📌 Key Takeaways

Grease trap overflows disrupt operations and create compliance exposure, but a proactive maintenance system with proper documentation prevents repeat shutdowns.

- Symptom Stacks Signal Trouble Early: Persistent odors followed by slow drains indicate the trap is approaching capacity and needs service before backup occurs.

- Red Flags Require Immediate Action: Active floor overflow, water backing into prep sinks, or rapidly rising drains with strong odors demand stopping nonessential water use and calling emergency service immediately.

- Quarterly Schedules Often Fall Short: High-volume kitchens with fryers and griddles typically require service every six to eight weeks rather than the ninety-day regulatory minimum.

- Manifests Prove Compliance, Invoices Do Not: Inspectors require signed manifests showing waste custody and disposal facility stamps, not just payment receipts, to verify legal disposal.

- Prevention Costs Less Than Crisis: Systematic maintenance with audit-grade documentation prevents emergency service premiums, lost revenue during closure, and potential health code violations.

Invisible compliance means scheduled service that never disrupts the kitchen.

Independent restaurant operators and foodservice managers controlling maintenance decisions will gain immediate crisis response protocols and prevention frameworks, preparing them for the detailed implementation guidance that follows.

The dinner rush hits at 7:15 PM on a Friday. The kitchen is running at full capacity when the dishwasher calls out—water is backing up near the three-compartment sink. Within minutes, that unmistakable rancid odor reaches the dining room. Two customers at table seven exchange glances and ask for their check.

An overflow doesn’t announce itself politely. It arrives during your busiest shift, threatens to shut down operations, and leaves you facing health code violations alongside an expensive cleanup. This guide provides immediate containment steps for active overflows and a prevention system that eliminates repeat incidents.

