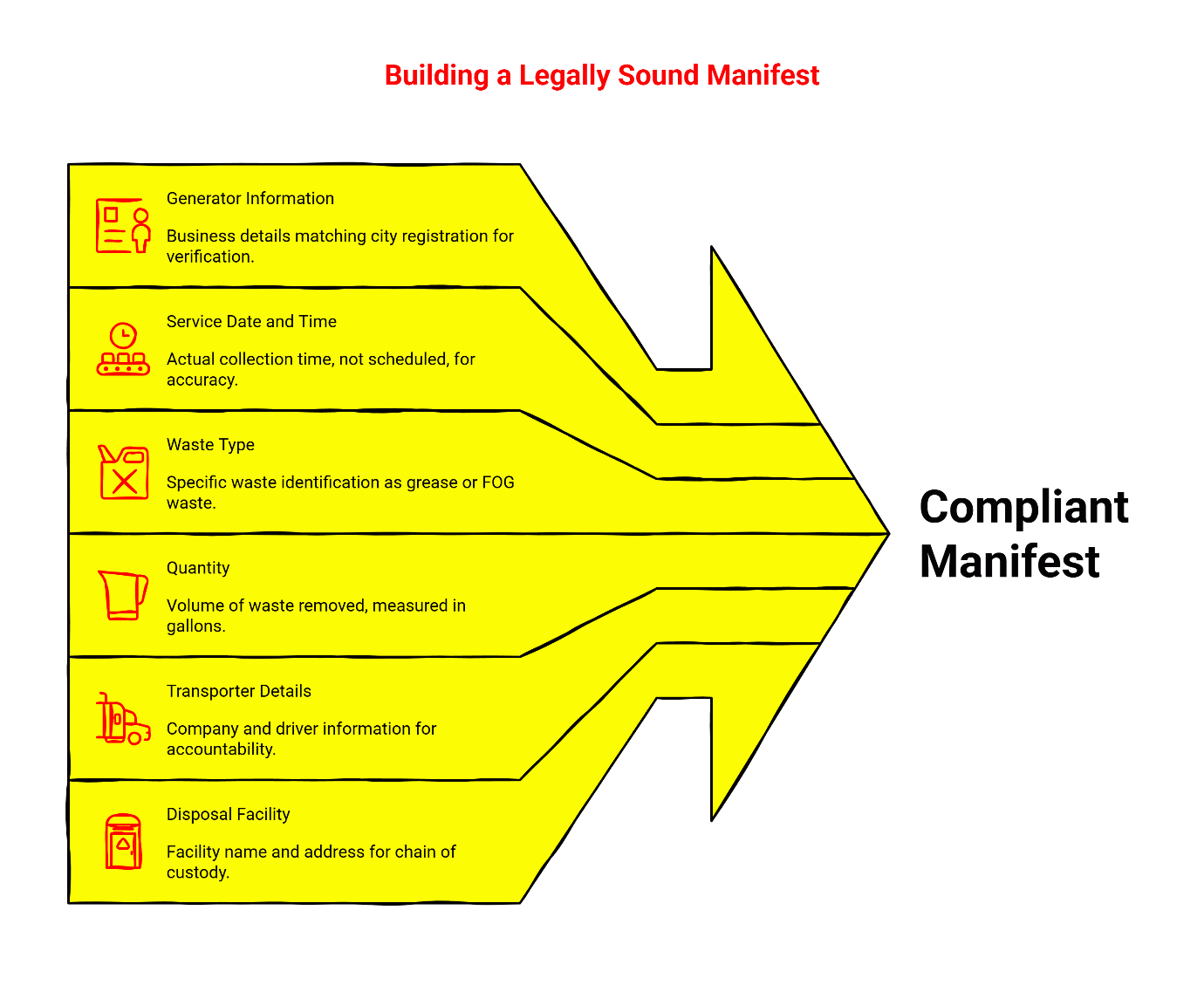

The Manifest Checklist That Actually Protects You

An invoice proves payment. A manifest proves legal disposal. These are not the same document.

