📌 Key Takeaways:

Avoid shutdowns by turning grease trap care into a predictable, documented routine.

Full Clean-Outs, Not Pump-Only: Removing liquids plus scraping/rinsing walls and baffles, followed by a manifest, prevents rapid re-clogs, odors, and surprise downtime.

Cadence You Can Trust: Start around 90 days and tighten for high volume, fry-heavy menus, or small traps to keep flow steady and inspections smooth.

Documentation = Protection: Keep every wastewater manifest on file to prove responsible haul-off and stay inspection-ready.

Choose Providers for Reliability: Demand written scope, full clean-outs, manifests every visit, and off-hours scheduling to avoid hidden costs and mid-service emergencies.

30-Day Plan Locks Habits: Baseline your setup, schedule service, train staff on daily FOG habits, set reminders, and confirm the next date to maintain momentum.

Predictable service + manifests + daily habits = open doors and a calm dinner rush.

When the dinner rush hits and your kitchen drains start backing up, every second counts. The acrid smell of grease mixed with wastewater can clear a dining room faster than a fire alarm. For Houston restaurant operators, this nightmare scenario represents more than just an unpleasant evening—it’s a direct threat to revenue, reputation, and regulatory standing.

Think of your grease trap system like the foundation of your building. Most of the time, it operates invisibly beneath the surface, handling the steady flow of fats, oils, and grease (FOG) that commercial kitchens inevitably produce. When that foundation fails, however, the entire operation comes to a grinding halt. Picture this: it’s 7 PM on a Friday night, your dining room is packed, and suddenly the kitchen sinks won’t drain. Orders back up, customers grow restless, and what should have been your biggest revenue night of the week transforms into a costly emergency.

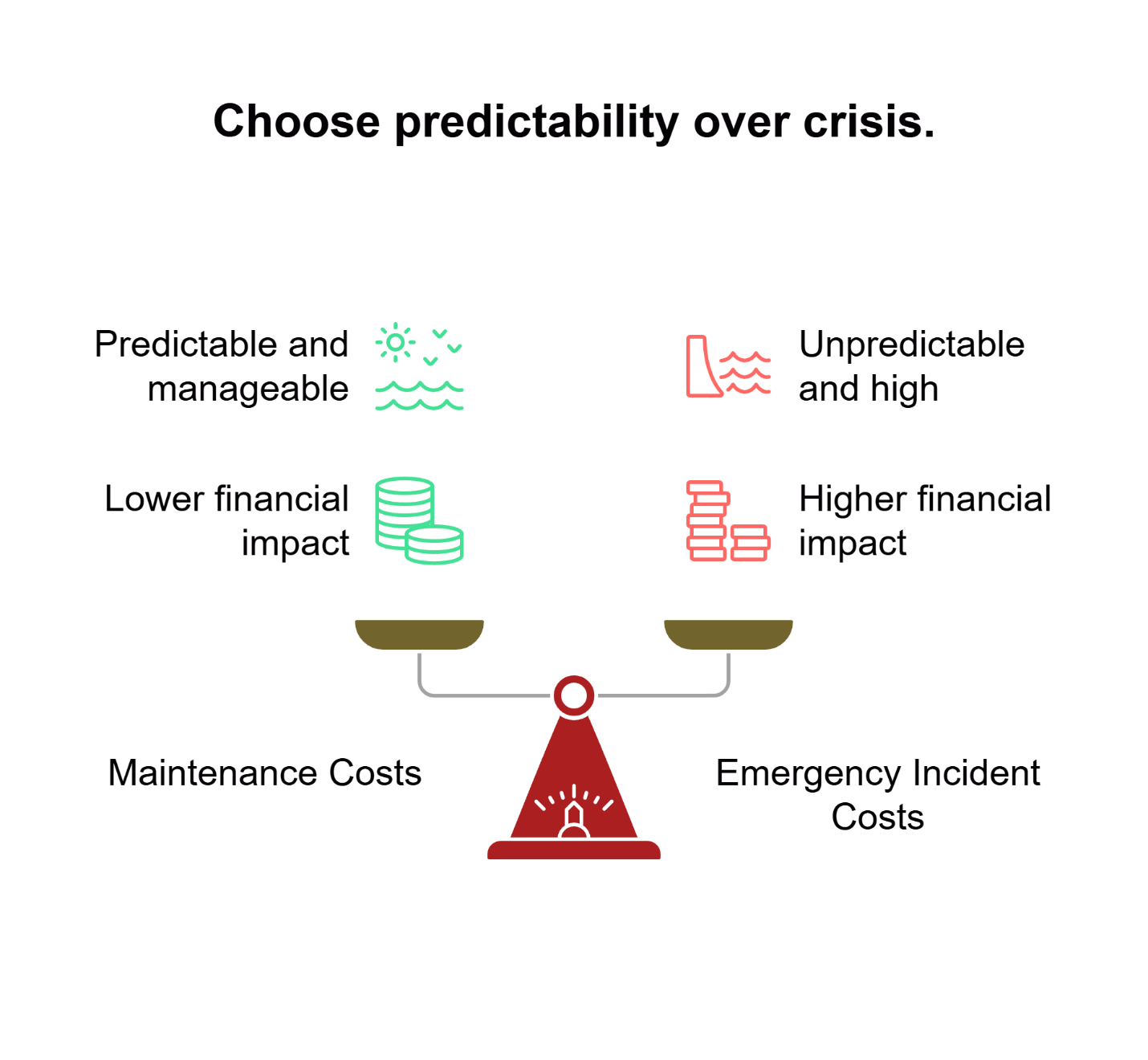

The solution lies in treating grease trap maintenance not as an afterthought, but as operational insurance. Professional grease trap service transforms this hidden risk into a predictable, manageable aspect of restaurant operations. Rather than waiting for problems to surface during your busiest moments, a structured approach to grease trap maintenance ensures your kitchen runs smoothly when it matters most.

What’s at Stake: Why Grease Trap Service Prevents Shutdowns in Houston

Restaurant shutdowns due to grease trap failures stem from a straightforward but potentially catastrophic process: FOG accumulation that blocks normal wastewater flow and creates backups throughout the kitchen drainage system.

How Backups Begin: FOG Accumulation Explained

The science behind grease trap problems is relatively simple, but the business consequences are severe. As cooking operations produce fats, oils, and grease, these substances flow into the grease trap where they’re designed to separate from wastewater. Over time, however, these materials solidify and accumulate. When the trap reaches capacity, FOG begins flowing into the main drainage system where it cools, hardens, and creates blockages.

The process accelerates during high-volume periods because increased cooking activity produces more FOG faster than the trap can effectively separate it. Many operators discover this timing creates a cruel irony: the busier and more successful the restaurant, the higher the risk of a grease-related shutdown during peak revenue periods.

