📌 Key Takeaways

Grease traps capture floating FOG from kitchens; grit traps capture sinking sediment from wash bays—mixing them up causes backups, compliance violations, and costly downtime.

- Function Determines Location: Grease traps sit near kitchen drains to catch fats and oils, while grit traps install at wash bays to capture sand and heavy solids before they damage pipes.

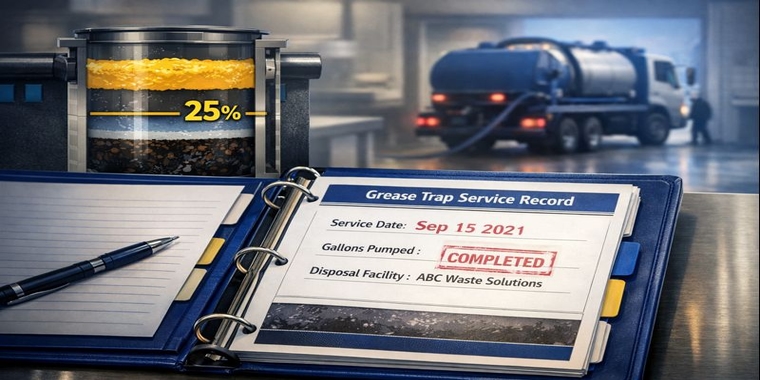

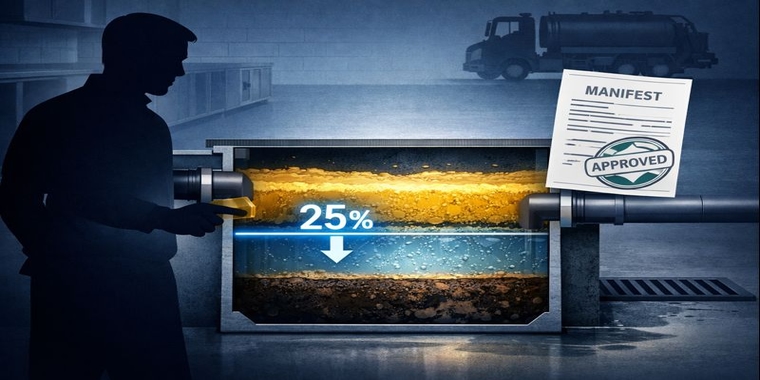

- The 25% Rule Governs Timing: Houston requires cleaning when FOG or sediment reaches 25% of trap depth, not just at the 90-day administrative deadline—high-volume sites often hit this threshold in 45–60 days.

- Manifests Prove Compliance: Invoices show payment; manifests document what was removed, where it went, and who disposed of it—regulators require the latter during inspections, not the former.

- Multi-Use Properties Need Both: Facilities combining food service with vehicle washing require separate grease and grit trap systems, each with independent service schedules and distinct documentation requirements.

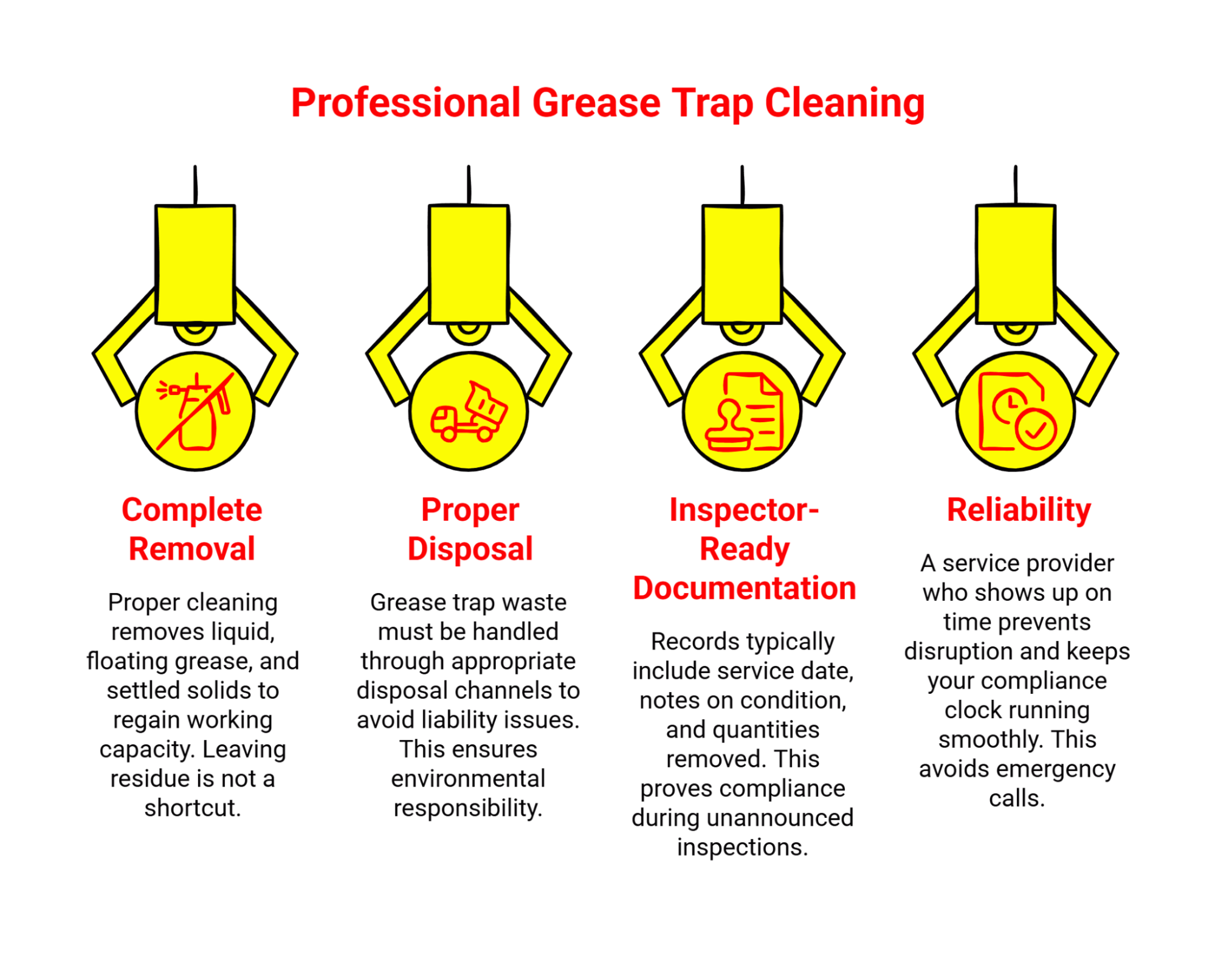

- Professional Service Means Total Evacuation: Complete trap service removes all material and cleans hardened deposits on walls and baffles, not just surface skimming—partial removal accelerates the next fill cycle.

Documentation isn’t paperwork; it’s license protection.

Commercial kitchen operators, car wash managers, and multi-use facility owners will gain clarity on compliance requirements here, preparing them for the identification checklist and service scheduling guidance that follows.

The equipment room hums. Water flows. Everything seems fine—until it isn’t.