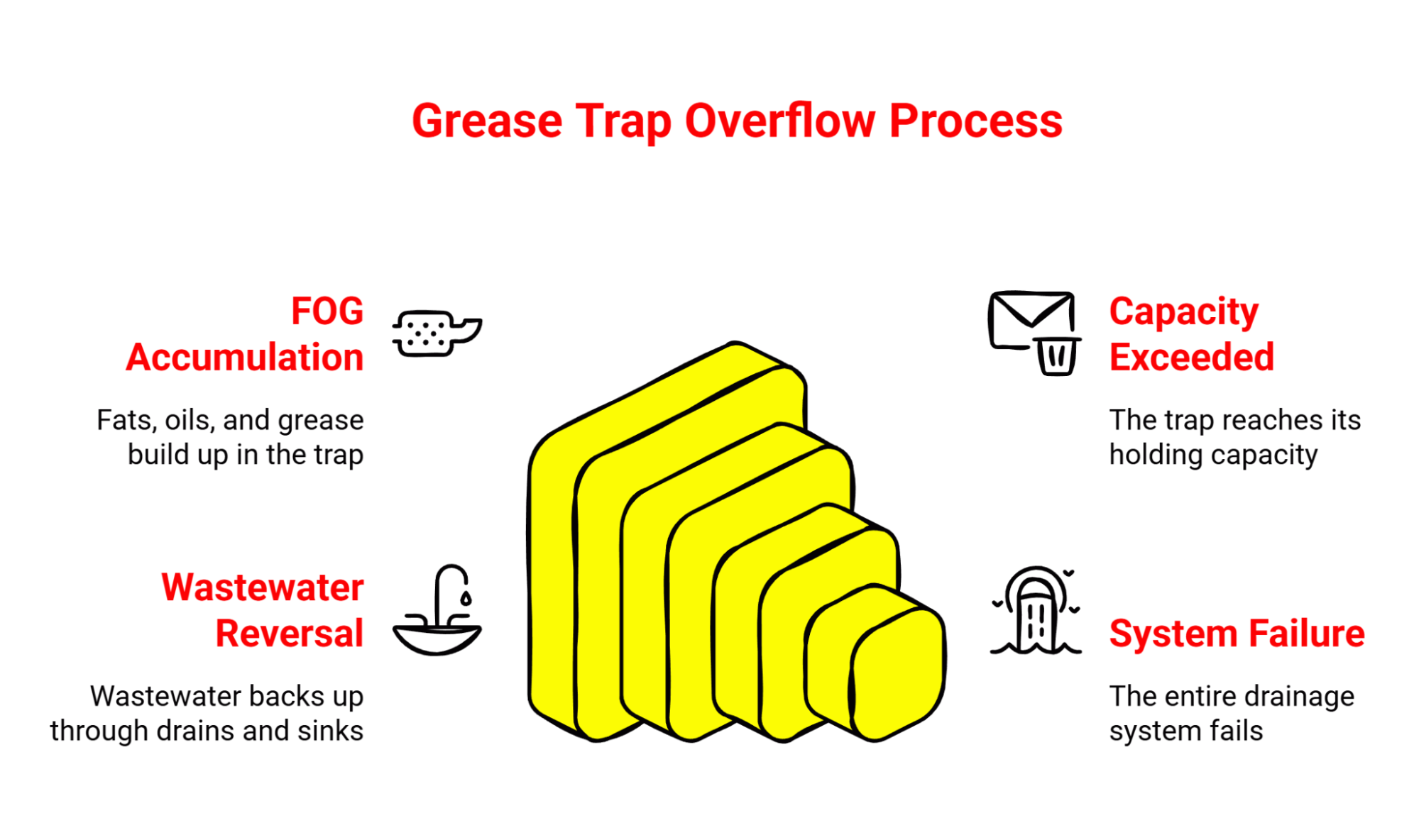

What a Grease Trap Overflow Actually Is

When accumulated fats, oils, and grease exceed a trap’s holding capacity, wastewater reverses course. Instead of flowing toward the municipal sewer system, it backs up through floor drains, prep sinks, and dishwashing stations. The trap functions as a filtration system—separating FOG from wastewater before discharge. Once that filter reaches capacity, the entire drainage system fails.

Consider a typical lunch service ending at a high-volume restaurant. Dishwashers scrape plates while prep cooks rinse cutting boards. All that water carries grease, food particles, and detergent toward a trap that has been 75% full since Tuesday morning. The system cannot process another gallon. Greasy water bubbles up through the floor drain, creating both a slip hazard and a contamination risk that forces immediate operational changes.

The trap itself performs a simple but essential function—it captures FOG before it enters public sewers, where it would congeal and create blockages affecting entire neighborhoods. For broader context on how FOG contributes to sanitary sewer overflows, the EPA’s FAQ on sanitary sewer systems explains the municipal infrastructure impacts. Professional commercial grease trap cleaning maintains this protective barrier on a schedule that matches each kitchen’s actual waste output.

The Backup Sequence

The physics of an overflow follow a predictable pattern. As FOG accumulates, usable capacity shrinks. Eventually, incoming wastewater has nowhere to go except backward through the path of least resistance.

Persistent rancid odors appear first, lingering near floor drains even after standard cleaning. Drainage slows next—sinks take longer to empty, and water pools where it previously flowed freely. These symptoms indicate the trap is approaching its limit. During peak water use—dinner rush, heavy dishwashing—the system reaches a breaking point. Heavy dishwashing during dinner service or back-to-back prep shifts generate more wastewater than the restricted trap can handle. Water backs up through floor drains, often carrying grease that spreads across kitchen floors.

This symptom progression—odor leading to slow drains, then backup, then overflow—tends to escalate fastest during high-volume periods because kitchens generate maximum FOG waste exactly when water flow peaks. A trap at 70% capacity on Monday morning can overflow by Friday evening’s rush.

When to Stop Operations: Severity Assessment

Understanding which situations require immediate action versus scheduled service helps operators make sound decisions under pressure.

RED—Stop Nonessential Water Use and Call Immediately

Active overflow on floors creates immediate slip and sanitation risks. Water backing up into sinks used for food prep or dishwashing compromises food safety. Rapidly rising floor drain water accompanied by strong odors signals system failure requiring emergency response.