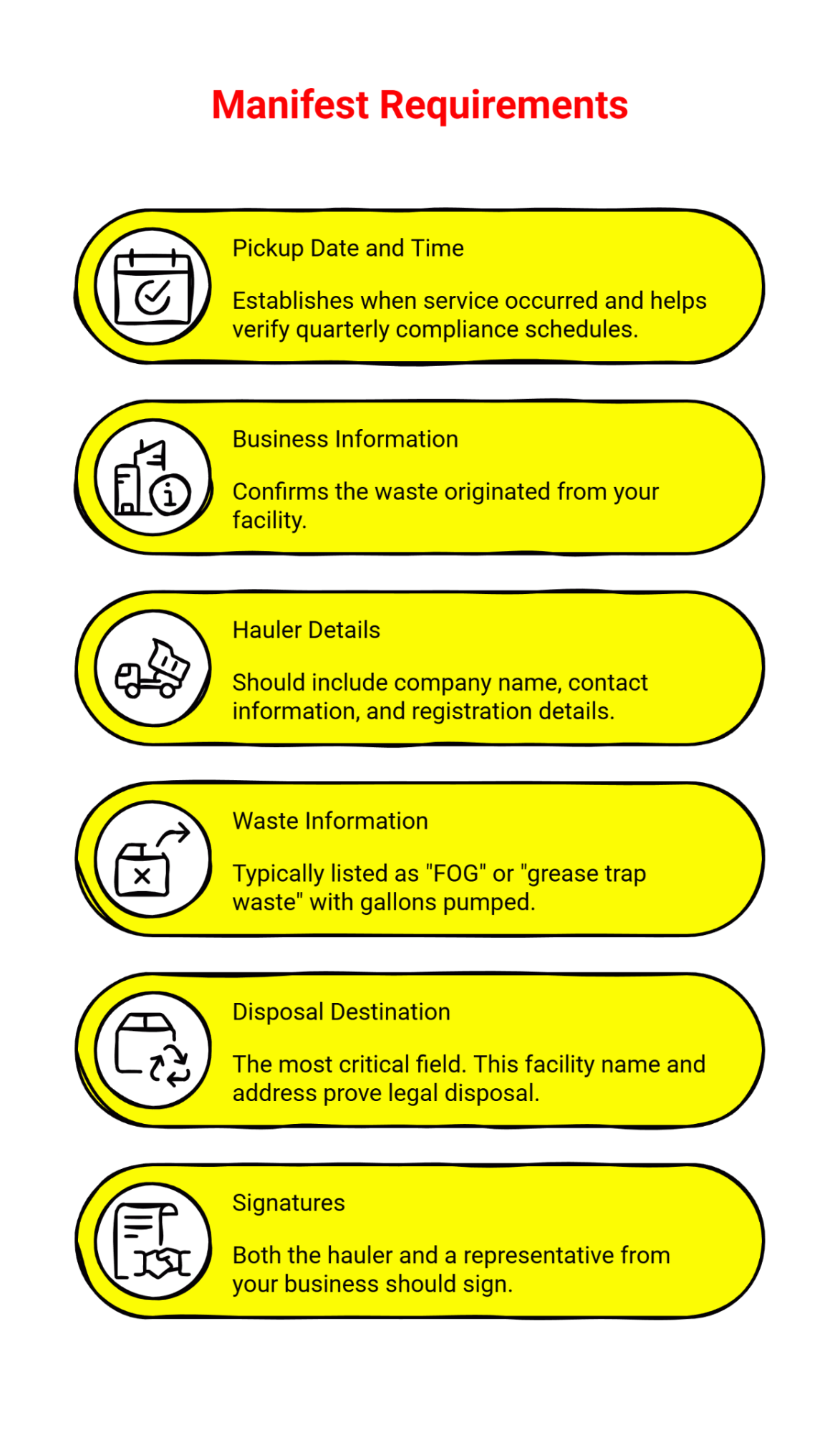

Not all manifests are created equal. A valid manifest must meet specific requirements to serve as legal proof of disposal.[^2] Here’s what you need to verify every time your hauler provides paperwork:

Confirm the manifest is present, not just an invoice. Many restaurant owners discover too late that they’ve been filing invoices for years while the actual manifests went missing. An invoice proves payment. A manifest proves legal disposal.

