📌 Key Takeaways

A grease trap that looks clean from the sample well can still fail an inspection if the hidden sludge layer pushes total accumulation over 25%.

- Surface Checks Hide Compliance Risk: Visual inspection of the sample well only reveals the middle layer, completely missing the floating grease cap and bottom sludge that inspectors measure to determine compliance.

- The 25% Rule Is Performance-Based: When combined grease and sludge layers reach 25% of liquid depth, the trap’s effective working volume shrinks, allowing FOG to escape downstream—this performance threshold triggers required pump-outs regardless of appearance.

- Measurement Drives Smart Scheduling: Monthly core sampling with documented percentages enables service timing based on actual accumulation rates rather than arbitrary calendar intervals, preventing both premature pump-outs and costly violations.

- Manifests Prove Compliance: Cleaning records without signed waste manifests showing disposal facility and date leave restaurants vulnerable to fines during audits, even when traps are currently within limits.

- Documentation Creates Audit Confidence: A compliance binder combining core sampling logs, manifests, and photos transforms scattered paperwork into organized proof that satisfies Houston pretreatment inspections.

Core sampling turns guesswork into evidence—measure like an inspector, schedule by data, document everything.

Houston restaurant operators managing commercial kitchen compliance will find a practical framework here, preparing them for the step-by-step implementation guidance that follows.

Friday lunch rush. The health inspector walks into your Houston restaurant with a clipboard and a measuring rod. Your kitchen manager assures you the grease trap looks fine—after all, they checked the sample well just last week and the water looked clear. But when the inspector pulls a core sample, the news isn’t good. The combined grease cap and bottom sludge put you over the 25% threshold. You’ve failed, and now you’re facing violations, mandatory pump-outs, and potential fines.

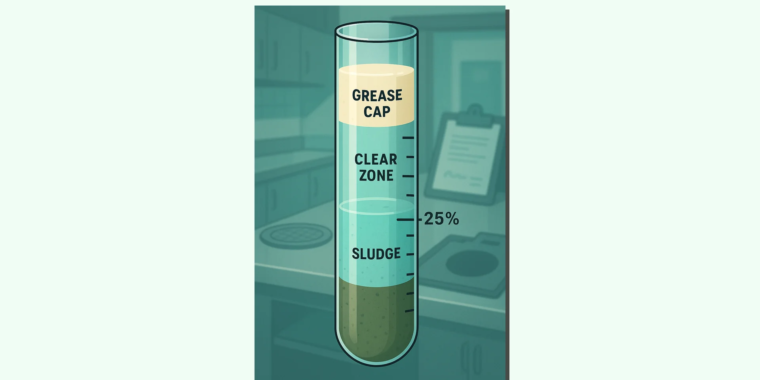

Here’s what happened: Visual checks only show you the surface. A core sample reveals the full story—the floating grease layer at the top and the settled solids at the bottom. Think of it like judging a latte by looking at the foam. You might see beautiful microfoam on top, but you have no idea how much heavy sediment has settled at the bottom of the cup. That hidden layer is exactly what gets restaurant operators into compliance trouble.

Core sampling isn’t just a best practice. It’s the inspector’s standard measurement method, and it’s the only way to know whether your trap is approaching Houston’s 25% accumulation limit (Source: City of Nacogdoches FOG Manual). When you rely on quick glances through the sample well, you’re essentially guessing. The practical application is straightforward: adopt monthly core sampling as part of your maintenance routine, schedule pump-outs when readings approach the threshold, and keep organized manifests that prove both the work and the legal disposal.

The “Eyeball Test” Problem—What Visual Checks Miss

Visual checks give you a false sense of security. When staff members peer into the sample well and see relatively clear water in the middle layer, they assume everything is fine. The problem is that grease floats and solids sink, creating a misleading “clean zone” in the middle that hides the real accumulation happening at both ends of the tank.

The top grease cap can be several inches thick but barely visible from above, especially if recent hot water from dishwashing has temporarily liquefied some of the fats. Meanwhile, the bottom sludge layer—a dense mix of food particles, oils, and settled solids—is completely invisible from a top-down view. This matters because when grease traps become overloaded, they can allow fats, oils, and grease to pass into the public sewer system, contributing to blockages and sanitary sewer overflows that wastewater agencies take very seriously (Source: EPA FOG Program Guidance).