A backed-up drain during lunch rush. Foul odors creeping into the dining area. A car wash bay flooded with standing water. These aren’t random equipment failures. They’re the predictable result of treating two completely different wastewater systems as if they were the same thing.

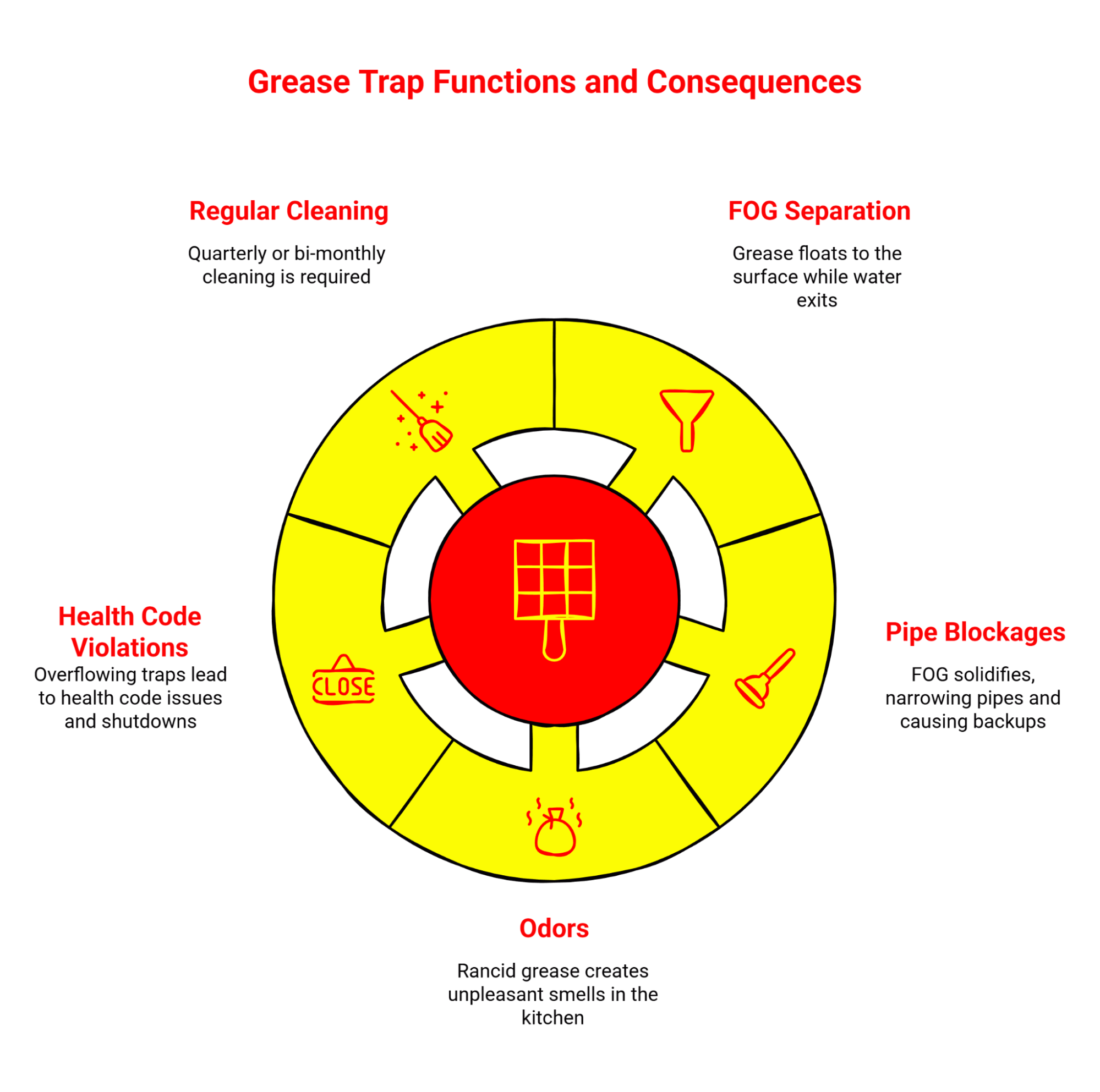

A grease trap separates fats, oils, and grease from kitchen wastewater before they solidify in sewer lines. A grit trap captures sand, dirt, and sediment from wash water before these abrasive materials damage pipes and pumps. The distinction matters because the wrong maintenance approach leads to backups, odors, downtime, and compliance violations.

If you operate a commercial kitchen, you need grease trap cleaning in Houston. If you run a car wash or vehicle maintenance facility, you need grit trap cleaning in Houston. Properties with both operations require both services on separate schedules with different documentation requirements.

Grease Traps: Capturing FOG Before It Hardens

Kitchen wastewater carries fats, oils, and grease—commonly called FOG in the industry. This material floats on water and remains liquid when warm. As it cools while traveling through plumbing, it solidifies and adheres to pipe walls. Without intervention, FOG accumulation narrows pipes, restricts flow, and eventually creates complete blockages.

A grease trap provides that intervention by slowing wastewater flow and allowing FOG to separate and float to the surface while cleaner water exits through a submerged outlet. The trap holds the separated grease until professional removal.

Commercial kitchens typically use one of two configurations. Under-sink grease traps, typically rated for 20 to 50 pounds (approximately 10 to 25 gallons) flow capacity, serve smaller operations like cafes or food trucks. These compact units install directly under three-compartment sinks to manage lower volumes. Larger restaurants and institutional kitchens use outdoor interceptors—tanks holding 500 to 2,000 gallons or more—buried outside the building and connected to multiple kitchen drains.