Confirm it is signed by the driver and your representative before the truck leaves. Both signatures must be present for the manifest to be valid. If your manager wasn’t on site during service, establish a clear protocol for after-hours authorization. Some operators designate backup signers or implement a call-back verification system.

Confirm it is signed and date-stamped by the disposal site. The manifest should show where the waste actually went and when it arrived. This disposal facility information completes the chain of custody that protects you during an audit.

Confirm the paperwork matches your business name, address, and service date. Transposed numbers or wrong addresses can invalidate a manifest. Check these details before your hauler leaves, not weeks later when you’re preparing for an inspection.

Confirm it uses the appropriate paperwork for city-regulated waste. For waste originating within Houston city limits, Houston requires use of a City of Houston manifest with proper signatures at pickup and disposal.[^2] Your hauler should be registered with the appropriate authorities. Using an unpermitted “cheap hauler” doesn’t just risk fines—it transfers liability for improper disposal directly to you as the waste generator.[^4]

These checks take less than two minutes but they’re the difference between audit-ready documentation and worthless paperwork.

Organize by Date, Not by Vendor (How to Prove Consistency)

Inspectors think in timelines—so your binder should too. When an inspector asks “When was your last pump-out?” or “Show me your service history for the past year,” they’re evaluating whether you’re maintaining the required frequency.