Inspectors know this. That’s why they don’t trust visual assessments, and neither should you. The solution is simple: use a core sampler through the sample well to capture a complete vertical cross-section of your trap’s contents. This inexpensive tool (essentially a clear tube with a check valve) allows you to see and measure total accumulation—top grease plus bottom solids—in one reading. Document each measurement with the date, percentage, and staff initials, then schedule your next service based on those numbers rather than calendar dates alone.

What Inspectors Actually Measure

City inspectors and pretreatment personnel don’t guess. They follow a standardized protocol that involves taking a core sample at the sample well or inlet/outlet baffles, depending on your trap’s design. The measurement captures everything: the thickness of the floating grease layer, the depth of the clear middle zone, and the height of the settled solids at the bottom (Source: Houston Public Works FOG Program).

Here’s what matters for compliance: inspectors assess your trap’s performance by calculating total FOG (fats, oils, grease) accumulation as a percentage of the trap’s working volume. If that combined figure exceeds 25%, your trap has failed its performance standard, regardless of how recently it was cleaned or how clear the middle layer looks.

To mirror this method in your own maintenance checks, lower a core sampler to the tank bottom, capture the full column, then measure and record both the grease cap depth and the sludge depth. Calculate the percentage by adding those two measurements and dividing by total liquid depth. Log this reading in a simple notebook or tracking sheet, and you’ll be able to predict exactly when you need to schedule service—before an inspector shows up and finds you out of compliance.