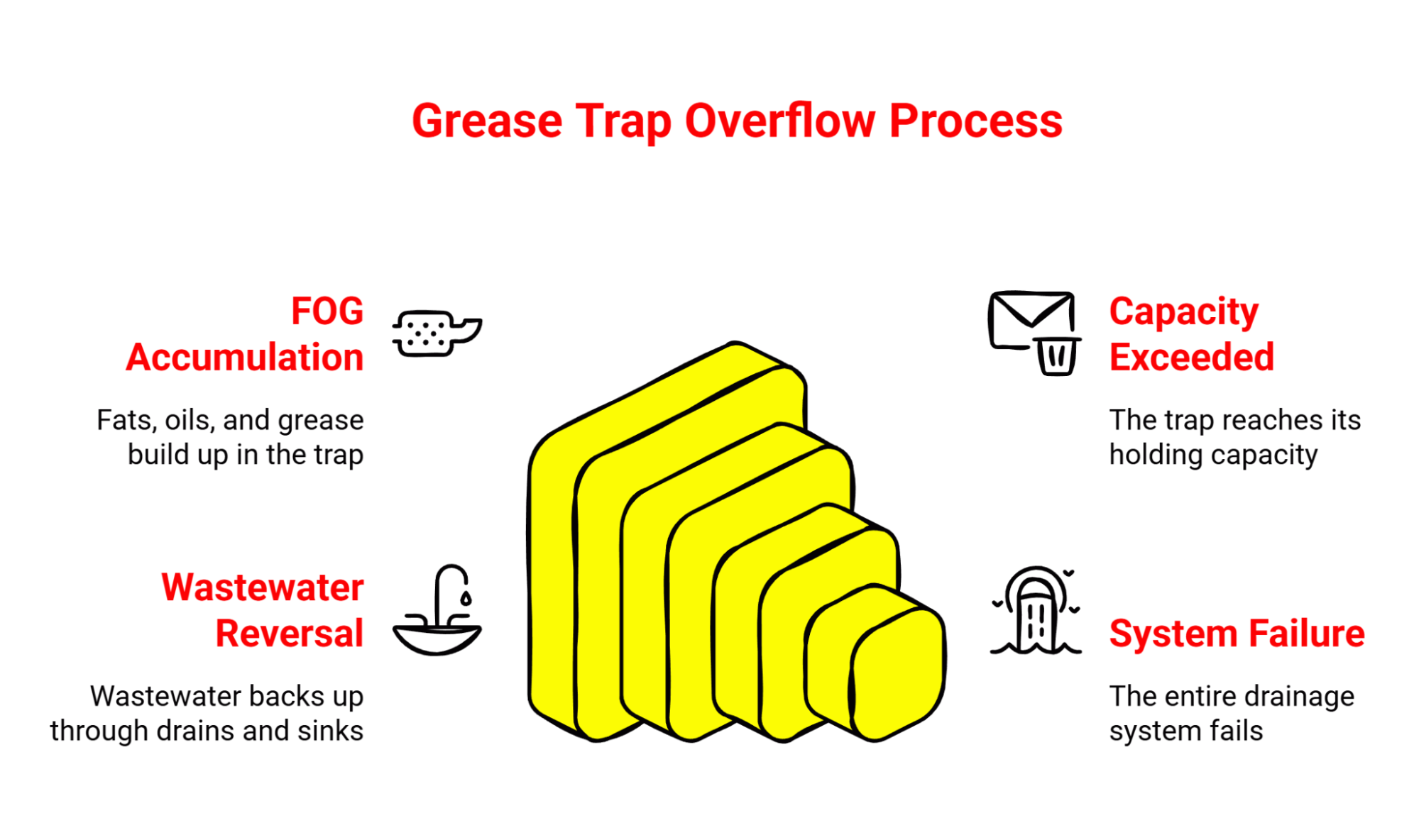

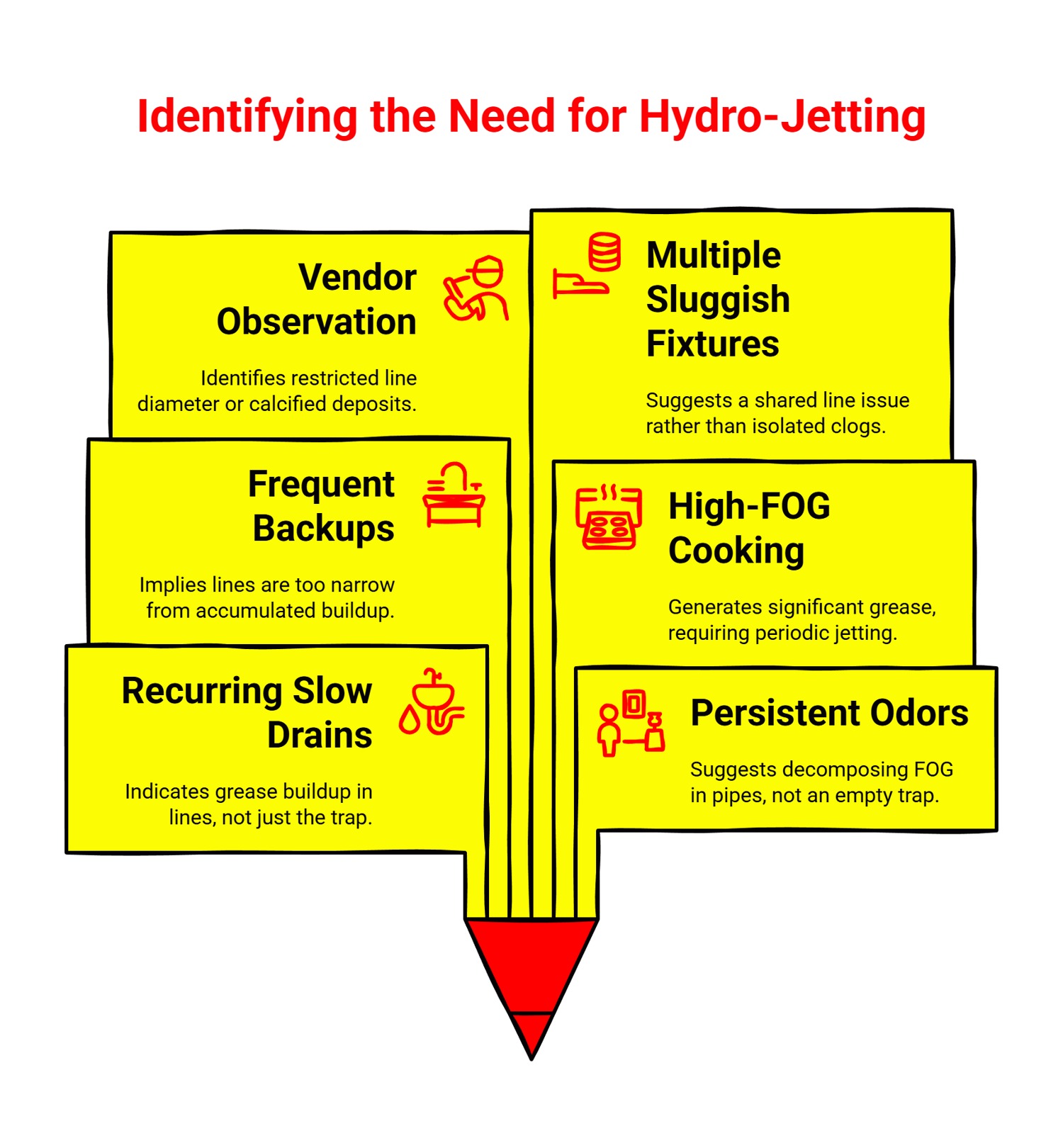

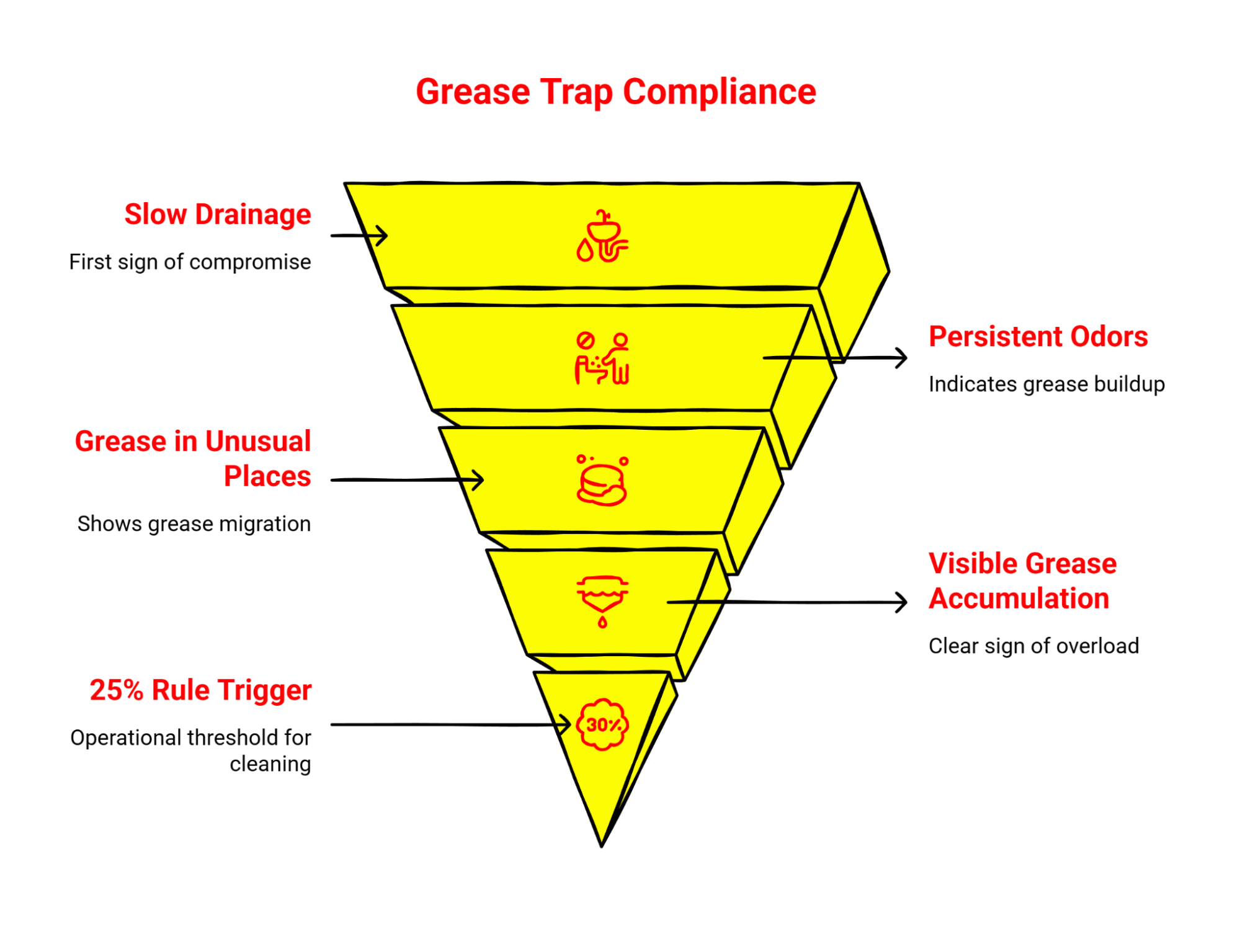

When a grease trap approaches capacity, the first symptom is usually slow drainage. Water pools in sinks and takes noticeably longer to clear. The next stage brings odors—the distinctive smell of rancid grease that spreads through the kitchen and potentially into customer areas. If the