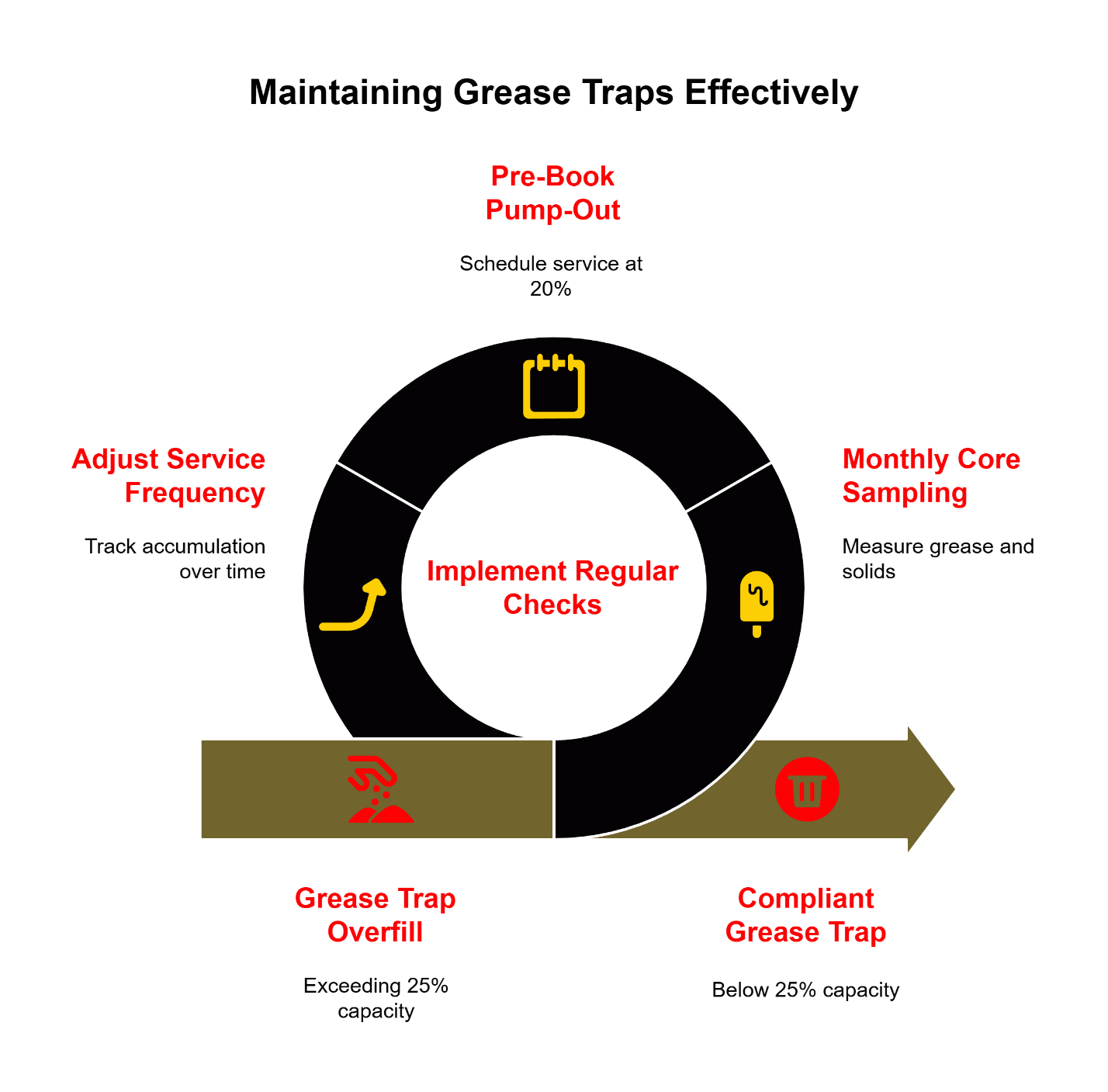

Houston requires that grease interceptors be fully evacuated at least quarterly (every 90 days) unless a waiver has been approved.[^3] Filing manifests in reverse chronological order (newest first) lets you demonstrate compliance instantly. The inspector can flip through your Tab 3 and see at a glance that services occurred on March 15, December 10, September 8, and June 5—a clear pattern of consistent compliance.

If you file by vendor instead, you fragment your timeline. The inspector has to hunt through multiple sections to reconstruct your service history, which wastes time and creates opportunities for them to notice other issues while searching.

Reverse chronological filing also helps you catch problems before the inspector does. When you file your newest manifest, you immediately see how long it’s been since the previous service. If you notice you’re approaching the 90-day mark, you can schedule proactively instead of waiting for the calendar reminder or, worse, discovering you’re overdue when the inspector arrives.

For detailed guidance on scheduling and the 25% rule that can require more frequent service, see our article on when to schedule your pump-out to stay compliant.

Add a Digital Backup (So One Lost Binder Doesn’t Sink You)

Physical binders can be damaged, lost, or incomplete. A digital backup system ensures you’re never completely exposed, even if your paper records disappear.

Set up a shared drive folder structure like this:

/FOG-Compliance/01-Permit

/FOG-Compliance/02-Waivers

/FOG-Compliance/03-Manifests/2025

/FOG-Compliance/03-Manifests/2024

/FOG-Compliance/04-Invoices-Service-Reports/2025

/FOG-Compliance/05-Inspections

Scan each manifest immediately after service using a consistent file naming convention: YYYY-MM-DD_VENDORNAME_TRAPLOCATION_MANIFEST#.pdf

For example: 2024-12-15_DraneRanger_MainKitchen_Manifest8472.pdf

This naming system lets you find any document instantly, even years later. When an inspector asks for December 2022 manifests, you can pull them from your digital folder in seconds as a backup while presenting your physical binder.

Set folder permissions carefully. Assign one editor (typically the facilities manager or owner) and multiple viewers (managers who might need to access documents during an inspection). This prevents accidental deletions while ensuring accessibility.

Update your digital backup within 24 hours of each service. The worst time to discover your scanning protocol isn’t working is during an inspection when you realize your physical binder is incomplete.