The Business Math of Downtime: Revenue, Labor, and Reputation

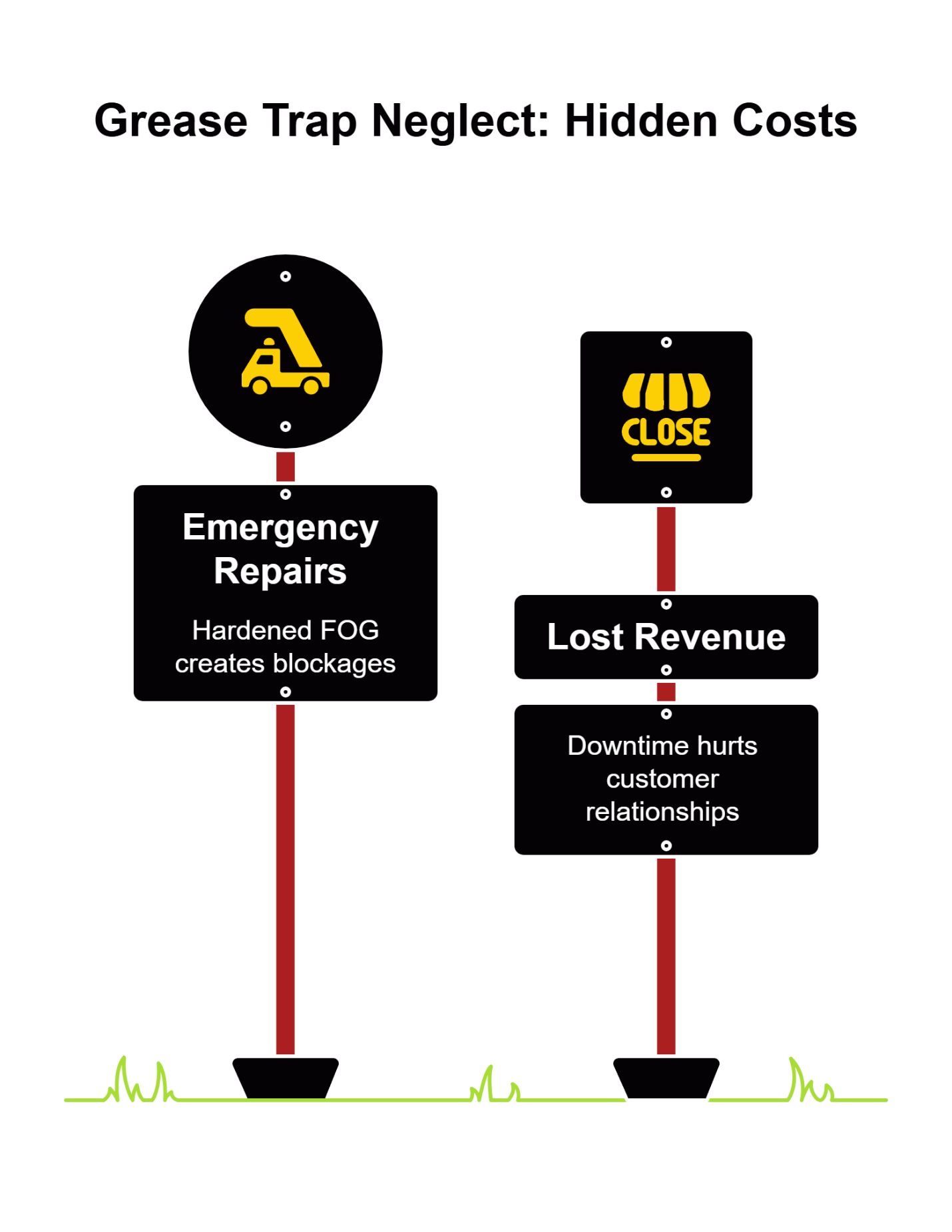

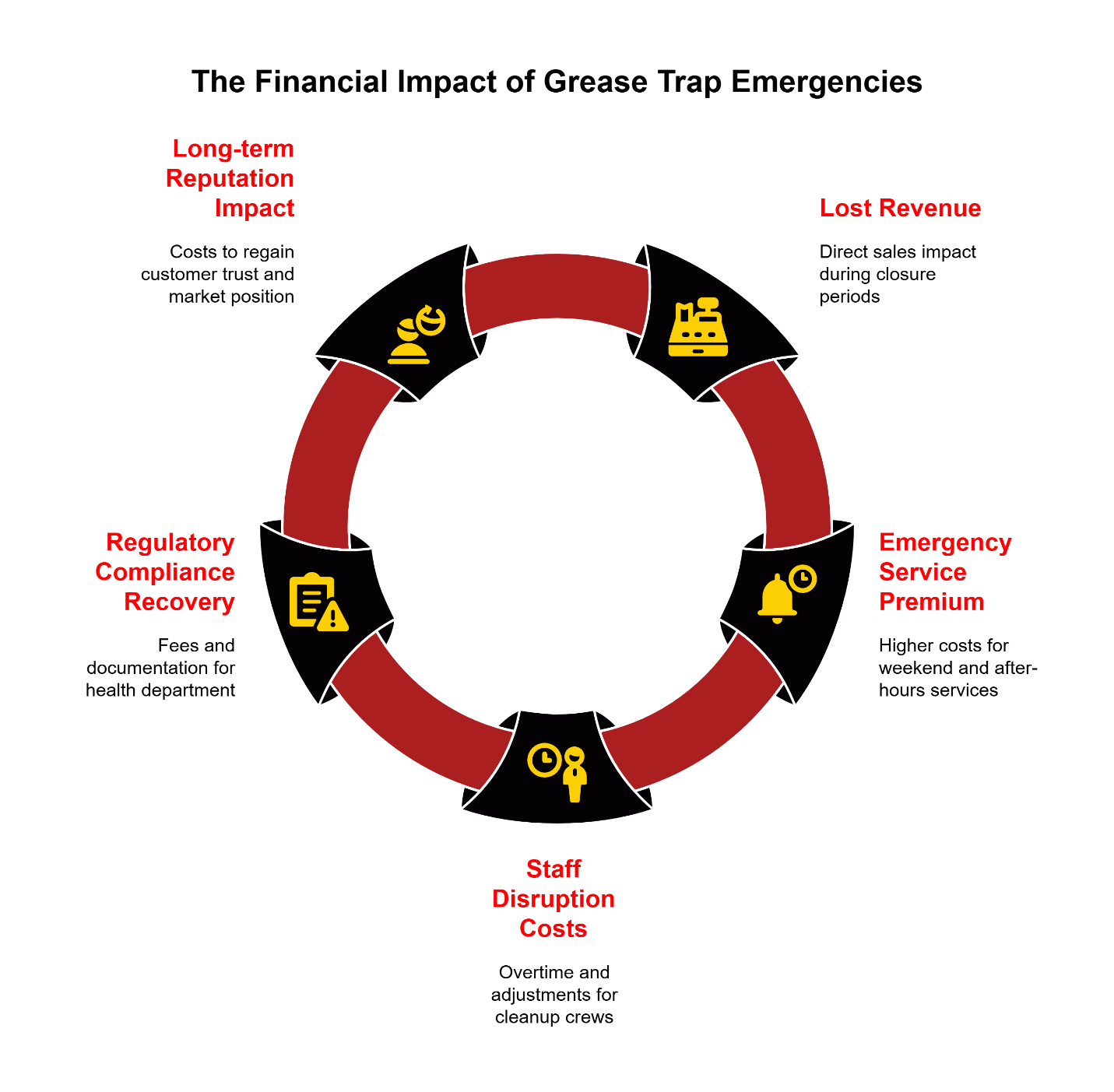

Consider the financial impact of a single evening shutdown during peak dining hours. A typical full-service restaurant averaging $1,000 per hour in revenue during prime time faces immediate losses that extend far beyond the evening’s sales.

Direct Revenue Loss: A four-hour Friday night shutdown equals $4,000 in immediate lost sales. Weekend closures compound this impact because these represent the highest-margin hours of the week.

Labor Costs Continue: Kitchen and service staff still require payment despite the inability to serve customers. Food prep completed before the shutdown often requires disposal, adding waste costs to labor expenses.

Reputation and Customer Relationships: Perhaps most damaging, customers turned away due to operational failures rarely return immediately. Social media amplifies negative experiences, and recovery requires months of consistent positive service to rebuild damaged reputation.

Emergency Service Premiums: Grease trap failures that occur during peak hours require emergency service calls, typically costing 200-300% more than scheduled maintenance visits.