YELLOW—Reduce Load and Schedule Urgent Service

Multiple drains slowing simultaneously indicates system-wide restriction. Intermittent gurgling or “burping” at floor drains suggests the trap is nearing capacity. Odors returning quickly after cleanup mean the underlying problem remains unresolved. These conditions warrant same-day service when possible.

GREEN—Schedule Service and Monitor

A single fixture draining slowly without odor or visible pooling may indicate a localized issue rather than trap failure. Absence of repeated symptoms or overflow suggests standard maintenance timing is appropriate.

This framework provides general operational guidance. Severity thresholds and reporting requirements vary by jurisdiction and individual facility risk profiles.

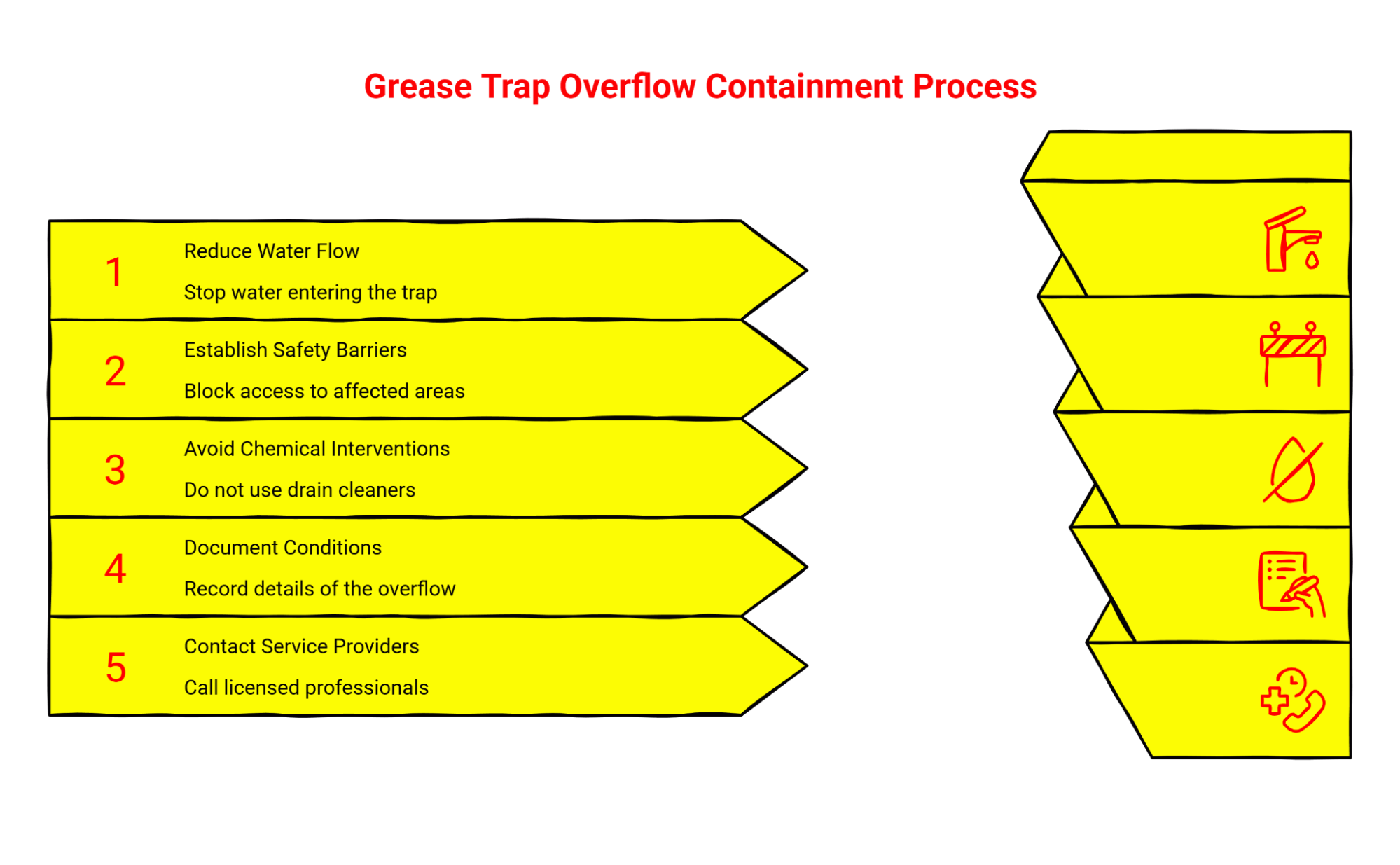

Immediate Containment Actions

Active backups require swift containment rather than attempted repairs. Professional resolution is necessary, but immediate steps minimize damage and protect both staff and customers.

Reduce water flow immediately. Stop dishwashing operations and shut off any equipment sending water toward affected drains. Additional water worsens the backup because the trap cannot accept more volume.

Establish safety barriers. Grease-contaminated wastewater creates slip hazards and introduces bacteria into work areas. Block access to affected zones and direct staff away from pooling water. If backup occurs near food preparation stations, cease using those areas until professional cleaning is complete.

Avoid chemical interventions. Drain cleaners cannot dissolve a trap filled with solidified grease. Introducing harsh chemicals or extremely hot water may damage trap components including baffles and seals. These products also create hazardous fumes when they react with standing wastewater.

Document conditions thoroughly. Record the time backup occurred, specific locations affected, observed symptoms, and severity. Note the most recent service date and provider if known. Photograph the situation if doing so is safe. This documentation supports your service provider’s diagnostic process and provides evidence for compliance records if inspectors inquire about maintenance gaps.

Contact licensed service providers. Overflow resolution requires vacuum truck capacity and proper waste disposal handling. For facilities operating inside Houston city limits, verify that your provider maintains registration with the city and can supply required manifesting documentation. Drane Ranger serves the Alvin area and surrounding communities with emergency response capabilities—call 281-489-1765.

Why Traps Reach Capacity