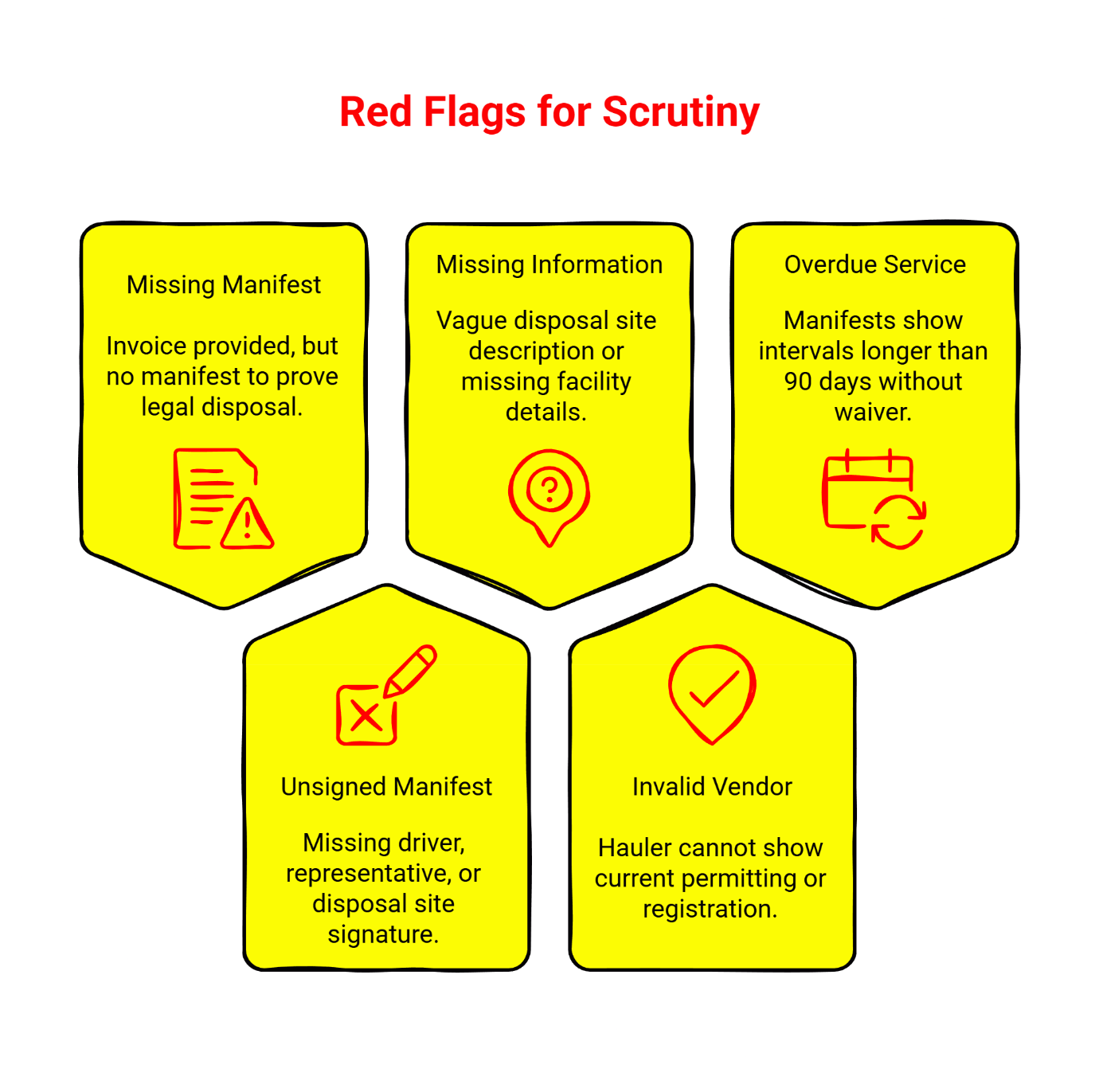

Red Flags That Trigger Extra Scrutiny

Certain documentation problems don’t just fail to protect you—they actively invite deeper investigation. Inspectors are trained to recognize these warning signs:

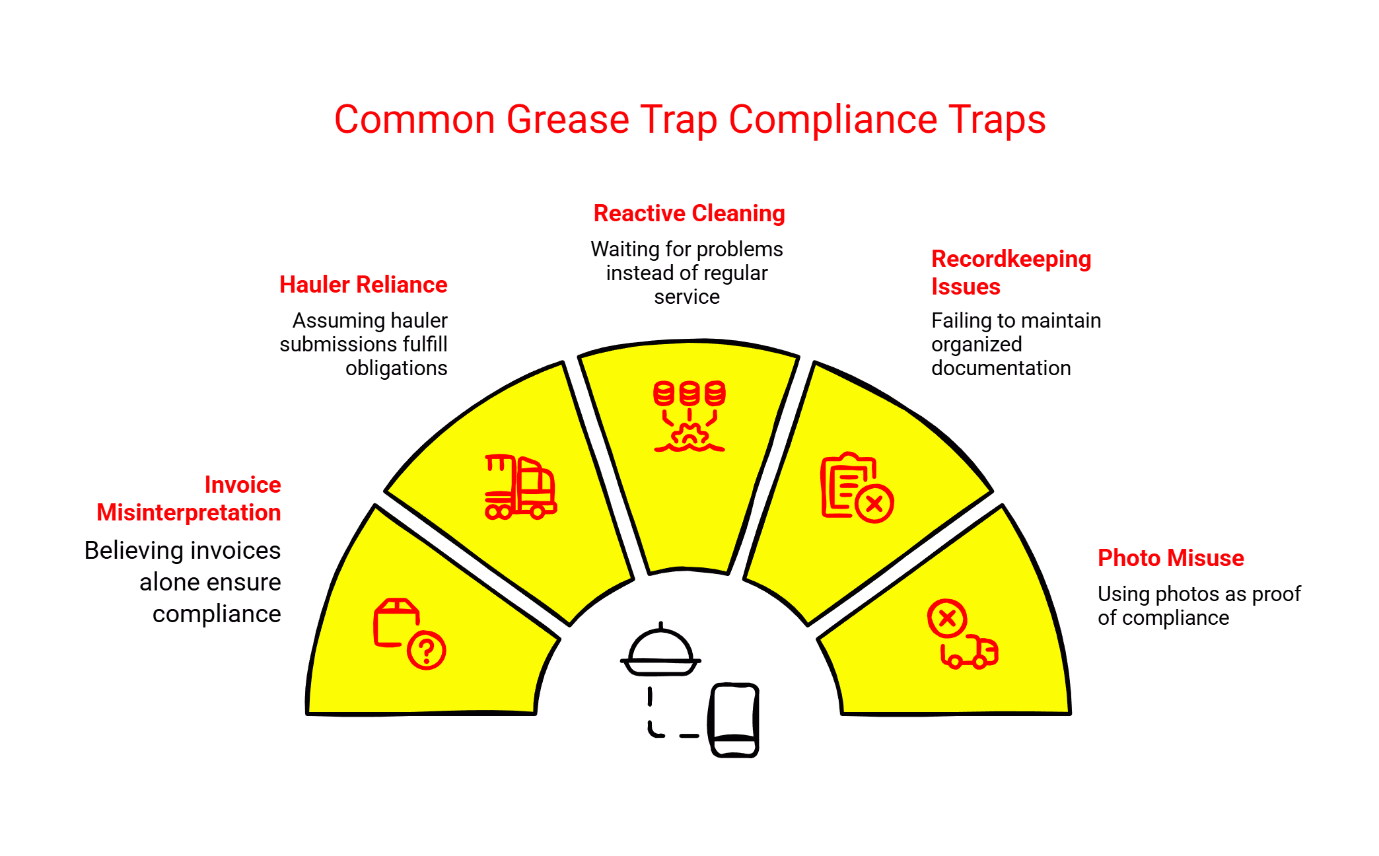

Invoice provided but no manifest. This is the single most common documentation failure. Many restaurant operators believe an invoice proves compliance, but it only proves payment. Without the manifest, you have no proof of legal disposal.

Unsigned manifest. If either the driver signature, your representative’s signature, or the disposal site stamp is missing, the manifest is incomplete. Some operators try to add signatures after the fact, but handwritten additions that don’t match the original ink or pen are obvious red flags.

Missing disposal site information. The manifest must show exactly where the waste was taken and provide enough detail for the city to verify proper disposal. Vague descriptions or missing facility information suggest the waste might not have been disposed of legally.

Vendor cannot show current permitting or registration. If your hauler can’t produce current credentials, any manifests they’ve provided may be invalid. The city requires that transporters maintain proper permits and use authorized manifests for waste originating within Houston city limits.[^2]

Overdue service cadence with no waiver on file. If your manifests show intervals longer than 90 days and you don’t have an approved waiver, you’re operating outside the baseline requirement. The inspector will want to know why.

Understanding why visual checks fail to detect sludge buildup can help you avoid one of the most common reasons restaurants fall out of compliance between scheduled services.