situation continues without service, the trap overflows and forces wastewater back into the operation, creating a health code violation and forcing immediate shutdown.

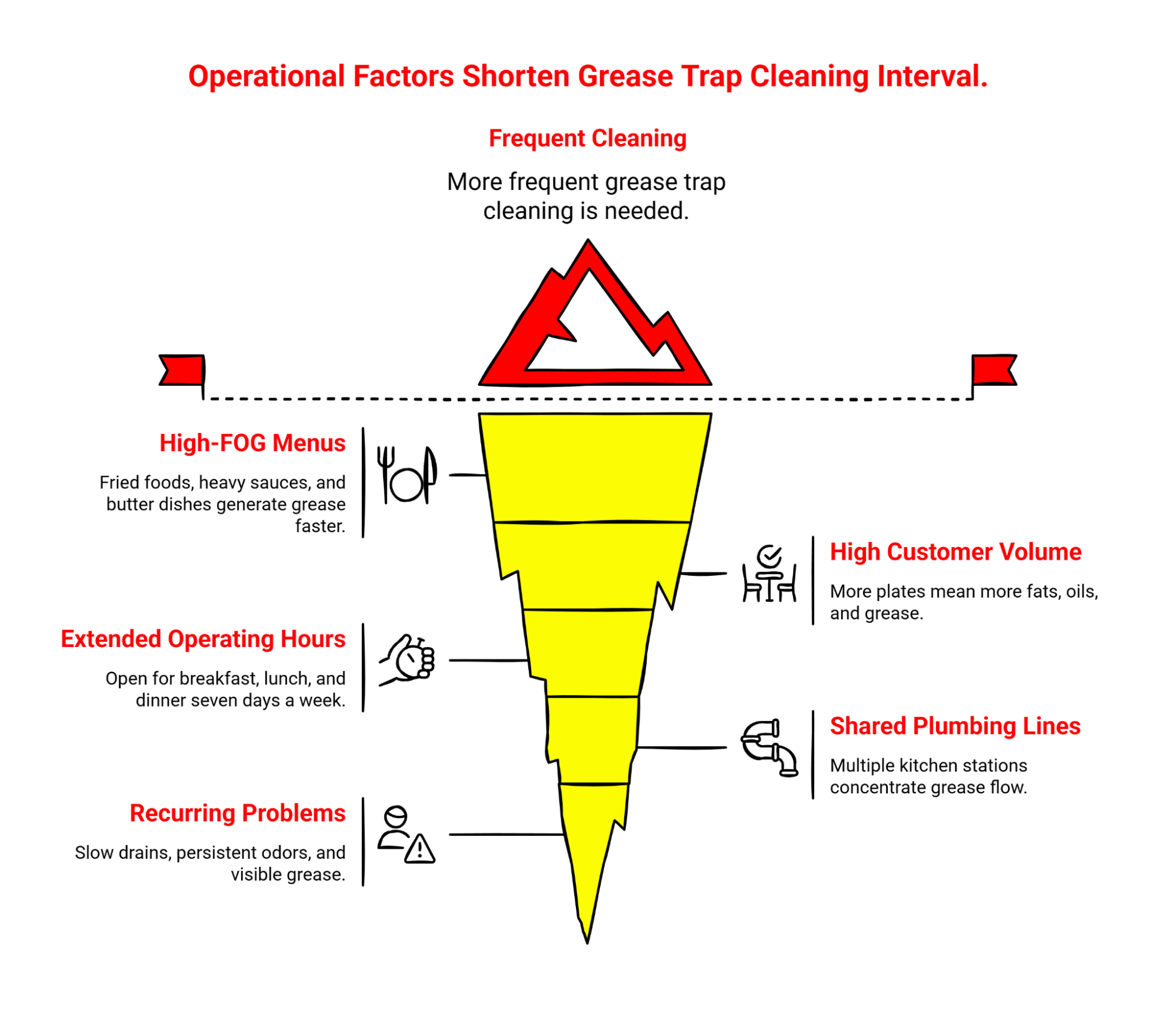

Houston regulations commonly require quarterly grease trap cleaning for commercial food service operations. High-volume kitchens often need service every 60 days based on their FOG production rates.