Overflows stem from predictable causes that facility managers can recognize and address before crises develop.

Inadequate service frequency tops the list. Many operations follow quarterly schedules because local regulations set 90-day intervals as minimums, not recommendations. Kitchens operating deep fryers, griddles, or high-turnover frying stations often generate FOG faster than quarterly service can accommodate. The trap fills between scheduled visits, leaving diminishing capacity that eventually proves insufficient.

Incomplete evacuation during previous service creates similar problems. Some providers extract only surface grease, leaving settled solids at the trap’s bottom. This approach provides short-term relief but fails to restore full capacity. Within weeks, symptoms return as FOG continues accumulating in an already-compromised trap. The sample well myth explains why visual inspection alone fails to detect this hidden accumulation.

Industry guidance establishes the 25% threshold as a critical decision point. When the combined depth of floating grease and settled solids reaches one quarter of the trap’s total liquid capacity, evacuation becomes necessary. Waiting for odors or slow drains means the threshold has passed and overflow risk escalates with each service day that follows. For detailed explanation of how this threshold applies in practice, see the 25% rule guide.

Downstream restrictions occasionally cause backups even when the trap itself maintains adequate capacity. Hardened grease in outlet lines creates partial blockages that prevent proper drainage. Damaged baffles allow FOG to pass through prematurely, defeating the trap’s separation function. These conditions require inspection and repair alongside standard pumping. Understanding why visual checks alone can miss these problems helps explain the value of thorough professional service.

Building a Prevention System

Repeat overflows indicate reactive maintenance patterns need replacement with proactive scheduling and documentation systems. The shift from crisis management to systematic compliance transforms trap service from an operational liability into background reliability—what operators call “invisible compliance.”

Match service frequency to actual volume. Track symptom appearance between scheduled services. Odors or slow drainage consistently emerging at week seven of a 90-day cycle signals inadequate frequency. The adjustment point is straightforward—when problems appear before the next scheduled service, increase frequency. Many high-volume facilities operate on six- to eight-week cycles rather than quarterly intervals. This adjustment prevents capacity issues before they develop into operational disruptions.