The 25% Rule—When Your “Clean” Trap Isn’t Compliant

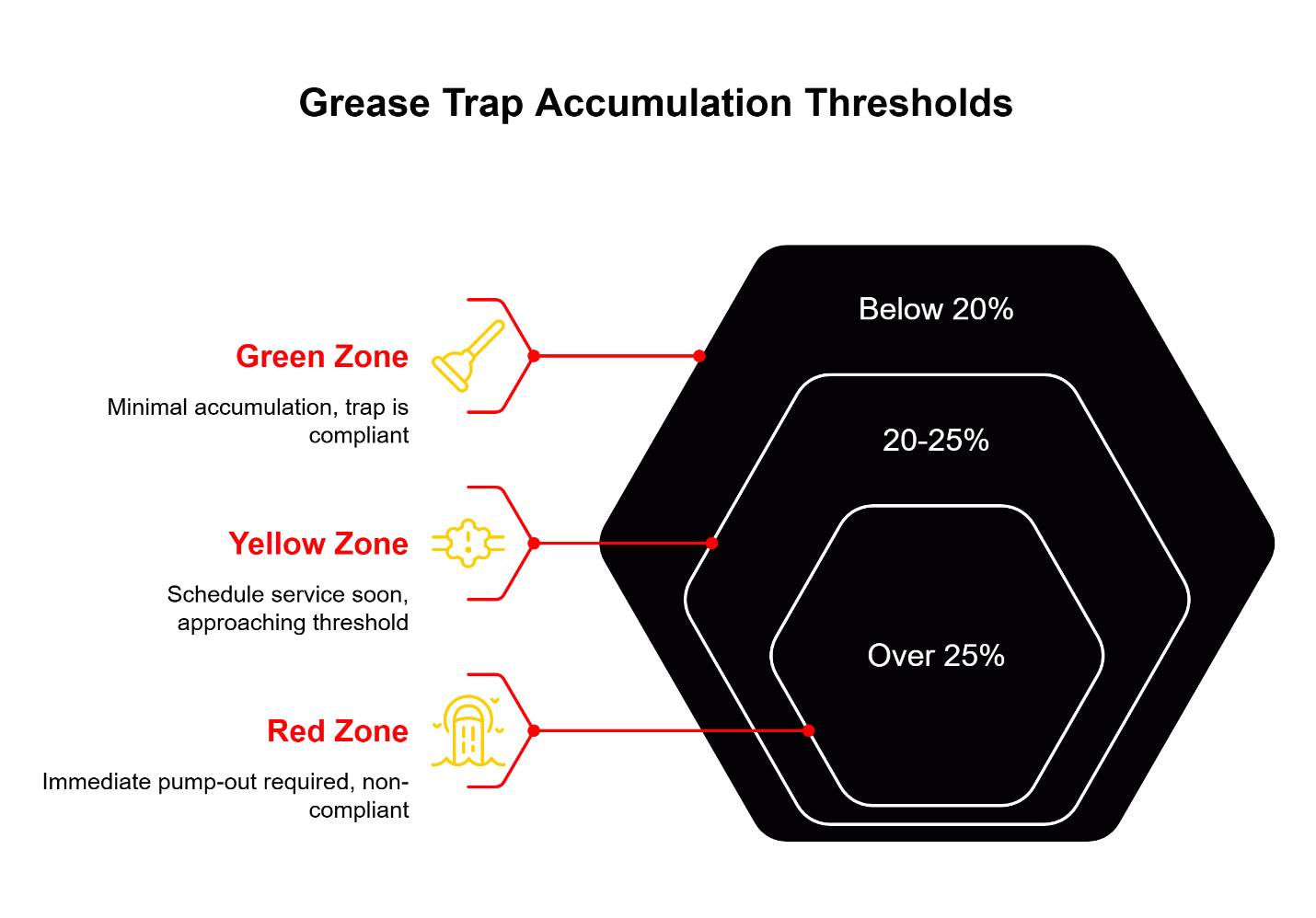

The 25% threshold isn’t arbitrary. It represents the point at which grease traps lose their effectiveness. When the combined thickness of floating grease and settled solids equals or exceeds 25% of the liquid depth, the trap’s effective working volume shrinks. Incoming wastewater has less time for FOG to separate properly, and more grease and solids can escape downstream into the public sewer system—exactly what the regulations are designed to prevent (Source: City of Nacogdoches FOG Manual).

What confuses many operators is that “25% full” doesn’t mean the trap looks obviously dirty. A busy kitchen can hit this threshold in as little as four to six weeks, especially during high-volume periods. The accumulation is happening continuously, but it’s hidden from casual observation. By the time you smell problems or notice slow drainage, you’re likely well past the compliance threshold and dealing with a more urgent—and expensive—situation.

Create a simple visual reference for your team: Green zone (below 20% accumulation), Yellow zone (20-25%, schedule service soon), and Red zone (over 25%, immediate pump-out required). Train kitchen managers to check monthly and to call for grease trap cleaning when readings move into the yellow zone. This proactive approach prevents emergency calls, compliance violations, and the operational disruptions that come with backed-up traps.

Step-by-Step: How to Take a Core Sample Through the Sample Well

Measuring your trap correctly takes about five minutes once you know the process. Here’s the sequence:

- Prepare safely. Put on gloves and safety glasses. Ensure adequate ventilation—grease traps produce hydrogen sulfide gas, which is both toxic and flammable. Clear the area of foot traffic and open nearby doors or activate exhaust fans.

- Access the sample well. Remove the sample well cover (typically a 4-inch PVC cap on top of the trap). If your trap doesn’t have a dedicated sample well, you’ll need to access through the main manhole, though this is less convenient for routine checks.

- Take the sample. Lower your core sampler (a clear graduated cylinder with a bottom check valve) straight down to the tank bottom. Once it touches, lift it smoothly to capture a complete column showing all three layers—grease cap, clear zone, and bottom sludge.

- Measure and record. Using the graduations on the sampler, measure the depth of the top grease layer and the bottom solids layer. Add these together, then divide by the total liquid depth to get your percentage. Write this in your log with the date and staff initials.

- Document with photos. Take a quick photo of the sampler with visible layers and the measurement. File this in your compliance binder alongside service manifests. If questioned during an audit, this photo proves you were monitoring conditions and taking appropriate action.

Compare today’s reading to your last measurement. If the percentage is climbing faster than expected, shorten your service interval rather than waiting for the next scheduled pump-out.

From Measurement to Paperwork—Passing the Audit

Cleaning your trap is only half of compliance. The other half is proving it happened—and proving the waste was disposed of legally. This is where many operators run into trouble, especially those who choose the cheapest available service to save a few dollars.