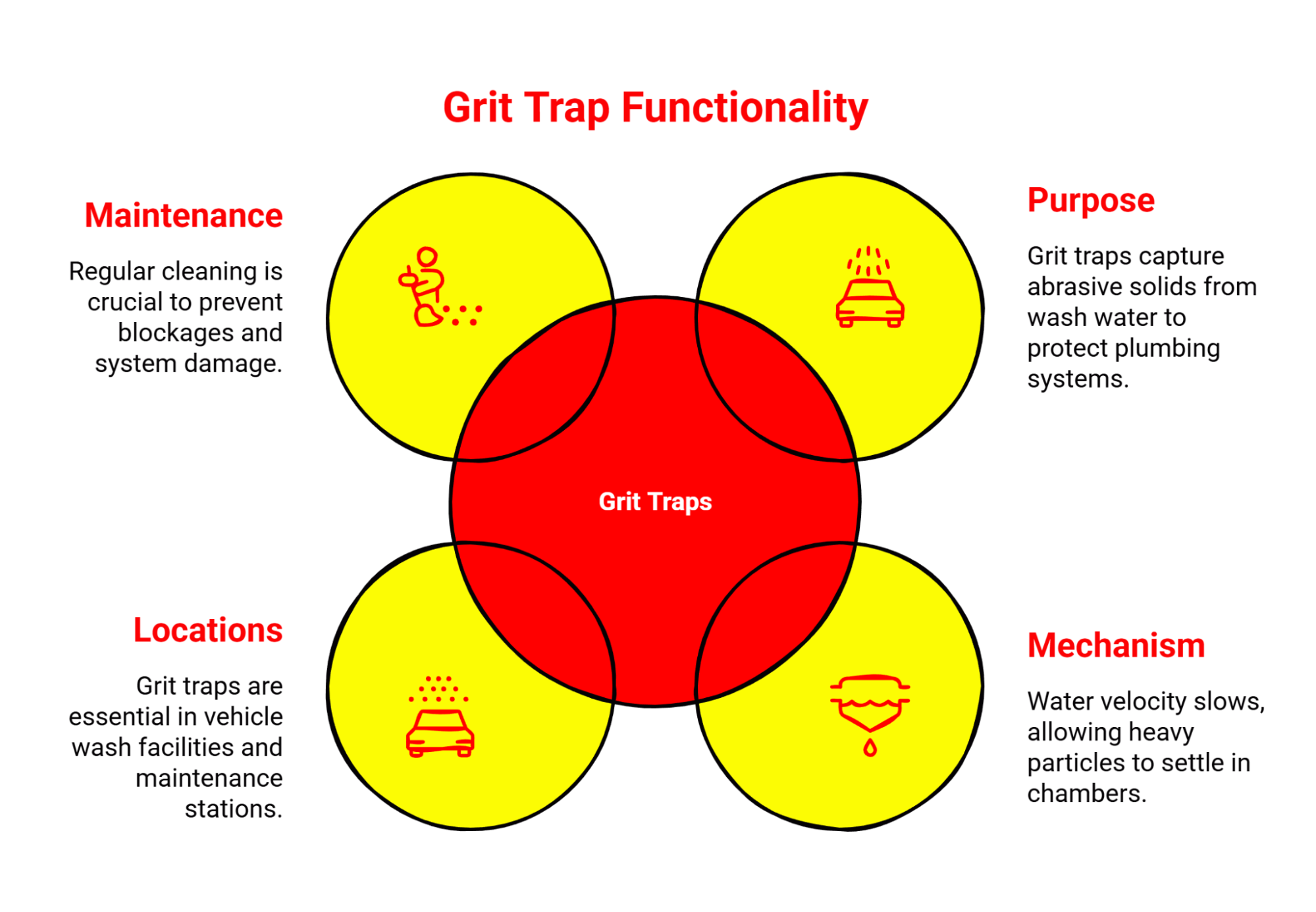

Grit Traps: Stopping Solids That Sink

While grease floats, grit sinks. This fundamental difference shapes everything about how grit traps function and why they appear in different locations than grease traps.

Vehicle washing generates water loaded with sand, dirt, mud, and other heavy particles. These materials are abrasive. When they flow through plumbing systems, they scour pipe interiors, clog valves, and damage pump impellers. A grit trap captures these solids by providing a chamber where water velocity slows enough for heavy particles to settle to the bottom.

Car washes, vehicle dealerships with wash operations, fleet maintenance facilities, and equipment cleaning stations all rely on grit traps. The typical installation places the trap between the wash area and the connection to the municipal sewer system.

Standard grit traps typically utilize a two-chamber design, though configurations can vary based on facility age and specific discharge permits. In the two-chamber setup, water enters the first chamber, where heavy solids settle. A crossover pipe near the top allows cleaner water to flow into the second chamber for additional settling before exiting through the outgoing pipe. This design provides two opportunities to capture solids before they reach downstream systems.

Houston’s landscape and climate can contribute to faster grit accumulation than operators might expect if they’ve worked in other regions. The sandy soil common in the area means vehicles often carry more grit into wash bays. While city regulations typically mandate quarterly service at minimum, many high-volume locations schedule cleaning every 60 days or more frequently to prevent system strain.

Visual inspection reveals grit trap problems. Unequal water levels between the two chambers indicate a clogged crossover pipe. If both chambers show rising water that won’t drain, the outgoing pipe likely has a blockage. When you can see the bottom of the trap filling with accumulated sand and sediment, service is overdue.

Side-by-Side Comparison

| System | Captures | Source | Common Locations | Warning Signs | Service Frequency | Required Documentation |

| Grease Trap | Fats, oils, grease (FOG) | Kitchen sinks, dishwashers, prep stations | Restaurants, cafeterias, hotel kitchens, food service operations | Slow drains, rancid odors, visible grease accumulation, wastewater backups | Every 60–90 days; Houston typically requires quarterly minimum for commercial kitchens | Signed manifests showing removal date, volume, disposal location, and hauler information |

| Grit Trap | Sand, dirt, sediment, heavy solids | Vehicle wash water, equipment cleaning runoff | Car washes, dealerships, fleet yards, wash bays | Unequal chamber water levels, clogged crossover or outgoing pipes, visible sediment accumulation | Every 60–90 days; Houston typically requires quarterly minimum; high-volume sites often need more frequent service | Service records, disposal receipts, maintenance logs documenting cleanout dates and findings |

How to Identify Your System

Location provides the first clue. Grease traps sit near kitchen operations—often in a utility room accessible from the kitchen, or in the case of under-sink units, directly beneath the dishwashing area. Grit traps are located near wash bays, typically in an outdoor access pit or underground chamber adjacent to vehicle washing operations.

Use this quick identification checklist:

- Trace the source: Kitchen fixtures and floor drains point to grease trap systems. Wash bay drains and equipment rinse stations point to grit traps.

- Check what accumulates: A thick floating layer suggests FOG. Heavy sediment at the bottom indicates sand and grit.

- Watch the symptoms: Grease issues typically present as foul odors and slow drainage at kitchen fixtures. Grit issues often show as rising water levels, unequal chamber levels, or restricted flow.

