📌 Key Takeaways:

Houston restaurants can avoid costly violations by understanding that compliance isn’t just about calendar dates—it’s about monitoring actual grease levels and maintaining proper documentation.

The 25% Rule Trumps the Calendar: Your grease trap needs service whenever floating grease plus settled solids reach 25% of total liquid capacity, even if it’s only been 30 days since your last pump-out.

Documentation Is Your Defense: Keep five-year records of every trip ticket with transporter registration numbers, waste volumes, and disposal facility details—inspectors will ask for them and missing paperwork triggers violations.

Partial Solutions Create Full Problems: Skimming grease or partial pump-outs don’t reset your compliance clock and can accelerate accumulation patterns that lead to faster violations.

Only Registered Transporters Count: Using an unqualified hauler creates compliance gaps that result in violations even when the physical cleaning was done correctly.

Additives Are Prohibited Shortcuts: Enzyme treatments and grease-eating products that emulsify FOG to pass through your trap violate TCEQ regulations and don’t replace required pump-outs.

Monitor monthly, document everything, and schedule proactively—these three habits prevent surprise violations and keep your kitchen running.

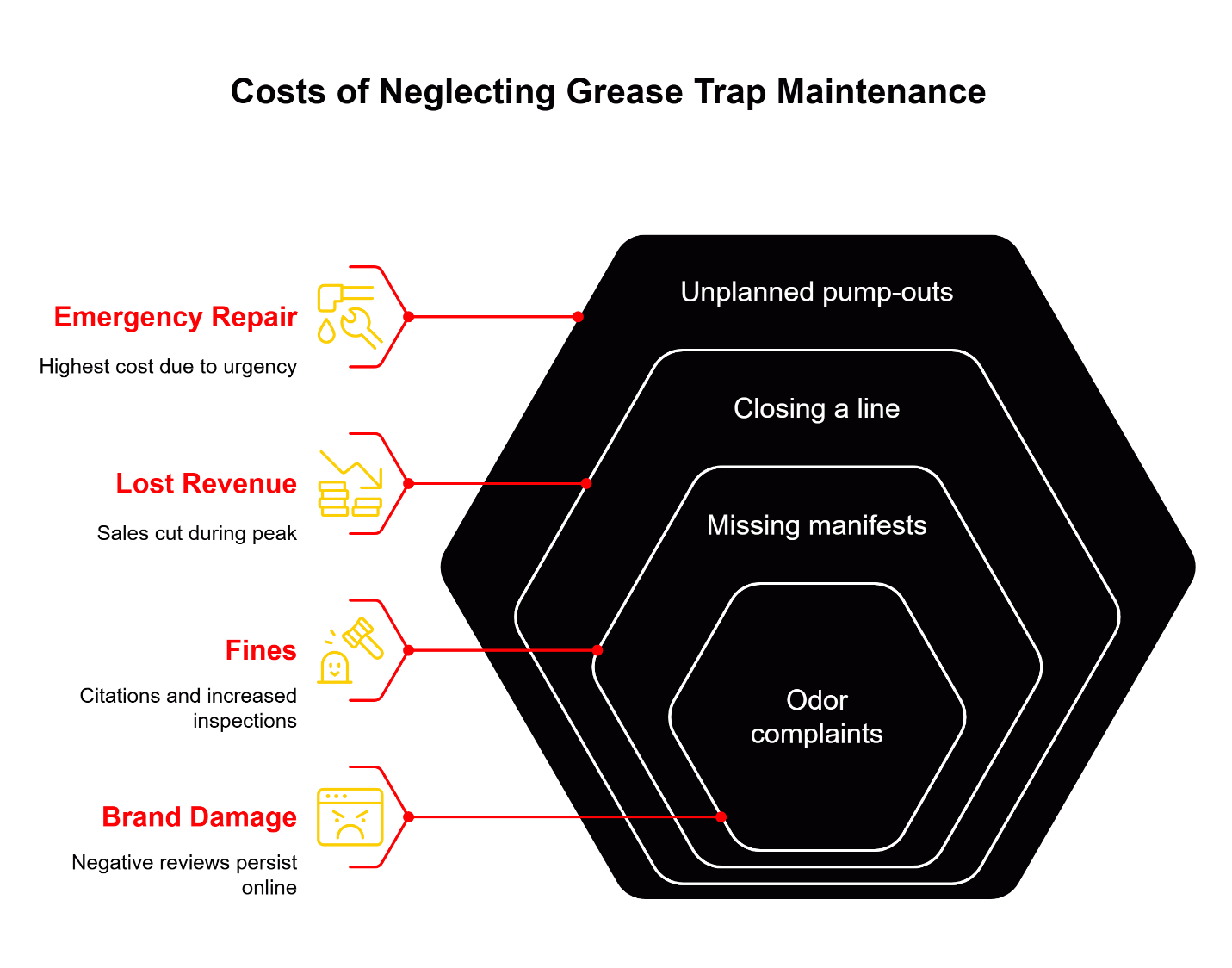

A full grease trap can shut down your kitchen faster than a broken fryer.