Vendor Questions That Prevent Paperwork Disasters

Not all grease trap service providers deliver audit-ready documentation. Before you sign a service contract, ask these five questions and verify the answers:

- “Will you provide a City of Houston manifest with every service?” The answer must be yes, with no exceptions. Some haulers only provide invoices unless you specifically request manifests.

- “Will the manifest be signed by your driver and our manager before leaving the site?” Both signatures should be obtained before the truck departs. Manifests signed later or off-site raise validity questions.

- “Will the disposal site stamp and sign the manifest before returning it to us?” The completed manifest with disposal facility verification should be returned to you, not kept only by the hauler.

- “Are you currently permitted and registered to transport special waste in Houston?” Ask to see current documentation. Texas regulations require proper registration,[^4] and using an unpermitted hauler can make you liable for their disposal practices.

- “If you come after hours and no one is here to sign, what’s your authorization process?” Some restaurants receive overnight or early-morning service when managers aren’t present. Houston guidance addresses servicing a generator with no representative on-site through an after-hours authorization process.[^2] Establish a clear protocol for these situations in advance.

These questions aren’t confrontational—they’re standard due diligence. A professional service provider will answer all five confidently and provide written confirmation of their policies. Hesitation or vague answers should prompt you to keep looking.

Since 1985, Drane Ranger has been providing grease trap cleaning services in Houston with complete, audit-ready documentation on every service. We understand that manifests aren’t paperwork—they’re protection.

Audit-Ready Binder Checklist

Use this checklist to verify your binder is inspection-ready:

Permit & Waivers

- [ ] Current FOG permit filed in Tab 1 (with renewal date noted)

- [ ] Permit posted copy clearly visible in facility

- [ ] Notice of Waiver filed in Tab 2 (if applicable)

Manifests (Past 5 Years)

- [ ] All manifests present and filed reverse chronologically

- [ ] Each manifest signed by driver

- [ ] Each manifest signed by your representative

- [ ] Each manifest stamped and signed by disposal facility

- [ ] Each manifest shows correct business name and address

- [ ] Service intervals meet 90-day requirement (or waiver on file)

Supporting Documentation

- [ ] Invoices/service reports filed in Tab 4

- [ ] Previous inspection reports filed in Tab 5

- [ ] Vendor credentials and contacts filed in Tab 6

Digital Backup

- [ ] All manifests scanned and filed with consistent naming

- [ ] Folder permissions set (one editor, multiple viewers)

- [ ] Backup updated within 24 hours of each service

- [ ] Last backup verification date: ___________

Review this checklist quarterly, ideally the week after your scheduled grease trap service. Regular verification means you’re always inspection-ready, not just scrambling when you hear the inspector is in your area.

Clean Isn’t Compliant Until It’s Documented

Many restaurant operators focus entirely on the physical cleaning—making sure the trap is pumped on time and the kitchen stays backup-free. That’s important, but it’s only half the equation. Houston’s environmental regulations require proof of legal disposal, not just proof that the grease disappeared from your property.

Cleaning removes waste. Manifests prove legal disposal. You need both to stay compliant and protected during inspections.

The Cheapest Pump-Out Can Be the Most Expensive

Price shopping for grease trap service makes sense—until it doesn’t. Some haulers offer dramatically lower prices by cutting corners on disposal and documentation. They might not use proper manifests, they might not be fully permitted, or they might take shortcuts that transfer liability directly to you.

When an inspector discovers improper disposal practices, they don’t just cite the hauler. As the waste generator, you’re responsible for ensuring your waste reaches an authorized disposal facility. Your real purchase isn’t just a pump-out—it’s audit-proof documentation that protects you if questions arise years later.

For a complete breakdown of how emergency situations compare to scheduled service, review why emergency pumping costs more than a contract.

Frequently Asked Questions

How long should we keep grease trap manifests in Houston?

Keep manifests for the past five years. Houston inspectors may request documentation going back this far during routine or complaint-driven inspections.[^1] Houston’s Code of Ordinances also addresses retaining the generator return copy for a five-year period and making it available upon request.[^5] While some operators keep records even longer, five years is the documented retention period you should plan for unless your specific permit states otherwise.