- Confirm the footprint: Smaller units are usually near fixtures. Larger interceptors are typically exterior or in-ground installations.

- Consider operations: Properties running both food service and vehicle wash operations may have both systems.

- Review maintenance records: Consistent documentation helps verify which systems are present and when they were last serviced.

The two-system reality: Multi-use properties present a common source of confusion. A truck stop with both a restaurant and a vehicle wash needs both types of traps. An RV park with food service and a dump station may need both systems. A marina with a restaurant and a boat wash faces the same requirement. Each system operates independently, requires different service schedules, and produces different documentation for compliance purposes.

Assuming one service provider can handle both with a single appointment, or that quarterly service for the grease trap also covers the grit trap, creates compliance gaps that lead to failures and violations.

Common Mistakes That Create Predictable Failures

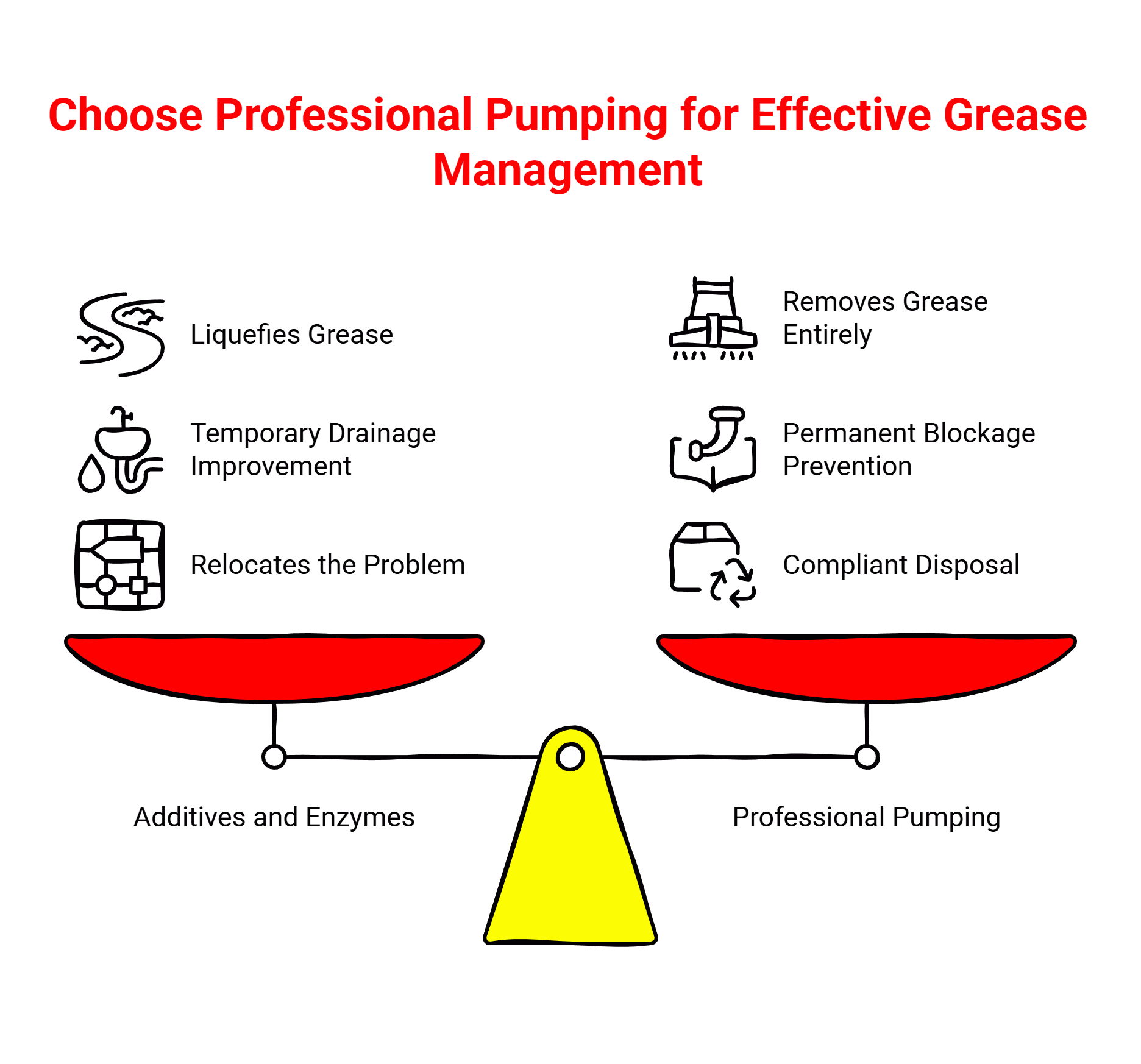

Treating additives as removal

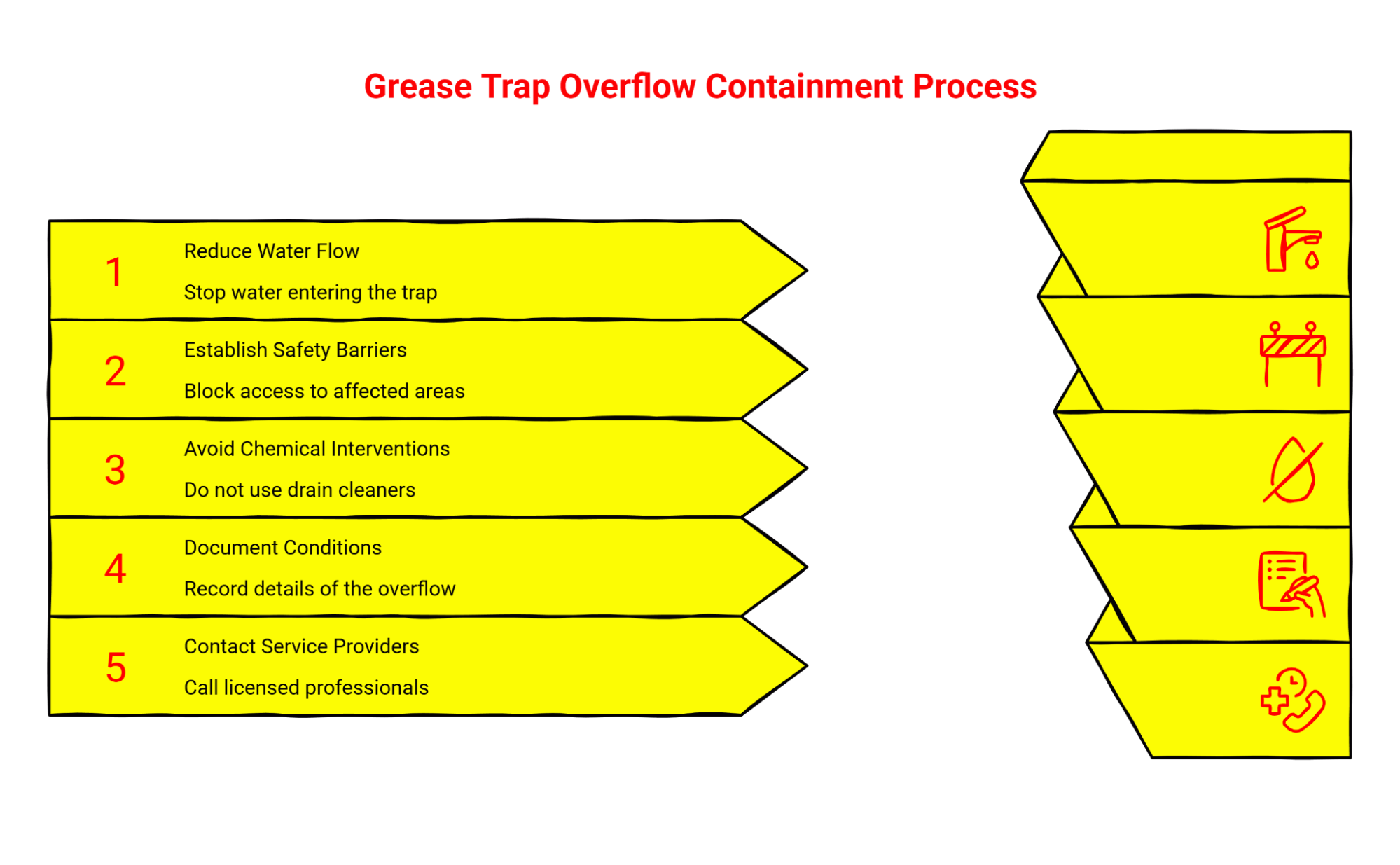

Enzyme treatments, bacterial additives, and hot water flushes can temporarily improve drainage by liquefying FOG or breaking down organic matter. These products don’t remove material from the trap. They move it downstream, where it cools, solidifies, and creates problems in municipal sewer lines or at your property’s connection point.

The same logic applies to grit traps. High-pressure jetting might temporarily clear a clogged pipe, but if the sediment remains in the trap, it will clog again quickly. Professional service physically removes the accumulated material, resetting the trap’s capacity to its original design specification.

Waiting until the deadline