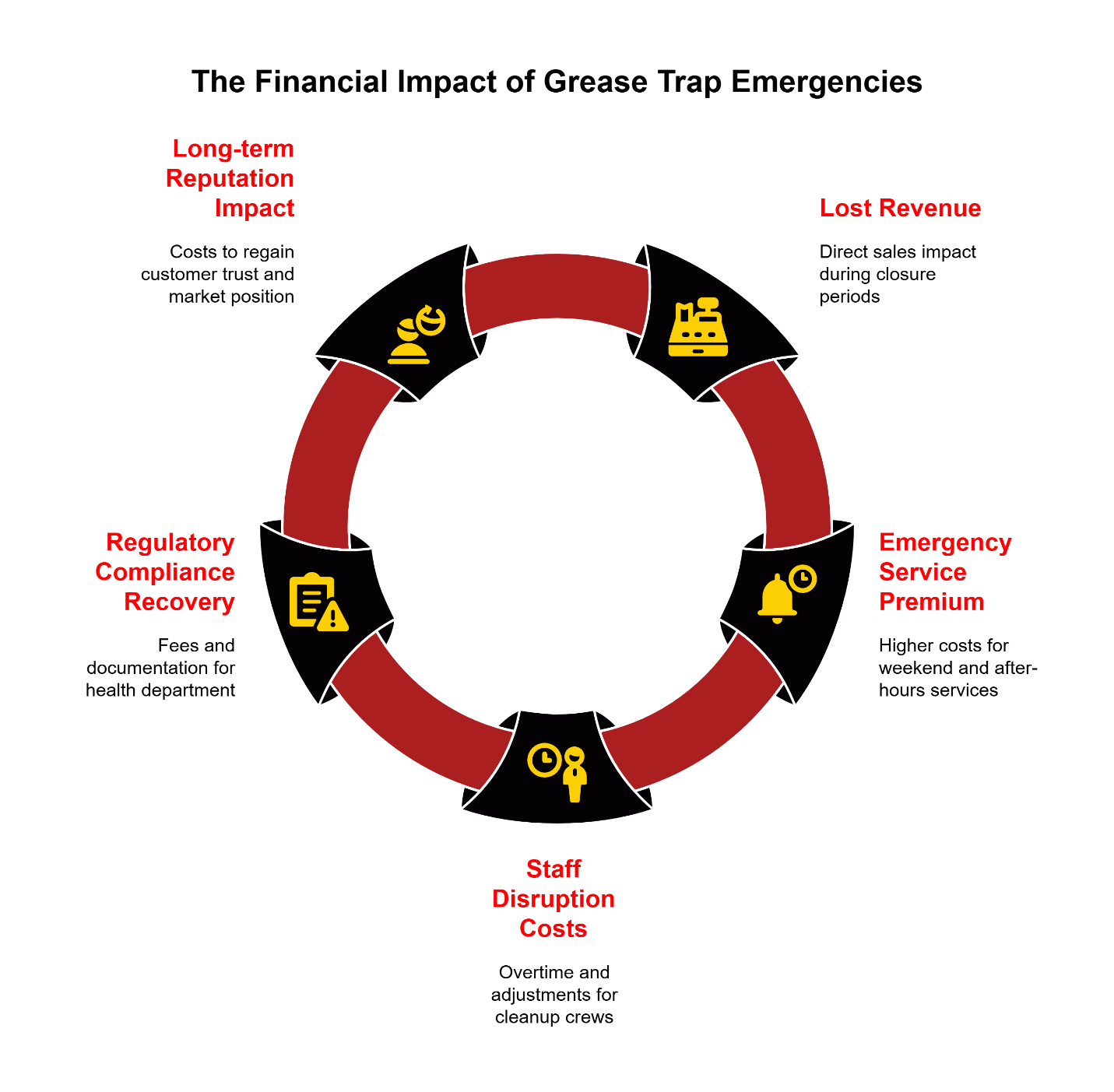

Picture this: It’s Friday night, your dining room is packed, and the city inspector walks through your kitchen door. You’ve been diligent about your quarterly pump-outs, kept your receipts organized, and trained your staff on proper grease disposal. You’re confident you’re compliant. Twenty minutes later, you’re staring at a violation notice that could cost thousands in fines and force you to close until corrections are made.