Is an invoice enough for a City of Houston audit?

No. An invoice proves payment, but a manifest proves legal disposal. These are distinct documents that serve different legal purposes. Many documentation failures occur when operators file only invoices, believing they’re protected, only to discover during an inspection that they have no proof their waste was disposed of legally. Always ensure you receive and file the complete manifest with all required signatures.

What makes a manifest invalid?

A manifest becomes invalid or weak protection if it’s missing critical elements: driver signature, generator representative signature, disposal facility stamp and signature, or proper business identifying information. Manifests with obvious after-the-fact additions or corrections may also raise questions. The manifest must create a complete chain of custody from your property to the authorized disposal facility.

What if the manager wasn’t on site to sign the manifest?

Establish a clear after-hours authorization protocol with your service provider before this situation occurs. Houston guidance addresses after-hours scenarios when there is no representative on-site to sign.[^2] Some restaurants designate backup signers who can be present during off-hours service. Others implement a verification call system where the driver contacts a manager by phone to confirm service and obtain verbal authorization, followed by signature upon the manager’s next shift. Document whatever protocol you choose and ensure your hauler understands and follows it consistently.

How often can an inspection happen—will we be notified?

Inspections in Houston may occur routinely or based on complaints, and you should not expect advance notification.[^1] The city’s program allows inspectors to verify compliance at any time during normal business hours. This means your documentation system needs to be inspection-ready every day, not just when you think an inspection might be coming. The best preparation is consistent compliance, not scrambling before anticipated visits.

From Inspection Anxiety to Audit Confidence

The scenario we opened with—the inspector waiting while you search for manifests—doesn’t have to be your reality. A simple binder system, consistent filing practices, and reliable documentation from your service provider transform inspections from panic-inducing events into routine verifications.

Your audit-ready system isn’t just about avoiding fines. It’s about operational peace of mind. When you know your documentation is complete and accessible, you can focus on running your restaurant instead of worrying about compliance gaps. That confidence extends to your managers, who can handle inspections professionally even when you’re not on site.

The restaurants that weather inspections successfully aren’t necessarily the ones with the newest equipment or the most expensive service contracts. They’re the ones with organized systems and reliable partners who deliver what they promise: complete, valid documentation on every service.

Want a vendor who hands you audit-ready paperwork every time? Call 281-489-1765 or request your quote. Drane Ranger has been serving Houston restaurants since 1985 with prompt, reliable service and documentation you can count on during inspections.

Our commitment is simple: thorough cleaning that meets Houston’s requirements, eco-friendly waste disposal practices, and the manifests that prove it—every single time. We serve the Greater Houston area, including Harris County, Fort Bend County, Montgomery County, Brazoria County, and Galveston County.

For more detailed information on preparing your kitchen for inspections or to learn about our full range of grease, grit, and lint trap services, visit our website or contact us during business hours (Monday through Friday, 9 AM until 6 PM) at 13911 India St, Houston, TX 77047.

Start Your Service Today – Call 281-489-1765

Disclaimer: This guide is for informational purposes and does not replace professional legal, environmental, or plumbing advice. Always follow your permit conditions and consult the City of Houston or your licensed service provider for requirements specific to your site.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our content. However, every article is thoroughly reviewed by expert humans on our Insights Team to ensure accuracy and clarity.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.

[^1]: Houston Permitting Center – Generator Registration at Food Establishment (HHD1017) https://www.houstonpermittingcenter.org/hhd1017

[^2]: Houston Health Department – Transporter Fact Sheet (PDF) https://www.houstonconsumer.org/media/11571/download?attachment=

[^3]: Houston Health Department – 2025 FOG Guide (PDF) https://www.houstonhealth.org/media/11616/download?attachment=

[^4]: TCEQ – Transporting Waste in Texas (Regulatory Guidance RG-86, PDF) https://www.tceq.texas.gov/downloads/permitting/waste-registration/pub/rg-086.pdf

[^5]: City of Houston Code of Ordinances (Municode) – Chapter 47 https://library.municode.com/tx/houston/codes/code_of_ordinances?nodeId=COOR_CH47WASE_ARTXITRTRCEWA_DIV9GETRDIWA_SD3TRDU