Every time your trap is pumped, you should receive a signed waste manifest showing the date, volume removed, hauler information, and most importantly, the disposal facility where the waste was taken. This manifest is your legal proof that FOG waste didn’t end up in a storm drain, vacant lot, or other illegal dumping site. Keep these documents organized in a dedicated compliance binder, along with your core sampling logs and any inspection reports.

Many municipal codes require restaurants to retain these manifests on site and make them available during inspections, often for a minimum of three years (Source: City of Dallas Code of Ordinances). Missing manifests can result in fines even if your trap is currently clean, because you can’t prove past compliance (Source: Municipal FOG Record-Keeping Guidance).

When evaluating grease trap cleaning in Houston, ask specifically about manifesting procedures and whether the company provides copies after every service. The few dollars saved with a bargain hauler aren’t worth the risk of using an unregistered operator who cuts corners on documentation.

Houston Reality Check—Why “Quarterly” Isn’t Always Enough

Within Houston city limits, restaurants are expected to maintain grease traps frequently enough to protect the public sewer system. In practice, quarterly pumping has become a common baseline interval for many facilities, but this is only a starting point. High-volume restaurants, facilities with undersized traps, or operations that use a lot of fryer oil often hit the 25% threshold well before 90 days.

This is why measurement-based scheduling makes more sense than calendar-based service. If your monthly core samples show you’re consistently reaching 20-22% by week eight, shortening your interval to every two months prevents violations and keeps your trap performing as designed. Conversely, lower-volume locations might find they can safely extend to every 14-16 weeks without exceeding the threshold.

Work with a service provider who understands this principle and bases recommendations on your specific accumulation rate rather than pushing everyone onto the same generic schedule. The right approach saves you money over time—you’re not pumping unnecessarily early, but you’re also not risking fines or backups by waiting too long.

Vendor Checklist: “Pit Crew” Criteria for Your Kitchen

Not all grease trap services are equal. When comparing providers, look for these markers of professionalism:

Trained and certified technicians who understand both the mechanical process and the regulatory requirements. The person pumping your trap should be able to explain the 25% rule and show you how to read a core sample.

Punctual and organized service that respects your business hours and cleans up thoroughly. Spills, lingering odors, or equipment left blocking your back door are signs of a careless operation.

Core sampling before and after service on request. Good operators measure before pumping to document your pre-service condition, then again afterward to confirm complete removal.

Manifesting every visit with copies provided automatically. You shouldn’t have to chase down paperwork. Disposal site information should be clearly noted on each manifest.

Proactive schedule management with advance reminders and suggested timing adjustments based on your accumulation trends. This partnership approach helps you stay ahead of compliance issues rather than reacting to emergencies.

Since 1985, our team has focused on delivering this level of service to Houston-area restaurants, backed by Better Business Bureau accreditation and a commitment to thorough documentation. The feedback we consistently hear is appreciation for the organized approach and the advance notice we provide for next cleaning dates.

Frequently Asked Questions

Is a clear sample well good enough to prove compliance?

No. A clear middle layer only shows you what’s happening in one narrow section of the trap. Inspectors require core sampling because it’s the only way to measure total accumulation including the hidden grease cap and bottom sludge.

Do I really have to keep copies of every manifest?

Yes. These documents are your legal proof of proper disposal. Many municipal FOG programs require restaurants to retain manifests and produce them during audits, often for three years or more. Missing paperwork can trigger violations even if your current trap condition is acceptable.

When should I actually call for service?

The safe answer is when your core sample readings approach or reach 20-25% accumulation. Don’t wait for odors or slow drainage—by that point, you’re likely already past the threshold and dealing with a more serious problem that could have been prevented with regular measurement.

Schedule Core Sample-Based Maintenance

Stop guessing and start measuring. Our team provides Houston restaurants with compliant grease trap cleaning backed by proper manifesting after every pump-out. We can set up a measurement-based maintenance schedule that keeps you ahead of the 25% threshold and audit-ready year-round.

Call us at 281-489-1765 (Monday through Friday, 9 AM to 6 PM) to schedule an initial assessment and receive a customized service plan based on your kitchen’s actual accumulation rate.

Visit us: 13911 India St, Houston, TX 77047

For more information about our full range of services, visit our contact page.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.