Quick Definition: What Counts as Professional Grease Trap Service

Professional grease trap service encompasses a complete cleaning process that includes pump-out, physical cleaning, and proper documentation—not simply removing accumulated liquids.

The distinction between basic pump-out and comprehensive service determines whether the maintenance actually prevents future problems. A pump-out removes liquid waste but leaves solidified FOG adhering to trap walls and baffles. This residual buildup accelerates reaccumulation, shortening the effective interval between service calls and increasing the likelihood of operational disruptions.

Pump-Out vs. True Clean-Out: Why the Difference Matters

A complete clean-out process involves several critical steps beyond liquid removal. After pumping out accumulated waste, technicians perform a thorough scrape-down of all internal surfaces, removing hardened FOG deposits that standard pumping cannot address. This physical cleaning process followed by a high-pressure rinse ensures the trap returns to optimal operating condition.

The business impact of this distinction becomes apparent over time. Restaurants relying on pump-only service typically require more frequent visits and experience higher rates of emergency calls due to incomplete cleaning. Complete clean-out service, while requiring slightly more time per visit, extends effective intervals between services and significantly reduces emergency situations.

Documentation and Manifests: What They Are and Why They’re Kept

Professional service includes comprehensive documentation through waste manifests—official records tracking the collection, transportation, and disposal of removed waste. These documents serve multiple critical functions for restaurant operations.

Manifests provide concrete evidence of proper waste handling during regulatory inspections. Houston’s FOG compliance requirements include documentation standards, and manifests demonstrate adherence to proper disposal protocols. Additionally, these records help operators track service intervals and identify patterns that might indicate needed adjustments to cleaning frequency.

The documentation process also protects restaurants from liability issues related to waste disposal. Professional service providers handle all regulatory requirements for waste transportation and processing, but manifests provide restaurants with proof that waste left their facility through proper channels.

Houston’s Rulebook in Plain English (Zero Legal Jargon)

Houston requires regular grease trap maintenance and proper documentation as part of the city’s FOG management program, designed to protect the municipal wastewater system from blockages that can cause environmental damage and infrastructure problems.

The basic requirements center on two main principles: regular cleaning intervals and proper record-keeping. While specific requirements can vary based on factors like restaurant size, trap capacity, and operational volume, most establishments follow quarterly cleaning schedules as a baseline. However, restaurants should consult current city guidelines and work with qualified service providers to ensure compliance with all applicable regulations.

Why These Rules Exist: Houston’s FOG ordinance addresses real infrastructure challenges. When grease enters the municipal sewer system, it causes blockages that can result in sewage overflows, environmental contamination, and expensive repairs to public infrastructure. Restaurant compliance helps prevent these community-wide problems while protecting individual businesses from operational disruptions.

Professional service providers help restaurants navigate compliance requirements by maintaining proper manifests, following approved disposal methods, and providing documentation that demonstrates adherence to regulatory standards. This collaborative approach allows restaurant operators to focus on their core business while ensuring regulatory obligations are met through professional expertise.

Set the Right Cadence: Building a Reliable Service Schedule

Most Houston restaurants establish a baseline service interval of approximately 90 days, then adjust this schedule based on operational factors that affect FOG production and accumulation rates.

The 90-day baseline provides a starting point for most operations, but several factors typically require schedule adjustments. High-volume restaurants, establishments with extensive fried food menus, and operations using smaller grease traps often benefit from shorter intervals. Conversely, restaurants with limited frying, smaller daily covers, or larger trap systems might extend intervals slightly while maintaining effective FOG management.

Common Baselines and When to Shorten

Volume Considerations: Restaurants serving more than 200 covers daily typically require more frequent service due to the sheer quantity of FOG production. Peak season operations, such as those in tourist areas, may need temporary schedule adjustments during high-volume periods.

Menu Impact: Establishments specializing in fried foods, particularly those using solid cooking fats, generate FOG that solidifies more quickly in trap systems. These operations often benefit from 60-75 day intervals rather than the standard 90-day baseline.

Trap Size Relationships: Smaller grease traps reach capacity more quickly, requiring more frequent attention. Restaurants with trap systems below 500-gallon capacity typically need service every 60-90 days, while larger systems may effectively operate on 90-120 day intervals.

Volume, Menu, and Trap Size: Three Drivers of Frequency

| Restaurant Profile |

Typical Interval |

Key Factors |

| High-volume fried food |

60-75 days |

Daily covers >200, extensive frying |

| Standard full-service |

90 days |

Mixed menu, moderate frying |

| Low-volume/limited frying |

90-120 days |

<100 daily covers, minimal fried items |

These intervals serve as starting points for service scheduling. Operators should work with their service provider to monitor trap conditions and adjust frequency based on actual accumulation patterns observed during service visits.

Inside the Visit: A 5-Step Service Breakdown

Professional grease trap service follows a systematic process designed to restore optimal trap function while ensuring safety and regulatory compliance throughout the procedure.

Understanding this process helps restaurant operators prepare effectively and recognize quality service. Each step serves specific purposes in maintaining trap effectiveness and preventing operational disruptions.

Step 1: Arrival and Safety Prep

Professional technicians begin each service call with safety preparation and site assessment. This includes reviewing access routes, confirming the service window doesn’t conflict with peak kitchen operations, and establishing communication with designated restaurant staff.

Safety protocols require proper ventilation of the trap area, as accumulated FOG can produce hazardous gases. Technicians use gas detection equipment and ensure adequate airflow before beginning work. This preparation phase typically requires 10-15 minutes but prevents dangerous conditions during the service process.

Step 2: Complete Pump-Out

The pump-out process removes all liquid waste from the trap system using specialized vacuum equipment. Professional service includes removing waste from all chambers and ensuring complete liquid extraction before proceeding to physical cleaning phases.

During pump-out, technicians assess the quantity and consistency of removed waste. This evaluation helps determine whether the service interval is appropriate for the establishment’s FOG production patterns. Excessive solid accumulation might indicate the need for more frequent service, while minimal buildup could suggest interval extension possibilities.

Step 3: Scrape-Down and Rinse

Physical cleaning removes solidified FOG deposits that pump-out cannot address. Technicians use specialized tools to scrape accumulated grease from trap walls, baffles, and other internal components. This step distinguishes professional service from simple pump-out procedures.

The scrape-down process typically reveals the trap’s actual condition and effectiveness. Heavy buildup on internal surfaces indicates either inadequate service intervals or potential operational changes that increase FOG production. Following physical cleaning, high-pressure rinsing removes loosened debris and restores proper flow patterns through the system.

Step 4: Visual Check and Notes

Comprehensive inspection identifies potential maintenance needs and operational concerns that could affect future trap performance. Technicians examine structural integrity, inlet and outlet conditions, and overall system function.

This inspection phase often identifies minor issues before they become major problems. Damaged baffles, improper water levels, or unusual wear patterns can indicate needed repairs or operational adjustments. Addressing these concerns during routine service prevents emergency failures and extends overall system life.

Step 5: Manifests, Haul-Off, and Disposal

Professional service concludes with proper documentation and waste disposal through approved facilities. Manifests detail the quantity and type of waste removed, transportation information, and final disposal location.

The documentation process provides restaurants with records demonstrating regulatory compliance and proper waste handling. These manifests become part of the restaurant’s compliance file and serve as evidence of appropriate waste management during inspections or audits.

Provider Selection Checklist: How to Avoid Hidden Costs

Selecting a grease trap service provider requires evaluating factors beyond initial pricing to ensure comprehensive service and avoid unexpected expenses that can exceed initial savings.