Integrate compliance documentation with every service visit. Every pump-out should generate records proving proper disposal through licensed facilities. This documentation functions as legal protection during inspections and audits. The distinction between invoices and manifests matters significantly here. An invoice confirms payment for service. A manifest tracks waste from your facility through transportation to an approved disposal location, including hauler registration information and facility verification stamps. Inspectors require manifests as proof of legal disposal, not invoices. Understanding the legal difference between manifesting and invoicing clarifies why proper documentation matters.

For operators managing extensive documentation requirements, systematic organization prevents inspection failures. Maintaining five years of signed manifests with disposal facility stamps, organized chronologically, transforms potential audit stress into straightforward verification. The investment in proper record-keeping provides protection worth far more than the administrative effort required. A complete guide to organizing grease trap documentation for city audits offers practical implementation steps.

For federal context on how FOG management programs are structured nationwide, the EPA’s Report to Congress on the Impacts and Control of CSOs and SSOs provides a comprehensive overview of permits, outreach, and enforcement approaches across jurisdictions.

Schedule services during operational low points. Proactive maintenance occurs on calendars rather than after crises force action. Services scheduled during slow periods minimize disruption while maintaining compliance. When trap maintenance operates as background reliability rather than emergency response, compliance stops generating stress and starts supporting smooth operations.

Prevention Checklist

Crisis Response (Part A)

Follow the immediate containment actions outlined above when facing active overflow.

Long-Term Prevention (Part B)

- Schedule service at frequency that prevents odor and slow-drain recurrence

- Standardize service expectations: complete evacuation plus site-ready documentation

- Track each service event in single organized system (digital or physical)

- Require consistent records showing service date, volume notes, and provider identifiers

- Review warning signs weekly: odor presence, drainage speed, peak-time performance

- Train staff on early warning signals and proper escalation procedures

- Escalate frequency when warning signs return before next planned visit

- Store documentation for retention period applicable in operating jurisdiction

Staff Response Protocol

Kitchen staff benefit from clear protocols for recognizing and escalating grease trap problems before they reach crisis level.

When floor drains back up or grease odors appear, staff should reduce water load immediately by pausing dish and mop sink operations as directed by management. Report the situation to the manager on duty, noting time and specific fixtures affected. Isolate hazards including wet floors and potential contamination zones. Do not attempt chemical fixes—focus on containment and proper escalation. Prepare a brief summary for the service provider covering symptoms observed, timeline of events, and any operational constraints affecting service timing.

This protocol empowers front-line staff to take appropriate immediate action while ensuring management receives timely notification for professional service arrangement.

Target Audience Alignment

This prevention approach serves independent restaurants, single-location foodservice operations, and commercial kitchens throughout Alvin and surrounding communities—facilities where owners, general managers, or operations managers control maintenance decisions directly and require audit-ready compliance systems.

The guidance provided addresses facilities outside Houston’s municipal boundaries. Operations inside Houston city limits must follow specific local FOG regulations including quarterly trap cleaning requirements and registered hauler mandates. The Houston Health Department’s Special Waste Permits page provides jurisdiction-specific requirements. For current enforcement details, consult municipal authorities or environmental compliance advisors familiar with your location. Additional context on Houston-specific requirements appears in the comprehensive FOG compliance guide.

This system does not address needs of multi-site corporate chains with centralized facilities management or residential properties equipped with small passive traps designed for minimal FOG generation.

The Hidden Cost of “Cheap” Service

Price comparison often reveals the lowest bid includes the narrowest scope. Budget providers extract visible surface grease, bypass settled solids, and deliver invoices without compliance documentation. This approach leaves traps with diminished capacity and operators without proof of legal disposal.

Vulnerability emerges when inspectors arrive requesting manifests that document proper waste handling. The cheap service suddenly becomes expensive liability because records cannot prove compliance. When traps overflow months early because settled solids remained, operators pay for emergency service, revenue loss during mandatory closure, and potential health code violations. Understanding the real cost of backup emergencies versus contracted maintenance clarifies the financial risk.