You followed the rules—or so you thought. The reality is that many Houston restaurant operators unknowingly operate under compliance myths that can trigger violations even when they believe they’re doing everything right. These misconceptions about FOG (Fats, Oils, and Grease) regulations don’t stem from negligence but from incomplete understanding of how local enforcement actually works.

Quick Answer: Food-service establishments should fully pump grease traps at least every 90 days—or sooner whenever total grease plus solids reach 25% of the trap’s wetted depth. Each pump-out should be a complete evacuation, performed by a TCEQ-registered transporter, and accompanied by a five-part manifest kept on file for five years.

This guide exposes four persistent myths that trip up well-intentioned restaurant managers and provides the practical knowledge needed to maintain genuine compliance in Houston’s regulatory environment.

In Houston, FOG compliance isn’t just about sticking to a calendar date. The city’s enforcement approach considers both time intervals and actual grease accumulation levels, which means your trap might need attention before your scheduled quarterly service. Understanding the interplay between baseline requirements and threshold-based triggers can help you avoid the surprise violations that catch even careful operators off guard.

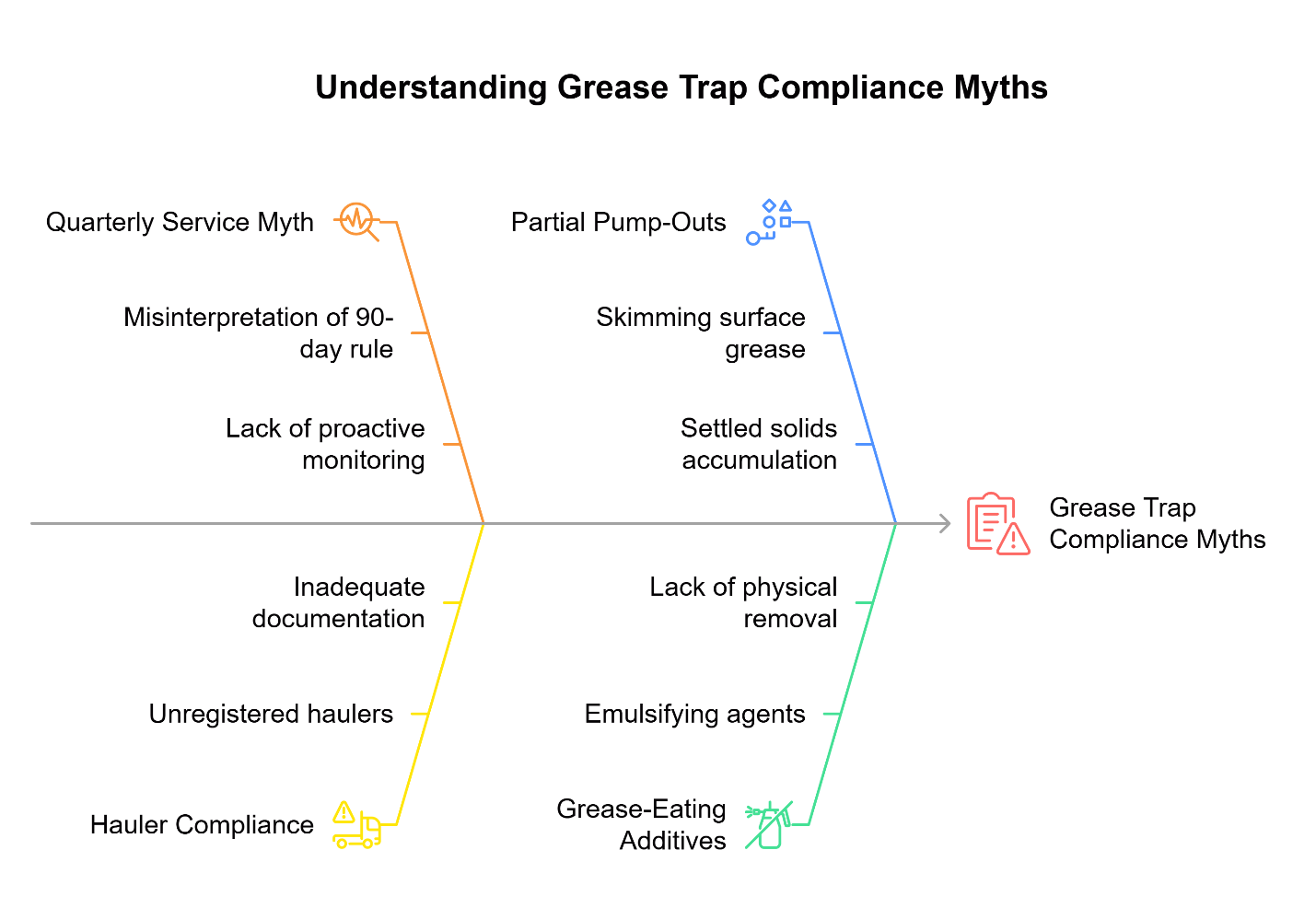

Myth #1: “If We Pump Every 90 Days, We’re Automatically Compliant”

The Reality: Quarterly service establishes your baseline compliance schedule, but the 25% rule requires service whenever the combined depth of floating grease and settled solids reaches 25% or more of the trap’s total liquid capacity.

Houston’s FOG ordinance follows Texas statewide TCEQ model standards that set quarterly cleaning as the minimum standard for commercial grease interceptors. However, this 90-day schedule represents a baseline rather than a guarantee of compliance. The 25% rule requires service whenever the combined depth of floating grease and settled solids reaches 25% or more of the trap’s wetted height.

This threshold-based approach reflects operational reality in busy commercial kitchens. High-volume restaurants can exceed the 25% threshold well before their scheduled quarterly service, particularly during peak seasons or after menu changes that increase grease production.

Why This Creates Risk in Houston: City inspectors measure grease accumulation levels during routine checks, regardless of when your last service occurred. A trap that was pumped 60 days ago but has reached 30% capacity will trigger a violation citation, even though you’re technically “ahead of schedule” on your quarterly maintenance. Local pretreatment programs use these statewide TCEQ standards to protect publicly owned treatment works.