Many operators focus primarily on service pricing without considering the total cost of ownership, which includes emergency calls, compliance risks, and operational disruptions caused by inadequate service. A structured evaluation process helps identify providers who deliver genuine value through comprehensive service and reliability.

Proof of Proper Disposal and Manifests

Legitimate service providers maintain all required permits and insurance for waste transportation and disposal. They provide detailed manifests after each service visit and can demonstrate relationships with approved disposal facilities.

Operators should verify that potential providers can show current permits, insurance certificates, and waste disposal facility agreements. Providers unable or unwilling to provide this documentation may create compliance risks for restaurants, potentially resulting in regulatory violations and associated penalties.

Scheduling Reliability and After-Hours Options

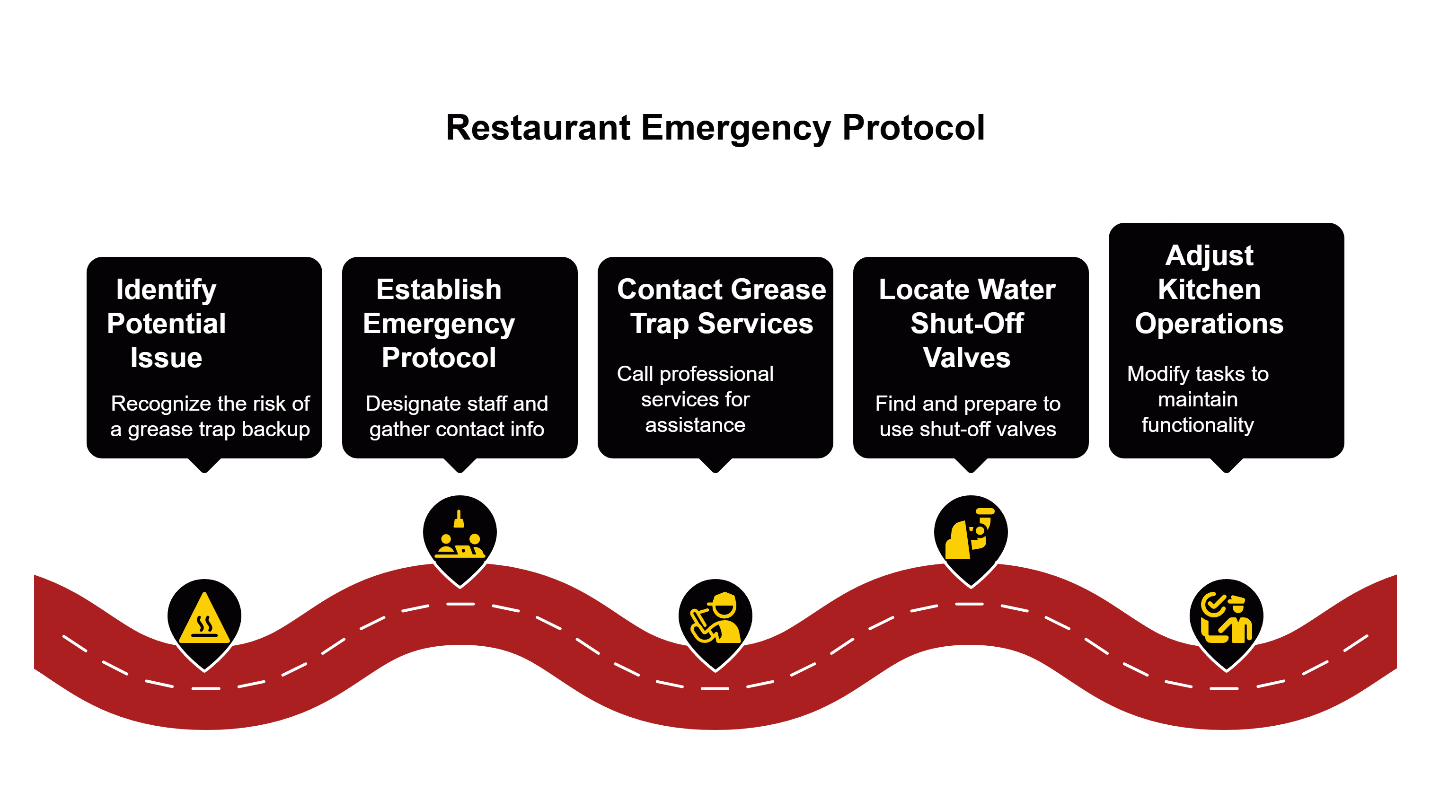

Consistent service scheduling prevents emergency situations that disrupt operations and cost significantly more than routine maintenance. Reliable providers offer predictable scheduling, advance notification of service visits, and emergency response capabilities for unexpected problems.

After-hours service availability becomes critical when problems occur during peak operating periods. Providers offering 24-hour emergency response help minimize revenue loss from operational disruptions, though emergency rates typically cost 2-3 times standard service pricing.

Transparent Scope: No ‘Pump-Only’ Surprises

Service agreements should clearly specify what’s included in routine visits to avoid disputes and unexpected charges. Comprehensive service includes pump-out, physical cleaning, documentation, and basic system inspection as standard procedure.

Red Flags to Avoid: Providers offering significantly below-market pricing often exclude essential service components, resulting in hidden costs and inadequate cleaning. Common exclusions include physical cleaning, manifest preparation, or disposal fees presented as separate charges after service completion.

Quality Indicators: Professional providers clearly explain their service process, provide written service agreements detailing included work, and maintain consistent pricing without surprise add-ons. They also demonstrate knowledge of local regulations and compliance requirements relevant to restaurant operations.