While Houston regulations often adhere to a strict “25% Rule” (cleaning required when FOG/solids reach 25% of wetted depth), the 90-day mark is generally the absolute administrative maximum for permit compliance. Booking service on day 88 or 89 creates unnecessary risk. If the service provider is fully scheduled, if weather delays the appointment, or if the trap requires more extensive cleaning than anticipated, the work may not be completed before the mandated window closes.

Operators should ideally schedule service between day 60 and day 75, or immediately upon reaching the 25% capacity threshold. This buffer ensures compliance even when unexpected complications arise. For high-volume operations, monthly or bi-monthly service eliminates the stress of deadline management entirely.

Confusing invoices with compliance proof

An invoice documents that payment was made for a service. A manifest documents what was removed, how much was collected, where it was transported, and who received it at the disposal facility. During inspections, regulators require manifests. They need proof that waste was handled legally and disposed of at an approved facility.

“It’s not just paper; it’s your license,” explains one Houston operator with two decades of experience managing commercial kitchen compliance. “You pay us to ensure the inspector walks away happy.”

Keep signed manifests on-site for five years minimum. Store them in a dedicated binder organized by date. When an inspector arrives, you should be able to produce complete documentation within minutes. This isn’t administrative overhead—it’s risk management that protects your operating license.

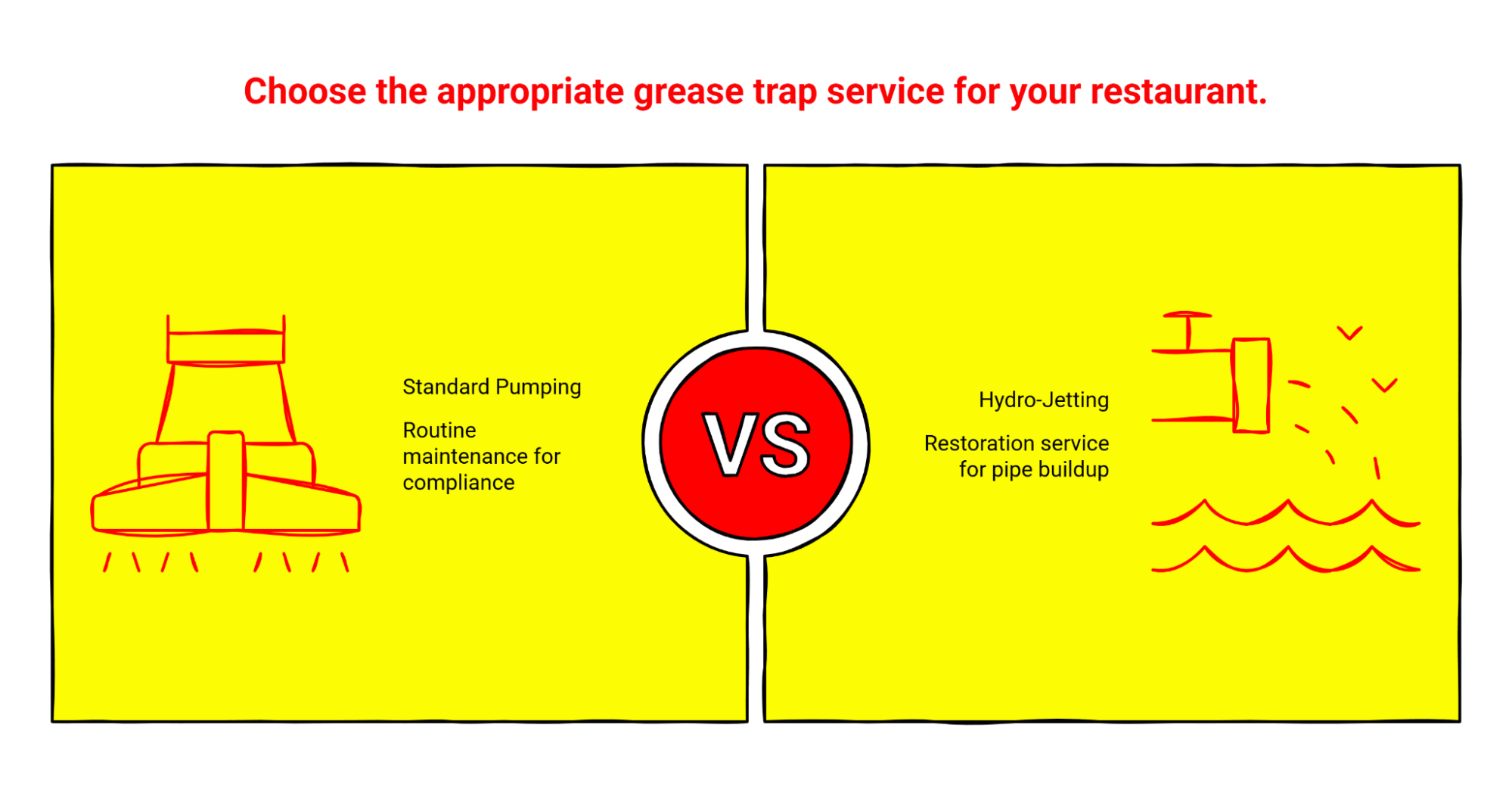

What Professional Service Delivers

Complete grease trap service begins with total evacuation. The service truck’s vacuum system removes all liquid and semi-solid material from the trap, including the layer of FOG floating on top and the accumulated sludge at the bottom. Partial removal—skimming the top layer or pumping only the liquid—leaves material that reduces effective capacity and accelerates the next fill cycle.