What to Do Instead: Set a standing service cadence and measure grease depth monthly using a sludge judge or coordinate with your service provider. If measurements approach 20%, schedule a pump-out proactively rather than waiting for your calendar date. Document these readings alongside your service records.

Regular grease trap cleaning services in Houston can help establish a monitoring routine that accounts for your kitchen’s specific grease production patterns.

Myth #2: “Any Hauler Can Pump Our Trap—The Manifest Is Optional”

The Reality: Only TCEQ-registered transporters can legally haul grease waste, and proper trip tickets serve as your primary compliance documentation during inspections.

Each pump-out must be accompanied by a manifest or “trip ticket”—a five-part form that records generator details, transporter registration number, waste volumes, receiving facility information, and signatures at each handoff. A copy must be returned to the generator within 15 days and retained for five years.

Not all waste haulers maintain the registration and permits required for grease waste transport. Using an unqualified hauler creates a documentation gap that can result in violations even when the physical cleaning was performed correctly. Additionally, some haulers provide minimal or inadequate trip ticket documentation that doesn’t meet regulatory standards.

Why This Matters for Houston Restaurants: City inspectors routinely request trip ticket copies during compliance checks. Missing or incomplete paperwork often triggers violation notices regardless of your actual cleaning frequency. These documents must show generator information, waste volume, transporter TCEQ registration numbers, disposal facility details, and service dates.

What to Do Instead: Verify that your grease trap service provider maintains current TCEQ registration for waste transport. Keep a binder or organized digital folder with all manifests and disposal receipts, indexed by date and location. Train managers on what fields must be present before accepting a service report. Store these documents in an accessible location where they can be quickly retrieved during inspections.

Myth #3: “Skimming or Partial Pump-Outs Are Fine Between Services”

The Reality: Each service must completely evacuate the trap, with additional truck capacity arranged as needed so the trap is fully emptied within 24 hours if necessary.

Full evacuations prevent residue and backups while supporting operational stability. Complete removal ensures that settled solids and grease layers are entirely extracted, preventing the accumulation patterns that lead to premature capacity issues. TCEQ standards require full evacuation of all contents during each service.

Some operators attempt to extend time between full services by having staff skim surface grease or hiring services to perform partial pump-outs. These approaches fail to address settled solids in the trap bottom and don’t generate the proper documentation that regulatory compliance requires.