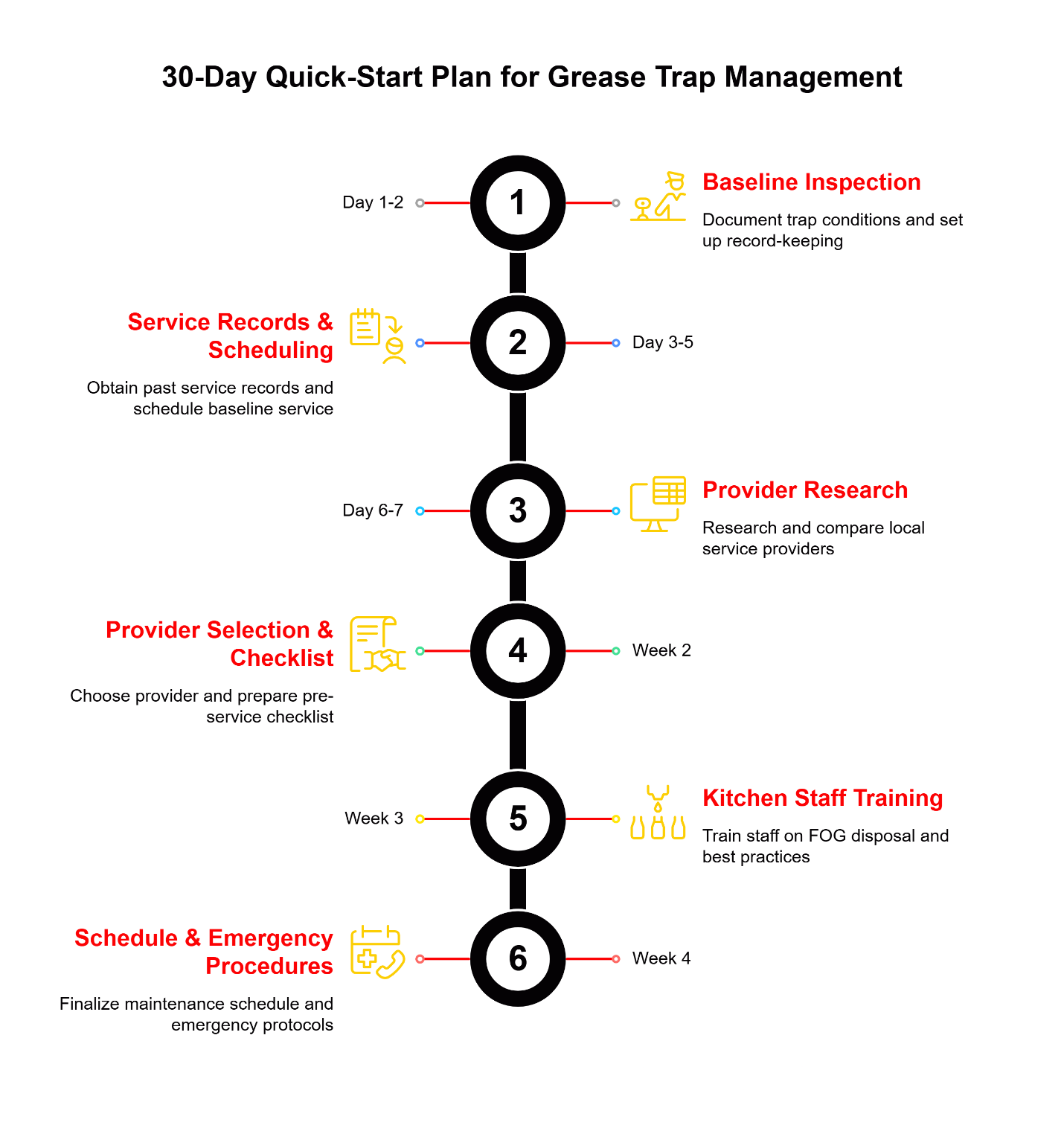

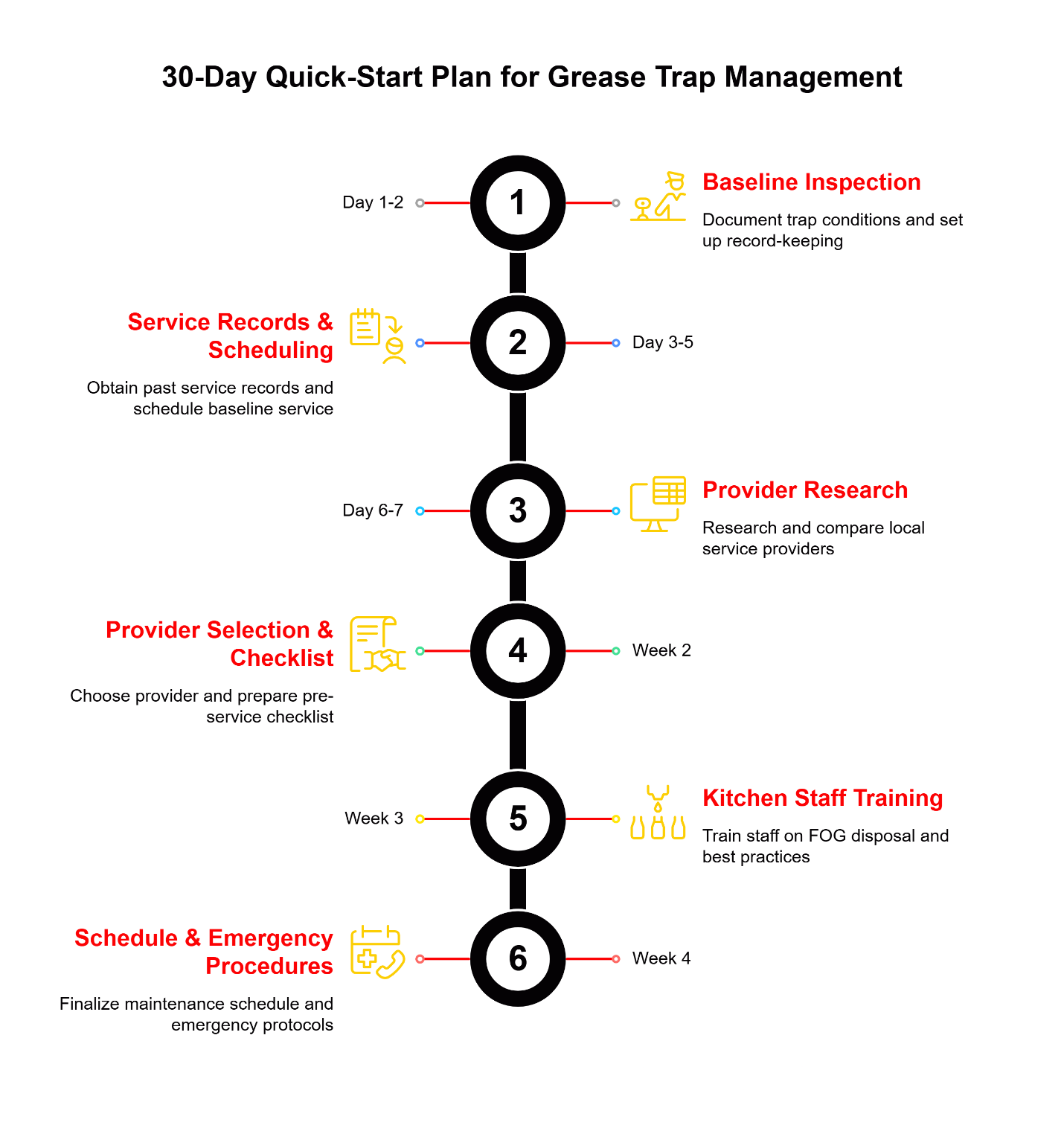

30-Day Quick-Start Plan for Houston Operators

Implementing effective grease trap management requires systematic preparation and team coordination. This structured approach helps restaurants establish reliable maintenance routines while avoiding common implementation mistakes.

The four-week timeline allows gradual implementation without overwhelming daily operations while ensuring all necessary components are properly established before relying on the new maintenance schedule.

Week 1: Baseline Inspection and Manifest File Setup

Begin by documenting current trap conditions and establishing record-keeping systems that will support ongoing compliance and maintenance tracking.

Day 1-2: Locate and photograph your grease trap system, noting trap size, access points, and last service date if available. Create a simple file (physical or digital) for storing service manifests and maintenance records.

Day 3-5: Contact your current service provider (if applicable) to obtain copies of recent manifests and service records. If no recent service has occurred, schedule an immediate baseline service to establish trap condition and appropriate service intervals.

Day 6-7: Research local service providers and request quotes that specify complete service scope, including pump-out, cleaning, and documentation. Compare not just pricing but service components and emergency availability.

Week 2: Book Service and Align Pre-Service Checklist

Establish service relationships and prepare operational procedures that minimize disruption during maintenance visits.

Service Provider Selection: Choose a provider based on comprehensive service offering, manifest provision, and scheduling reliability rather than lowest price alone. Confirm emergency service availability and response times.

Pre-Service Preparation: Develop a simple checklist for service days including access clearance, timing coordination, and staff communication protocols. Designate a point person for service provider coordination to ensure consistent communication.

Week 3: Train Team on Daily FOG Habits

Implement kitchen practices that reduce FOG accumulation and extend service intervals while maintaining food quality and operational efficiency.

Kitchen Staff Training: Review proper disposal procedures for cooking oil, food scraps, and cleaning materials. Emphasize that small daily habits significantly impact trap performance and service frequency requirements.