After evacuation, professional service includes cleaning the trap’s interior surfaces. Grease hardens on walls, baffles, and the interior of pipes. This stuck-on material narrows the trap’s effective volume and creates persistent odor problems. High-pressure water, appropriate cleaning agents, or manual scraping removes these deposits.

Grit trap service follows a similar pattern. After removing liquid and loose sediment, technicians address compacted material at the bottom of chambers. Sand and dirt compact over time, forming a solid layer that’s difficult to remove with vacuum equipment alone. This material must be broken up and extracted to restore the trap’s full settling capacity.

Responsible disposal completes professional service. Grease trap waste goes to facilities equipped to process FOG and organic material. Grit trap waste goes to facilities that can separate and process sediment. The manifest documenting this disposal provides proof that waste reached an approved destination through a legal chain of custody.

Scheduling matters for business continuity. Professional providers work during off-peak hours to minimize disruption. For restaurants, this typically means early morning before opening or late at night after closing. For car washes, service happens during slower weekday periods or after hours when the facility is closed.

“Drain Ranger is very professional and reliable. Basically they can take care of all your grease drain needs.” — Shelley M.

Understanding that grease and grit require different approaches is the foundation of effective trap maintenance. For comprehensive service covering both systems, explore our Grease Grit & Lint Traps offerings.

Expert Corner: Compliance Documentation and Inspection Readiness

Houston’s trap cleaning requirements tie directly to documentation outcomes. During inspections, regulators verify not only that traps are clean and functional, but that operators maintain proper records demonstrating consistent compliance over time.

The City of Houston provides guidance on cooking oil and grease management that reinforces the connection between proper disposal practices and regulatory compliance. This documentation serves multiple functions: it proves the cleaning schedule is being executed, demonstrates that the waste stream is being handled responsibly, and provides a paper trail that satisfies inspection requirements.

Inspection readiness improves dramatically when records are easy to retrieve and consistent over time. Operators who can immediately produce organized manifests showing service dates, volumes removed, and disposal facility information face significantly less scrutiny during audits than those who scramble to locate scattered paperwork or rely on invoices alone.

Professional service providers understand this documentation requirement and build it into their standard process. The manifest becomes part of the service deliverable, not an afterthought. This approach transforms trap maintenance from a necessary expense into what one industry veteran calls “business continuity insurance and a compliance shield.”

Requirements can vary by jurisdiction, permit status, and waste stream characteristics. Some operations may need additional documentation depending on their specific circumstances. Consulting with both service providers and local regulatory authorities helps ensure all documentation bases are covered.

When to Schedule Service

Don’t wait for complete system failure. These signs indicate it’s time to call for assessment:

Persistent odors near the trap location or at fixtures connected to it suggest the trap has reached or exceeded capacity. For grease traps, this manifests as rancid, fatty smells. For grit traps, the odor is typically less pronounced but may have a septic or stagnant water quality.

Slow drainage at connected fixtures means flow is restricted somewhere in the system. In kitchens, sinks take noticeably longer to empty. In wash bays, water pools on the floor rather than draining promptly.

Visible problems demand immediate attention. Grease appearing in floor drains or around the trap access point signals overflow risk. In grit traps, visibly rising water levels that don’t equalize between chambers indicate internal blockages.

System alarms on automated monitoring equipment activate when water reaches predetermined levels. These alarms exist to provide advance warning before backups occur. Respond to them promptly rather than silencing them and continuing operations.

Calendar-based scheduling provides the most reliable compliance management. Rather than reacting to symptoms, establish a maintenance plan that schedules service before problems develop. For quarterly requirements, schedule service every 60–75 days. For high-volume operations, monthly service eliminates stress and ensures continuous compliance.

Contact us at 281-489-1765 to schedule an assessment, arrange service, or establish a maintenance plan that matches your operational volume and compliance requirements.

Frequently Asked Questions

Can one facility need both systems?

Yes. Properties that combine food service with vehicle or equipment washing require both grease traps and grit traps. Each system serves its specific wastewater source and cannot substitute for the other. Common examples include truck stops with restaurants and fuel islands, RV parks with food service and dump stations, marinas with dining facilities and boat wash operations, and multi-tenant commercial buildings with both restaurant and automotive tenants. Each system needs independent service scheduling and separate compliance documentation.

What determines how often service is needed?

Houston regulations typically establish a 90-day maximum between services. Actual frequency depends on operational volume. A high-volume restaurant kitchen producing substantial FOG may need service every 45–60 days to prevent capacity issues. A car wash processing hundreds of vehicles daily will accumulate grit faster than a low-volume facility. The best approach combines calendar-based scheduling with capacity monitoring to ensure service occurs before problems develop.

What happens if a trap goes too long without service?

Grease traps that exceed capacity allow FOG to pass through to sewer lines, where it cools and creates blockages. This can cause backups throughout the facility, force wastewater into customer areas, trigger health code violations, and result in citations or operating permit suspension. Grit traps that fill beyond capacity allow sediment to flow downstream, damaging pumps, clogging pipes, and potentially backing up into wash bays. Both scenarios require emergency service, which costs significantly more than scheduled maintenance and often forces temporary operation shutdown.

Is documentation really necessary?

Yes. Houston requires documentation proving that trap waste was collected and disposed of properly. During inspections, regulators verify that facilities maintain manifests showing service dates, volumes removed, disposal locations, and hauler information. Invoices alone don’t satisfy this requirement because they only prove payment occurred, not that waste reached an approved disposal facility. Missing or incomplete documentation can result in citations regardless of whether the trap itself is clean and functional.

How can multi-use facilities avoid confusion?

Create separate maintenance schedules and documentation systems for each trap type. Label traps clearly at their access points—”Grease Trap – Kitchen Drains” and “Grit Trap – Wash Bay” eliminate ambiguity. Work with service providers who understand both systems and can coordinate scheduling efficiently. Maintain separate binders for grease trap manifests and grit trap service records. During inspections, this organization demonstrates that management understands the distinction and maintains each system appropriately.

What should be included in a maintenance plan?

A comprehensive maintenance plan specifies service frequency based on your operational volume, identifies which fixtures drain to which traps, establishes documentation protocols for manifests and service records, includes contact information for emergency service, and sets reminders for scheduling before compliance deadlines expire. The plan should be documented, shared with relevant staff members, and reviewed annually to ensure it remains appropriate as operational volumes change.

For additional trust verification, Drane Ranger maintains accreditation with the Better Business Bureau, demonstrating our commitment to professional service standards and customer satisfaction.

Disclaimer: This article provides general information about grease trap and grit trap systems for educational purposes. It does not constitute professional advice, regulatory interpretation, or specific guidance for your facility’s unique circumstances. Always consult with licensed service providers and local regulatory authorities regarding requirements specific to your operation and location.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the Drane Ranger Insights Team

The Drane Ranger Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.