Audit-grade documentation and thorough service execution cost slightly more per visit but dramatically reduce exposure. The difference represents insurance against operational crises that cost multiples of service fees. Proper manifesting, complete evacuation including settled solids, and inspection of trap components and outlet lines provide protection worth far more than marginal price differences.

Harold R. described his experience: “My experience with Drane Ranger was a very organized, professional and on time experience. I was kept informed of what was happening and a suggested time of cleaning again. I will use them again and will definitely recommend them to anyone I speak with.”

Common Questions About Overflows and Prevention

What signals indicate an overflow is approaching?

Persistent rancid odors near floor drains or dishwashing areas provide the earliest warning, appearing even after thorough cleaning. Slower drainage follows—sinks empty gradually, and water pools longer than usual. The combination of both symptoms indicates capacity is nearly exhausted and service should occur before backup develops.

Should operations continue if drains are backing up?

When wastewater actively backs up into food preparation areas or creates floor pooling near cooking stations, affected operations must stop immediately. Contaminated water in prep zones creates health code violations and contamination risks that prevent safe food handling. Contain the affected area, document conditions, and arrange emergency service before resuming operations in those zones.

What causes most restaurant grease trap overflows?

Accumulation exceeding capacity because service intervals don’t match actual FOG output accounts for most failures. Kitchens running quarterly schedules often require more frequent service when they operate heavy FOG-generating equipment. Inadequate evacuation leaving settled solids behind and downstream line blockages preventing proper flow contribute as secondary causes.

How frequently should commercial traps receive service?

Kitchen volume determines optimal frequency. Jurisdictions often establish quarterly minimums, but operations with fryers, griddles, or heavy dishwashing commonly require service every six to eight weeks. The decision trigger is straightforward—when odors or slow drains appear consistently before scheduled service dates, increase frequency. The 25% accumulation threshold provides another clear indicator: when floating grease and settled solids combined reach 25% of trap depth, schedule evacuation regardless of time elapsed since the previous service.

What documentation proves compliance during inspections?

Signed manifests showing disposal facility verification stamps, service dates, waste volumes removed, and registered hauler information provide required proof. Store manifests alongside invoices but understand the distinction—invoices document financial transactions while manifests document waste custody from facility through approved disposal. Maintain service logs noting dates, providers, and trap conditions observed. Keep five years of records on-site for inspection access. This documentation package demonstrates compliance and helps evaluate whether current service frequency matches operational needs.

What information helps expedite emergency service calls?

Provide facility address, trap size if known, most recent service date, and current symptoms. For facilities operating under specific municipal FOG regulations, mention jurisdiction to confirm provider registration. Ask whether standard service includes manifest documentation and outlet line inspection. For routine scheduling rather than emergencies, offer preferred service windows that minimize operational disruption.

Next Steps

Shifting from reactive crisis management to scheduled compliance protects operations, simplifies regulatory requirements, and eliminates expensive emergency service calls. The investment in systematic maintenance costs less than a single overflow incident when accounting for emergency service premiums, lost revenue during closure, cleanup expenses, and potential violation penalties.

Professional Service Available Now

Drane Ranger serves Alvin and surrounding communities with reliable grease trap service backed by proper documentation. Whether addressing active emergencies or establishing prevention schedules, the team delivers expertise and compliance support that keeps kitchens operational.

Contact Drane Ranger

13911 India St, Houston, TX 77047

Phone: 281-489-1765

Hours: Monday–Friday, 9 AM–6 PM

Email: rwoods3719@aol.com

Response within 24 hours

Request service information or call directly to schedule.

Disclaimer: This article provides general educational information about grease trap overflows and maintenance. Requirements vary by jurisdiction, trap specifications, waste generation volume, and local enforcement practices. Consult qualified professionals and applicable authorities for guidance specific to your facility’s compliance needs.

By: The Drane Ranger Team

Since 1985, Drane Ranger has delivered professional liquid waste management throughout the Greater Houston area, specializing in grease trap service, septic systems, and FOG compliance support.