Practical Measures: Install grease collection containers for used cooking oil, provide scrapers for plate cleaning before washing, and establish protocols for disposing of oil-heavy food waste. These simple measures can extend service intervals and reduce emergency calls.

Week 4: Review Schedule and Phone-Tree for Issues

Finalize ongoing maintenance schedules and establish communication procedures for addressing problems before they become operational emergencies.

Schedule Confirmation: Confirm recurring service appointments with your chosen provider and add these dates to restaurant calendars with prep reminders. Establish procedures for rescheduling service when conflicts arise with special events or peak periods.

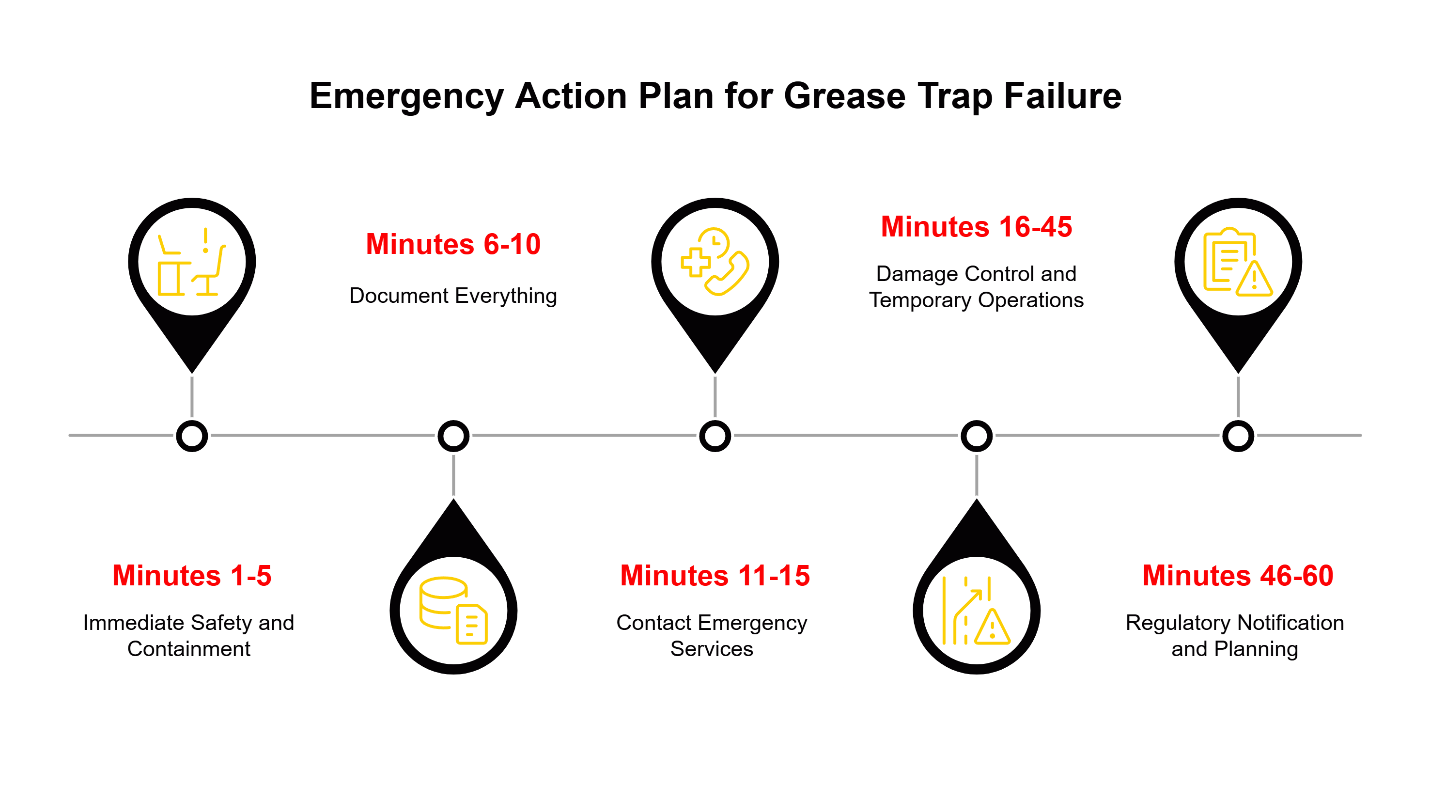

Emergency Procedures: Create contact information for after-hours service and establish decision protocols for determining when emergency service is necessary versus manageable until the next scheduled visit.

Pre-Service Kitchen Prep Checklist

Service Day Preparation

- Clear access path to grease trap location

- Confirm service timing avoids peak kitchen operations

- Designate staff member as service provider contact

- Prepare manifest filing system for new documentation

Provider Selection Mini-Checklist

Essential Service Components

- Complete pump-out and physical scrape-down included

- Written manifests provided after each visit

- Transparent pricing with no hidden disposal fees

- Emergency service availability with clear rates

FAQ: Straight Answers for Busy Managers

How often should Houston restaurants clean their grease traps?

Most restaurants start with 90-day intervals and adjust based on volume, menu, and trap size. High-volume operations with extensive fried food menus typically require 60-75 day intervals, while smaller operations might extend to 120 days. Your service provider can help determine the optimal frequency based on actual trap conditions observed during visits.

Does cleaning automatically mean compliance?

Regular cleaning is essential for compliance, but restaurants also need proper documentation through manifests and records demonstrating appropriate disposal. Professional service providers help maintain compliance by following proper procedures and providing necessary documentation, but restaurants should understand their role in maintaining records and scheduling appropriate service intervals.

What’s included in a professional service visit?

Complete service includes pump-out of all liquids, physical scraping of solidified deposits, high-pressure rinsing, basic system inspection, and manifest documentation. This comprehensive approach differs from simple pump-out services that may leave residual buildup contributing to faster reaccumulation.