Why This Creates Problems: Partial removal doesn’t reset your 25% accumulation measurement. Settled solids remain in the trap, and grease layers rebuild on top of existing residue. This creates accelerated accumulation patterns that can trigger violations sooner than normal operational cycles would suggest. Incomplete pump-outs allow solids to harden, reduce effective volume, and push grease downstream—problems inspectors identify quickly.

What to Do Instead: Use a TCEQ-registered transporter and verify that the service was a full evacuation on the manifest and invoice before signing. Schedule full evacuation services that completely empty your grease trap, and ensure each service includes proper waste transport manifests and disposal documentation.

Myth #4: “Grease-Eating Additives Can Replace Regular Pumping”

The Reality: Introducing surfactants, solvents, or enzymes that emulsify grease so it passes through the trap is prohibited under TCEQ regulations.

TCEQ model standards explicitly prohibit additives that emulsify grease and allow it to pass through the interceptor. Bioremediation products require explicit approval and testing that proves they don’t increase downstream loadings to the treatment facility. These products do not replace the 90-day or 25% pumping requirements.

Some suppliers market enzyme treatments or bacterial additives as alternatives to regular pump-outs. While certain approved biological treatments may help with odor control or minor maintenance between services, no additive can substitute for physical removal of accumulated FOG and solids.

Why This Creates Risk: Using prohibited emulsifying agents can result in violations for improper pretreatment and may damage downstream collection systems. Additionally, operators who rely on additives often skip proper monitoring, leading to trap capacity issues that trigger the 25% rule.

What to Do Instead: Focus on source control methods like scraping plates thoroughly, wiping cookware before washing, and installing drain screens. Confirm proper capture with regular 25% rule checks, and maintain the pumping schedule that matches your actual loading patterns.

How to Self-Check the 25% Rule

This four-step process helps restaurant managers monitor grease accumulation between scheduled services:

- Allow Trap to Settle Let the trap rest so grease floats to the surface and solids settle to the bottom. This provides the most accurate measurement of accumulated materials.

- Measure Wetted Height Measure the total depth from the tank bottom to the outlet pipe invert. This represents your trap’s total liquid capacity.

- Gauge Accumulated Layers Use a sludge judge or coordinate with your service provider to measure the combined thickness of the top grease layer plus bottom settled solids.

- Calculate and Act If the combined grease and solids equal or exceed 25% of the wetted height, schedule an immediate full pump-out. Don’t wait for the next calendar date.

For comprehensive compliance guidance, reference our Houston restaurant FOG compliance checklist which covers additional operational considerations.

Frequently Asked Questions

How often should a grease trap be pumped in the Houston area?

At minimum, every 90 days, and sooner if the 25% threshold is reached. Waivers to extend frequency are case-by-case and require defensible data showing consistent compliance with all discharge limits.

What must be on a grease trap trip ticket and how long do I keep it?

Complete trip tickets include generator and transporter information (including the transporter’s TCEQ registration number), type and amount of waste, receiving facility details, dates, signatures, and a consecutive tracking number. One copy returns to the generator within 15 days; retain it for five years.

Can staff skim between services to delay pumping?

Surface skimming doesn’t address settled solids or satisfy full evacuation requirements. This approach can accelerate accumulation patterns and doesn’t generate proper compliance documentation.

Who is allowed to haul my grease waste?

Only a TCEQ-registered transporter can legally haul grease waste. This registration status is defined in the model standards and enforced at the state level.

Resources

For regulatory compliance and additional guidance:

Authority Sources:

- TCEQ Model Standards for Grease Management – Official cleaning frequency, 25% rule, and manifest requirements

- Texas Administrative Code §312.145 – Recordkeeping and retention requirements

- TCEQ Transporting Waste in Texas Guide – Transporter registration and requirements

- City of Houston Generator Responsibilities – Local implementation of FOG management

Trust Indicators:

About the Drane Ranger Insights Team

Our editorial process combines industry expertise with practical field experience to provide restaurant operators with actionable compliance guidance. Content is reviewed by certified waste management professionals familiar with Houston’s regulatory environment and Texas statewide standards.

Our Editorial Process

All content undergoes multi-stage review including technical accuracy verification against TCEQ model standards, local regulation compliance checking, and practical application testing. We distinguish between verified regulatory requirements and generally accepted industry practices to help operators understand certainty levels.

This content is provided for informational purposes and represents current Texas regulatory standards applicable to establishments in the Houston area. Always follow any site-specific directions on permits or from local pretreatment programs.