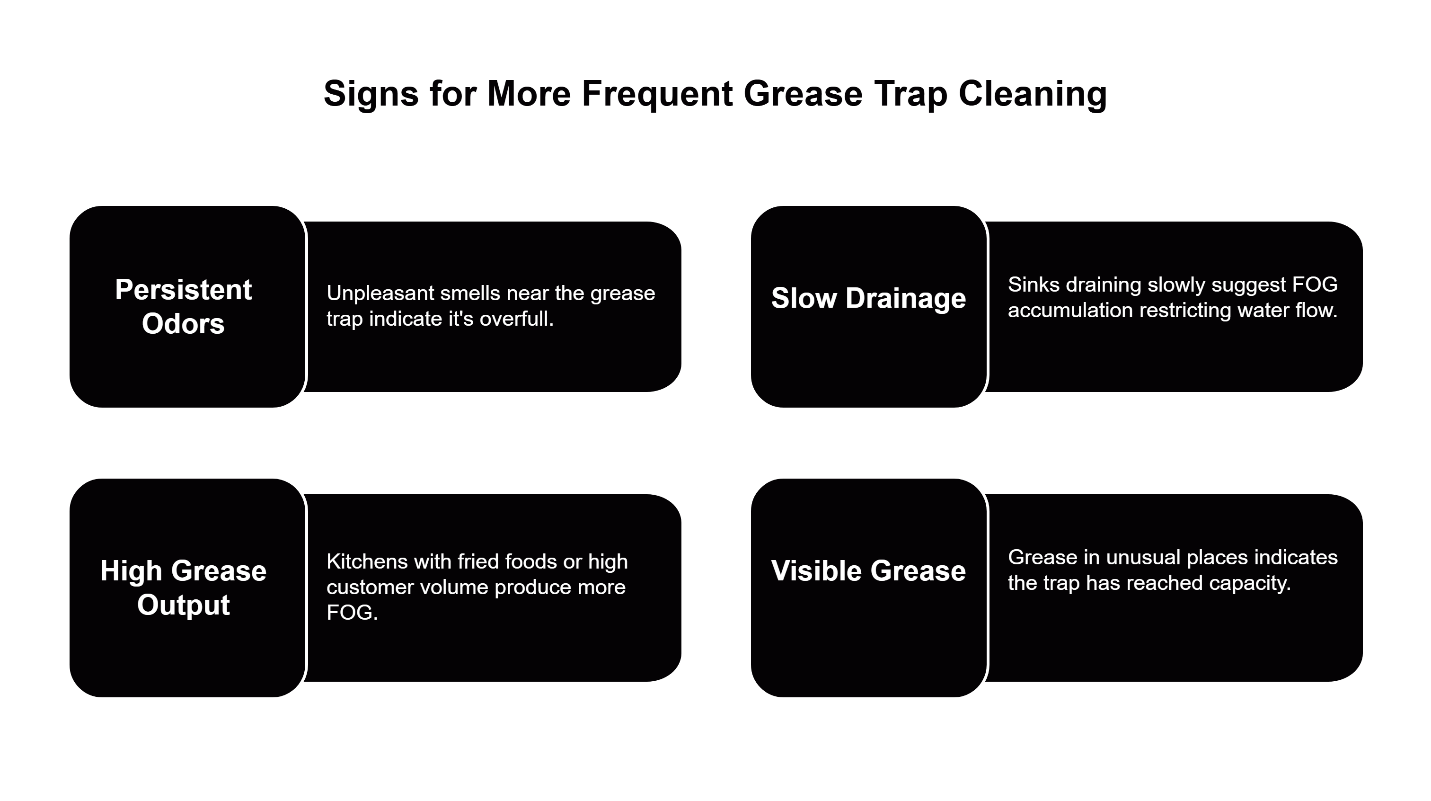

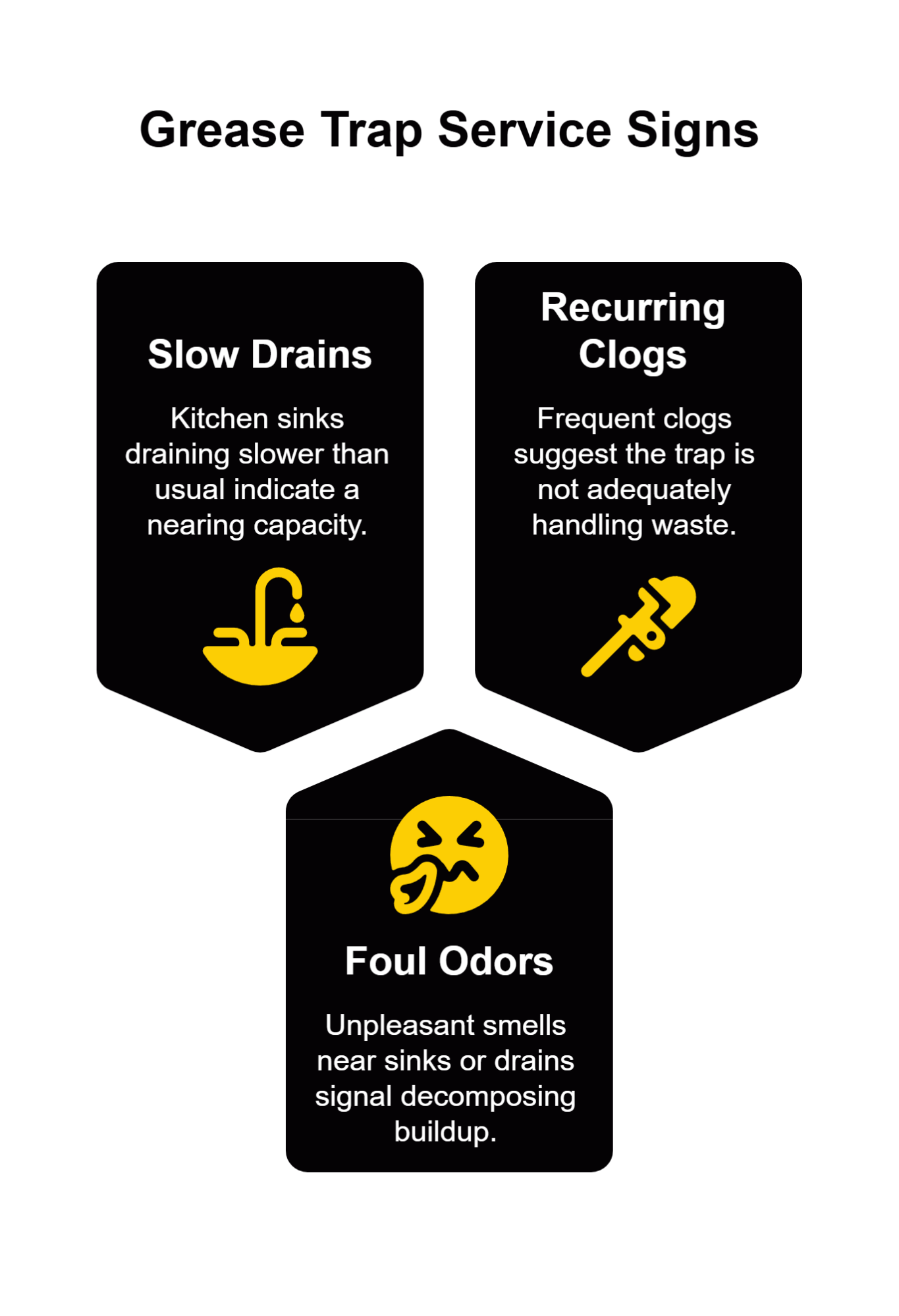

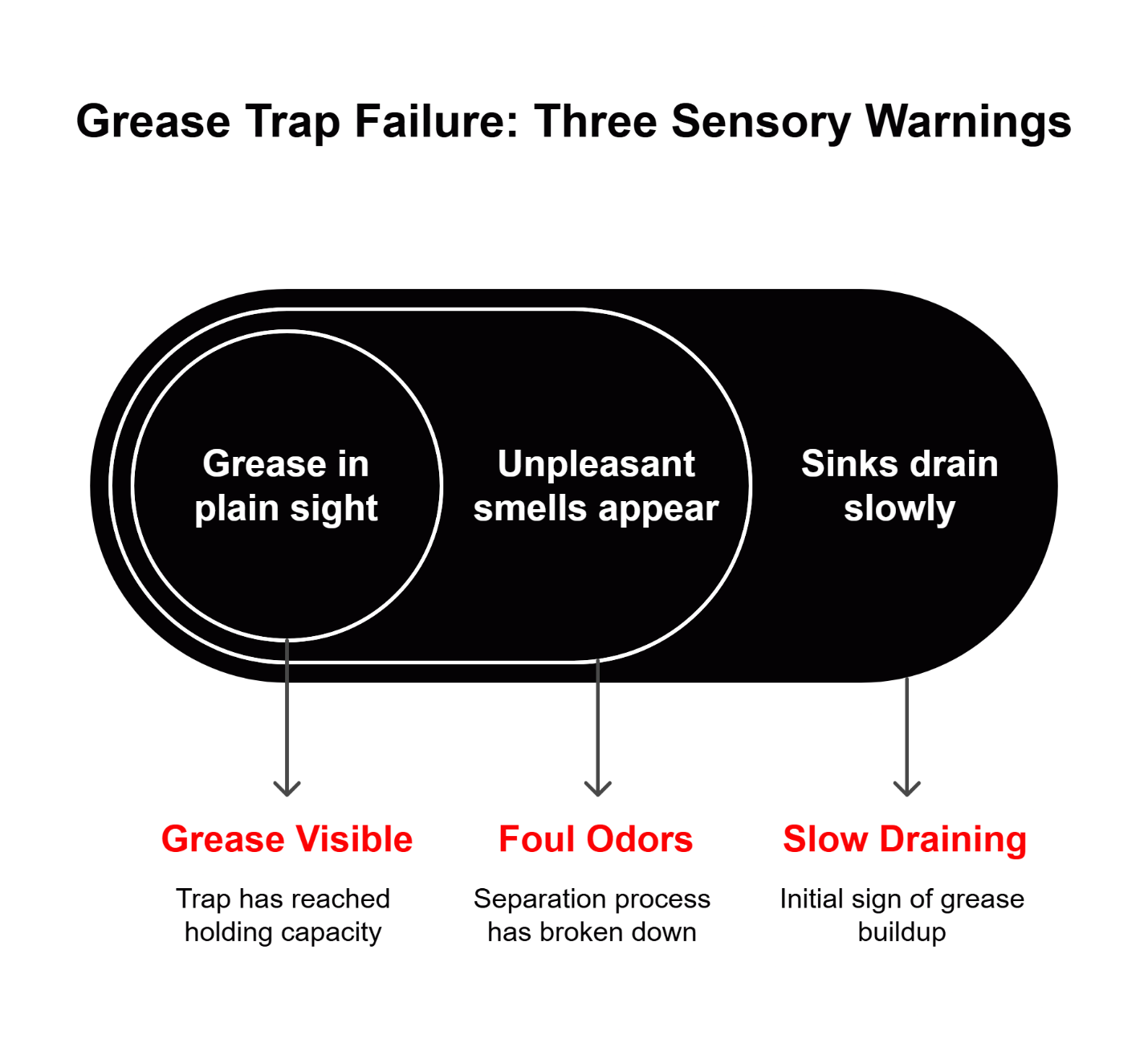

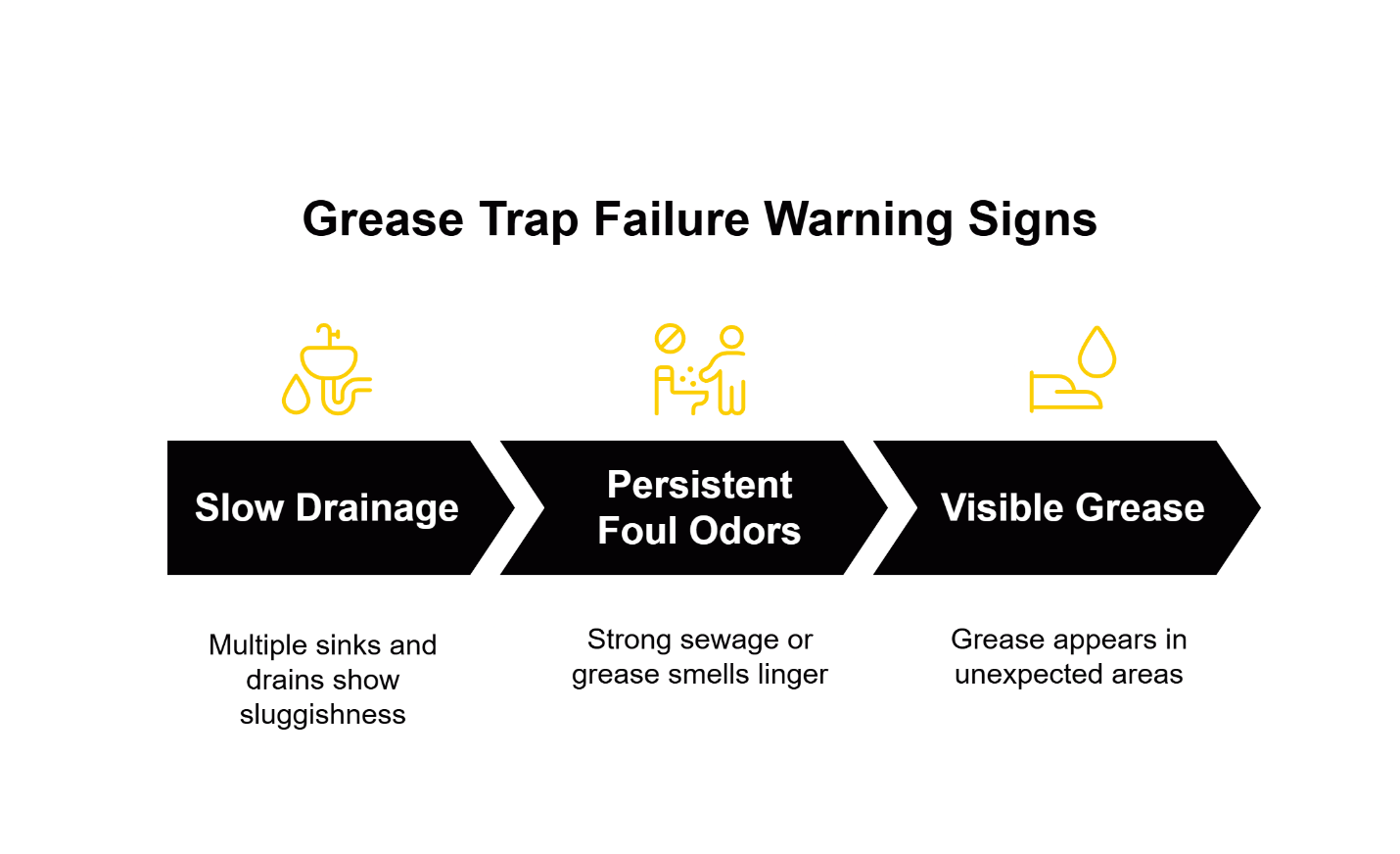

What are signs you need service sooner than scheduled?

Slow drainage throughout the kitchen, persistent odors near the trap area, or visible grease accumulation in sink areas indicate the need for immediate service. Changes in menu offerings, increased customer volume, or extended busy periods may also require temporary schedule adjustments to prevent operational disruptions.

Do you accept hazardous waste or provide drop-off services?

Drane Ranger provides on-site service for non-hazardous wastewater only. We do not accept hazardous materials or provide drop-off facilities. Our grease, grit & lint traps service focuses on scheduled maintenance that keeps restaurant operations running smoothly while ensuring proper waste handling and disposal.

Taking Control of Your Kitchen’s Critical Systems

The difference between reactive and proactive grease trap management often determines whether a restaurant thrives during busy periods or faces costly shutdowns at the worst possible moments. By treating grease trap maintenance as operational insurance rather than deferred expense, Houston restaurant operators transform a hidden risk into a predictable, manageable aspect of successful operations.

Professional service providers like Drane Ranger help restaurant managers focus on what they do best—creating exceptional dining experiences—while ensuring critical infrastructure operates reliably behind the scenes. Our comprehensive approach includes complete cleaning, proper documentation, and ongoing support that helps restaurants maintain compliance and operational stability.

Ready to protect your Houston restaurant from unexpected shutdowns? Contact us today to discuss a maintenance schedule that fits your operation’s specific needs, or call us directly at 281-489-1765 to get started with reliable grease trap service.

Disclaimer This guide is for informational purposes only and does not constitute legal or permit advice. Drane Ranger helps Houston restaurants stay inspection-ready by providing documented, non-hazardous wastewater service.

Our Editorial Process

Every Insights Team article is reviewed for clarity and usefulness to busy operators. We update core guides as standards and best practices evolve.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.